G

measurements for a mandrel bend

G

granth

+1y

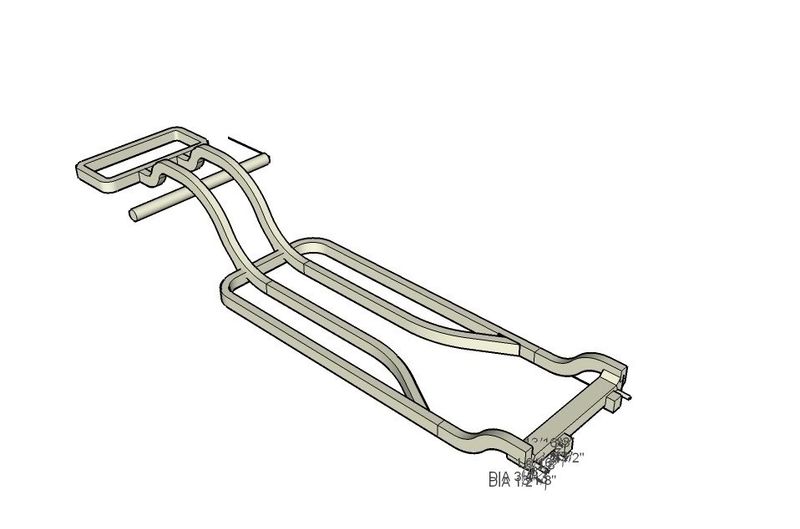

When you need to get something mandrel bent, but you're not the one bending, how do you figure out all the bends? I'm sure there is some kind of math involved, but is it an equation JUST for that, or a few steps to getting it or what?

bdroppeddak

+1y

i dont understand.... you just figure lengths and angles...... autoweld chassis has a diagragm that you just list all your measurements on for them.....

CC

creative concepts

+1y

i think he's asking.. if you were to make a driveshaft loop that is 6" in the middle, 14" tall, how would you know how much material is needed..

G

granth

+1y

I have a frame design I did up for my truck based on some measurements a buddy gave me for the front suspension, and I just have to do the rails and all that jazz. Once I figure the front suspension, and how high the crossmember will end up I want to have my rails bent so that they run up over the crossmember, set on it, and run back down to the ground. I have a basic idea of how I want it all to look, but not sure what to tell someone who is doing the bending.

for example, where it goes over the rear end, it's got two different bends in it, both different from one another. How do I go about telling someone what those bends need to be? Is it a matter of telling them that I need the bend to start at this point, go this high, and end at this point? I will go look at the autoweld chassis ordering form.

Thanks guys.

for example, where it goes over the rear end, it's got two different bends in it, both different from one another. How do I go about telling someone what those bends need to be? Is it a matter of telling them that I need the bend to start at this point, go this high, and end at this point? I will go look at the autoweld chassis ordering form.

Thanks guys.

B

BigDumbOx

+1y

not to highjack your thread, but what program do you use to make a drawing like that of your frame? some form of CAD program I presume? but which one specifically?

Ox

Ox

G

granth

+1y

google's sketchup. its free at first, but you can buy it for relatively cheap. its alot more simplistic than most 3d programs IMO. pretty cool to work with. it can get as accurate or as sloppy as you want.

mindlissmetalfab

+1y

dimension the centerline radius of the bends and all the heights of the flat sections in relation to a zero point like the bottom of the long section under the cab. Dimension the overall lengths from one end of the rail, as well as the bend locations (center of the radius) and give the heights of the bend locations and the angles of your rails.

G

granth

+1y

I think the autoweld chassis forms will help me. I just need to redo everything since I know now what to measure.

no1lowr

+1y

how about take your google sketch up and turn it to a side view, then jsut draw a schematic side view with the location of and distance between each bend, and state the degree of the bend at the point. pretty simple if you ask me, any mandrel bender can get the idea from your measurements and schematic.

Related Discussions in Air Ride Suspensions

Thread

Posts

Last Post