LAZER CUT OR WATER JET???

pimptruckman92

+1y

I was curious about lazer cut parts and the benefits of a lazer table, my last job had a water jet and I know some of the benefits. just wanted to spark conversation and see what every one prefers and their knowledge of each piece of equipment. do the lazers cut parts faster? anyway, WHAT IF YOU were going to purchase one of the two, which would you choose and why?

L

laynwindows

+1y

if i had the money i would buy a laser, they're more precise, cant cut as thick as a water jet, but i dont use anything that thick anyway...

but not only do i not have the money or space for a laser, my buddy runs a laser in a machine shop, and i get it all free of charge, so im not really doin too bad

but not only do i not have the money or space for a laser, my buddy runs a laser in a machine shop, and i get it all free of charge, so im not really doin too bad

pimptruckman92

+1y

thats the way to do it. how much did his actually run (ballpark $)? my former employer had a FlowJet it ran about $200-250,000 i think and it was able to cut about 18" thick steel. and you make a good point about not needing thickness.

ahab

+1y

I have parts lazer and water jet cut. From what I understand it is more expensive to run a lazer machine but it is faster if you have large runs of parts. The other difference is that the edges of the cut from a lazer will be hard where waterjet cuts dont have any effect on the metal. IE if you need to reem a hole out thats been lazer cut it will ruin your drill bits. This is just my limited experance with the two.

jeebus @ mmw

+1y

Water jet all the way. Not sure where you got your info from layinwindows, but a lazer is not more precise than a water jet.

Try to cut some intricate lettering in some aluminum, or steel with a lazer... then watch it look 10x nicer with a water jet.

Lazer machines are a faster, and can whip out big batches with the quickness, but to be honest, I can get my water jet table to run damn near as quick.

The only think i dont like about the waterjet is the noise.

Taylor

Try to cut some intricate lettering in some aluminum, or steel with a lazer... then watch it look 10x nicer with a water jet.

Lazer machines are a faster, and can whip out big batches with the quickness, but to be honest, I can get my water jet table to run damn near as quick.

The only think i dont like about the waterjet is the noise.

Taylor

gravity5

+1y

Water all the way, no heat affected zones, no warping, and you can cut so many more materials with water. We do custom cut glass all the time here at work, and you can do any type of wood, foams, plastics....Mirror, try cutting mirror with a laser.

guiltybydesign

+1y

Taylor... im hurt you would say such mean things about my fancy lil machine!

They both have their benefits and downfalls. The waterjet will cut thicker material and other materials than metal. My lazer is limited to 3/8'' alum and 1'' mild steel. Its also a $1,000,000 machine after delivery and setup. A lazer will generally cut faster than a water jet and it IS as precise. You run nitrogen through the lazer head and it keeps the heat down and does away with any work hardening of the edge. Water jets will cause the edge of the part to flash rust and on parts where you cant get a tool in there to sand it off it could cause a problem down the life of the part. Some machines will still bevel the edge of a thick part, advances in technology have almost eliminated this problem tho. Cost wise tho water jets are way cheaper and you arent limited to metals. It just depends on what you have to spend and what you want the machine to do.

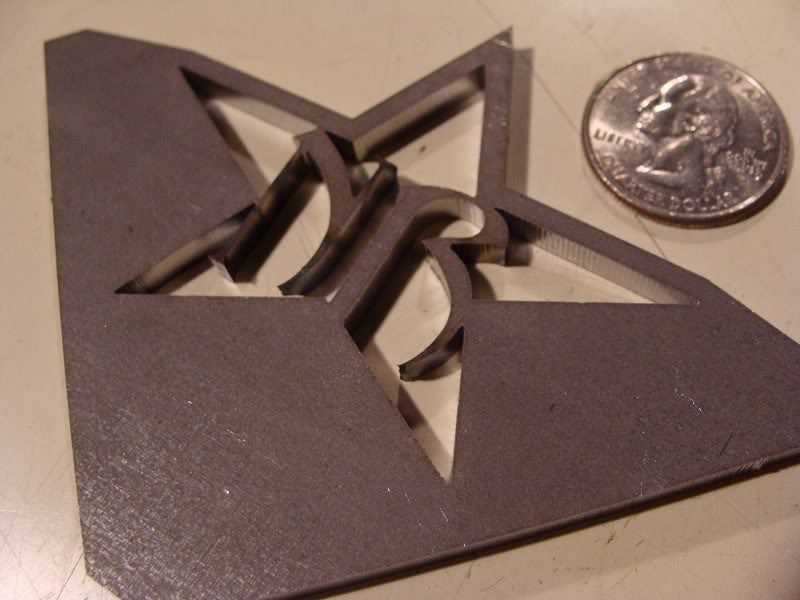

Heres a piece i cut 2 days ago.

If that aint precise i dont know what is.

They both have their benefits and downfalls. The waterjet will cut thicker material and other materials than metal. My lazer is limited to 3/8'' alum and 1'' mild steel. Its also a $1,000,000 machine after delivery and setup. A lazer will generally cut faster than a water jet and it IS as precise. You run nitrogen through the lazer head and it keeps the heat down and does away with any work hardening of the edge. Water jets will cause the edge of the part to flash rust and on parts where you cant get a tool in there to sand it off it could cause a problem down the life of the part. Some machines will still bevel the edge of a thick part, advances in technology have almost eliminated this problem tho. Cost wise tho water jets are way cheaper and you arent limited to metals. It just depends on what you have to spend and what you want the machine to do.

Heres a piece i cut 2 days ago.

If that aint precise i dont know what is.

jeebus @ mmw

+1y

bah, i dont agree haha, its all about personal preference i guess... ive just had poor results with lazer machines.

I worked at a shop years ago that ran a lazer table, with a nitrogen cooled head and we consistantly had issues with cutting anything in aluminum with any sort of intricacy in material less than .125" thick, it just blew back through the part it seemed like. I remember them having mfg reps and service techs look at it, and it just never got any better. Even still to this day ive never seen any lazer that can cut intricate small stuff in aluminum... even as small as a .125 hole in a .125 thick part.

It is really all preference tho, either machine is completely fascinating to me really. I would love to have the speed of a lazer table in the versatility of a water jet table, that would be damn damn nice!

I worked at a shop years ago that ran a lazer table, with a nitrogen cooled head and we consistantly had issues with cutting anything in aluminum with any sort of intricacy in material less than .125" thick, it just blew back through the part it seemed like. I remember them having mfg reps and service techs look at it, and it just never got any better. Even still to this day ive never seen any lazer that can cut intricate small stuff in aluminum... even as small as a .125 hole in a .125 thick part.

It is really all preference tho, either machine is completely fascinating to me really. I would love to have the speed of a lazer table in the versatility of a water jet table, that would be damn damn nice!

guiltybydesign

+1y

1/4'' aluminum. Its tricky but can be done with a quality machine. How many years back was it when you messed with one?

mindlissmetalfab

+1y

It all depends how the machines are set up. I use both and RARELY send anything to the water jet because it is set up for thick materials without being horribly slow. Its all going to depend on what you want out of your final product, and what you want to spend on the machine itself.

For most custom applications, you cant beat the speed and cut quality of a laser IMO.

For most custom applications, you cant beat the speed and cut quality of a laser IMO.

Related Discussions in Tools

Thread

Posts

Last Post