R

Ideas for my Project 90 Chevy C3500

M

mrhyde

+1y

Good Afternoon peoples of Dually Scene. New to the dually scene, but not new to the automotive scene. Just wanted to introduce myself and get some feedback and ideas from you on my up coming project. I live in Vista, Ca I am a Marine first but on my off time I build Motors for people with in the local drag racing scene, Trophy truck scene, classic hot rods, once in awhile imports but the customers really have to sell me their idea and be interesting enough for me to build them a motor for the imports. I figure that I have a dually and I don't see enough slammed duallies in my area running around. Kinda going with the late 80's early 90's approach with this. Technolgy has come along way from 20 years ago up to this point. And, the aftermarket world has diffently come up to a whole new level. Feel free to give suggestions your imput. And yes I can read (don't ask about cutting semi truck wheels, and on how to post pics). Pics will follow of what the truck is right now.

1990 Chevy C3500 Dually, 7.4L Automatic

-Want to Bag it (with out having to 4 link, 3 link or put in a C-Notch) at least 3 to 4 differant ride heights.

-Mono-Chromatic paint all white with a hint of pearl.

-Smooth bumber front with billet insert.

-Billet Phantom grill covering headlights.

-Roll pan rear with the a flip down plate for a hidden hitch.

-Remove taillights and smooth that out.

-LED brake lights.

-Prostreet look for wheel and tire combo, one wide single wheels in rear 18", with matching 18" front

1990 Chevy C3500 Dually, 7.4L Automatic

-Want to Bag it (with out having to 4 link, 3 link or put in a C-Notch) at least 3 to 4 differant ride heights.

-Mono-Chromatic paint all white with a hint of pearl.

-Smooth bumber front with billet insert.

-Billet Phantom grill covering headlights.

-Roll pan rear with the a flip down plate for a hidden hitch.

-Remove taillights and smooth that out.

-LED brake lights.

-Prostreet look for wheel and tire combo, one wide single wheels in rear 18", with matching 18" front

BB

big bear

+1y

welcome aboard from northeast ohio. great looking start of a project. i like your plans. simple, yet different. well, the hardest part will be the air setup. i dont see you getting around not notching your frame. theres just not that much room. you have any setups in mind? if anybody, air ride technology. there ur best bet for ur likings they do alot of street rod, handling performance side of airride.

M

mrhyde

+1y

I have been looking at youbagit.com, and airide. So many differant stuff out there. You only need to realy C-notch a frame if you really want to lay the frame on the ground. I have connections with national springs in el cajon ca. I gave them the weight of the truck measured in 11 differant ways. They are going to make me a mono leaf for the rear, taking out all the over load springs. Then just add a panhard bar, competion engineering full floating axle kit, and bags. This is what have been told by of a couple of guys that do suspension work on tophy trucks in its all in theory. Sounds great but i need to see it for myself i plan everything out may take me longer. But i am spending the money where it counts i dont plan on laying frame would be cool just going to make a sutle statement.

S

severeddime

+1y

I'm not sure a Mono Leaf would be the way to go.

I had a mono leaf in my bagged S-10 15 years ago when I first bagged it, the spring flex and axle twisting was pretty extreme and all around dangerous, that was with a puny 4.3 V/6. A mono leaf coupled with a big block ( since your a motor guy I can't see you leaving that stock ) and a truck that weighs three times as much before factoring in a trailer would scare me a bit.

I had a mono leaf in my bagged S-10 15 years ago when I first bagged it, the spring flex and axle twisting was pretty extreme and all around dangerous, that was with a puny 4.3 V/6. A mono leaf coupled with a big block ( since your a motor guy I can't see you leaving that stock ) and a truck that weighs three times as much before factoring in a trailer would scare me a bit.

krewzlo

+1y

It seems like a mono spring that would be stiff enough to hold the weight would ride like shat. Agreed on the axle wrap, plus wouldnt need a panhard bar with a leaf spring. Would probably bind things up throughout suspension travel. I would stay away from the mono spring if it was me.

krewzlo

+1y

It seems like a flip kit with over load bags would fit your needs the best. When my truck was brand new I ran a static drop in the front and a flip kit in the rear without using the notch, then added an overload bag kit to lift so I could drive. With out a notch and the bags it was undriveable due to the fact the axle was already hitting the frame. With the bags and no notch i was able to tow my enclosed car hauler with no issues but aways was a bit jacked up in the rear. If you are worried about weakening your frame by notching it, dont worry, unless you hack it up. Use the belltech notch and flip kit and you can tow above what the truck is rated for.

M

mrhyde

+1y

@ Severedime Yea I don't like that idea of the Mono Leaf, and I have came to grips that there is no way around it I am going to have to C-Notch the frame. Thats why National Springs had me weigh the truck 11 differant ways so they can make me a Mono leaf Spring for this app, bolted to a full floating axle kit with reversed axle wrap bars above the leaf spring. @ krewzlo your right on the panhard bar its not needed the full floating kit locates the axle where it needs to go only alowing up and down movement for the mono leaf with the axle wrap bars would take care of the left and right movement of the rearend.

For a Bag kit what does it all inteal that I need?? Do I have to run Spindles up front? Do I have to run leaf springs at all? Can all this be done without having to 4 link or 3 link the rear end?? Old school drag racing setups where done the leaf springs, ladder bar kits, full floating kits and shocks but thats if your going to use leaf springs for launching and traction, I see all the over load bags that go in between the leafs and frame for pay load thats not what I want to do. I want a complete kit that will take out the leafs and coil springs up front and lower and raise the truck 3 differant ride heights. I understand a fixed drop kit simple change springs and spindles up front, under axle spring the rear thats a flip kit put shackles that are longer on the rear leafs relocates the leafs farther up. Boom there you go you have a lowered truck. Will a fixed ride height suck on the drive I want this heavy big to float and ride nice down the road to enjoy the cruise. Not to have my teeth chatter my fillings out from hiting every bump and pot holes that are out here.

For a Bag kit what does it all inteal that I need?? Do I have to run Spindles up front? Do I have to run leaf springs at all? Can all this be done without having to 4 link or 3 link the rear end?? Old school drag racing setups where done the leaf springs, ladder bar kits, full floating kits and shocks but thats if your going to use leaf springs for launching and traction, I see all the over load bags that go in between the leafs and frame for pay load thats not what I want to do. I want a complete kit that will take out the leafs and coil springs up front and lower and raise the truck 3 differant ride heights. I understand a fixed drop kit simple change springs and spindles up front, under axle spring the rear thats a flip kit put shackles that are longer on the rear leafs relocates the leafs farther up. Boom there you go you have a lowered truck. Will a fixed ride height suck on the drive I want this heavy big to float and ride nice down the road to enjoy the cruise. Not to have my teeth chatter my fillings out from hiting every bump and pot holes that are out here.

M

mrhyde

+1y

Update on Anvil

New front rotors, pads, sway bar end links and bushings, upper lower ball joints, upper lower arm bushings, tie rod ends, idler arm, pitman arm, gear box, driveline re-balanced with new u-joints and carrier bearing.

New front rotors, pads, sway bar end links and bushings, upper lower ball joints, upper lower arm bushings, tie rod ends, idler arm, pitman arm, gear box, driveline re-balanced with new u-joints and carrier bearing.

M

mrhyde

+1y

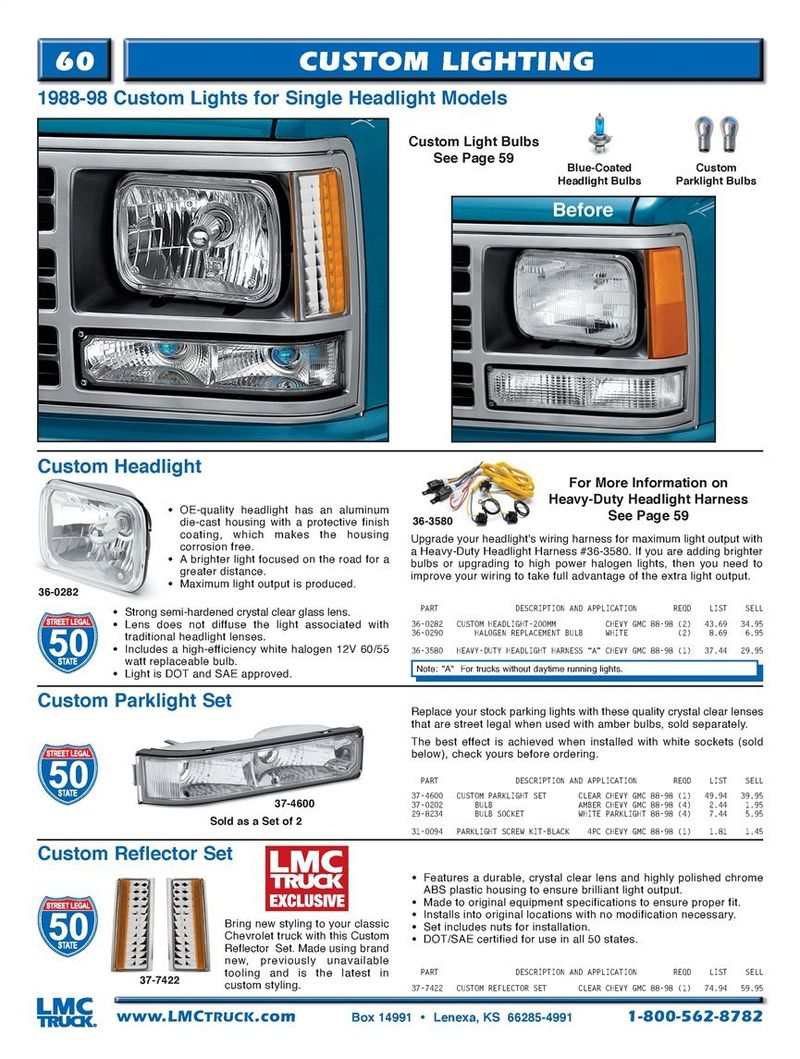

Just ordered all new headlights - Chrome Halo kind plus the wiring that will allow the low beams and high beams be on together when the highbeams are on, plus new door hing bushing kit.

Post was last edited on May 20, 2013 11:29. Edited 2

times.

M

mrhyde

+1y

So here is the new Motor coming from summit racing ATK High performance Engines part # HP45. 454 500 horses/500 foot pounds of torque.

Anybody got any leads on a low miles heavly built TH700R4, or 4L80E?????

Parklight set 37-4600

Headlights 37-7349

I have been busy this weekend. Ordered a new motor for the Dually going to take the old one out 176,000 miles on it. Rebuild it put new gaskit kit, rings, bearings, and so forth then sell it for 3500.00 top to bottom with the TBI setup minus all the exsorize, brackets and ignition system. Anybody intertested let me know probably just knock a couple of hundie off of it if you ask.

Anybody got any leads on a low miles heavly built TH700R4, or 4L80E?????

Parklight set 37-4600

Headlights 37-7349

I have been busy this weekend. Ordered a new motor for the Dually going to take the old one out 176,000 miles on it. Rebuild it put new gaskit kit, rings, bearings, and so forth then sell it for 3500.00 top to bottom with the TBI setup minus all the exsorize, brackets and ignition system. Anybody intertested let me know probably just knock a couple of hundie off of it if you ask.

Related Discussions in General Discussion

Thread

Posts

Last Post

7

last post by

Babyfartzmageezaks530 +1y

5

A

last post by

Alreadyhavingissues +1y