M

Stock Carb Mods Performance

N

ninjarider

+1y

New carb question. I'm the 2nd owner of a 86 2L cab+ I inherited. Truck has no top end power so I rebuilt the stock carb and it's a little better mainly at idle. This weekend I took it off and started looking at it up close. I noticed the secondary valve didn't seem to open very much. The more I looked the more I became convinced that the linkages for the secondary controls appeared as though with a little modification I might be able to convert it to function in a direct mechanical fashion, but before I go modding my linkages I was wondering what some of you guys might think. Also, if any of you who have converted to Holley's or Weber's still have your old stock maybe we can work out an arrangement for me to get the parts off of one of yours to test. I seriously doubt you will convert back to stock based on what I've read from threads here and other forums. Noob here I've got pics to explain what I want to mod and test.

Post was last edited on Apr 05, 2016 12:06. Edited 1

time.

N

ninjarider

+1y

Stock linkage setup.

N

ninjarider

+1y

This hook shaped linkage with the spring is what I think needs modding.

N

ninjarider

+1y

If the hook portion was cut off and the curved portion on the underside of the spring eyelet was filed down a bit and reinstalled above the piece indicated by the yellow sleeve, then the secondary valve will begin to open as the primary is being operated.

N

ninjarider

+1y

As it is in stock configuration the primary has to move to nearly half throttle before the hook portion begins to come into contact with the lapped metal portion of the secondary just below where the vacuum diaphram attaches.

N

ninjarider

+1y

I've found a modification for those who don't have a weber 32/36 or the Holley 5200 to install on their truck. I have been trying to diagnose a problem with my 86 b2k ext cab for a while now. The truck just didn't have any power between 45-60 mph. After I had to replace my radiator a couple months back I installed a tach so I would know what kind of rpm's I was running. For me 45-60 mph = 2000-2400 rpm. I don't know if others are getting the same results as me so I will post what I have done to try and ascertain where and why I was having power issues in the range I mentioned and what I've done to mitigate it. I realize these trucks don't make a lot of power to begin with but I was trying to figure out why it wouldn't pull itself up some of the smaller hills in the area I live outside of Atlanta in fifth gear. Seemed like I was always having to down shift, but it was mainly in the driving range I've already mentioned. I'm running the OEM carb on my truck and just don't have the cash for a weber kit.

I read on hear in a thread about the catalytic converter being plugged causing a power issue, so I checked mine and sure thing it had failed and was clogged. Gutted it (the first one attached to the manifold) was some improvement but it didn't completely solve the issue. Few weeks later I checked the rear cat and it too had failed so it was gutted. Still had the lack of power. The thing which kept pestering me in my mind was I would have the pedal floored and it just wouldn't give hardly any extra umph. I began suspecting the possibility the vacuum secondary wasn't opening giving me that extra little bit of power, but I haven't been able to find a method for bench testing it for proper operation. Since my carb is 30 yrs old I was pretty certain it wasn't working and I couldn't find a replacement diaphragm for it so I started thinking outside the box.

I came across a thread in a RX7 forum about some mods done to the original Nikki carbs and it kickstarted the creative juices flowing in my brain.

I read on hear in a thread about the catalytic converter being plugged causing a power issue, so I checked mine and sure thing it had failed and was clogged. Gutted it (the first one attached to the manifold) was some improvement but it didn't completely solve the issue. Few weeks later I checked the rear cat and it too had failed so it was gutted. Still had the lack of power. The thing which kept pestering me in my mind was I would have the pedal floored and it just wouldn't give hardly any extra umph. I began suspecting the possibility the vacuum secondary wasn't opening giving me that extra little bit of power, but I haven't been able to find a method for bench testing it for proper operation. Since my carb is 30 yrs old I was pretty certain it wasn't working and I couldn't find a replacement diaphragm for it so I started thinking outside the box.

I came across a thread in a RX7 forum about some mods done to the original Nikki carbs and it kickstarted the creative juices flowing in my brain.

Post was last edited on May 09, 2017 02:48. Edited 1

time.

N

ninjarider

+1y

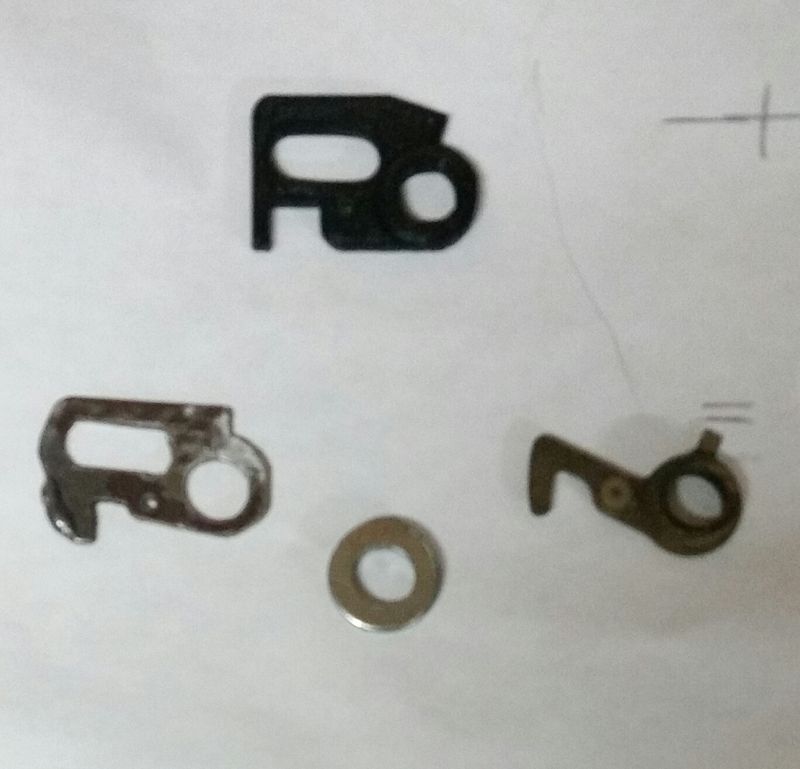

I took the hook piece of linkage in the photo above and traced it out and made a modification to it. I then traced that out onto a scrape piece of metal and went to hacking and filing. This is what I came up with.

N

ninjarider

+1y

The main hole is approximately 1/2 in in diameter (piece on the left) I took 2 flat washers and drilled them 1/2in also. (The upper piece is a design I made and printed out on my boys 3D printer) I didn't use it though because I will need to modify it some and reprint for it to be a viable option. The piece on the right is the OEM linkage.

N

ninjarider

+1y

Here is how it fits on the throttle shaft.

N

ninjarider

+1y

It may be hard to see but I had to weld a couple of beads onto the outer edge of the linkage to give a slight cam effect. The bottom tang of the secondary linkage will require slight modification as well, but its fairly easy. It just needs to be opened up and adjusted to where the (cammed edge of the linkage which was fabricated) will actuate it when the primary linkage begins to engage.

This whole mod essentially converts the OEM vacuum actuated secondary into a mechanical secondary which will begin to open when the primary butterfly valve is close to being fully opened.

In my test ride since doing this mod I did notice an improvement in the mid range power band and it did nearly solve my issue of power loss between 45-60 mph (2000-2400 rpm). It's not a substantial power increase like adding NOS or boost, but at least I'm not having to downshift from 5th to 4th to get up the hills in my area. I do suspect unless I came tame my foot my mpg will go down a little.

This whole mod essentially converts the OEM vacuum actuated secondary into a mechanical secondary which will begin to open when the primary butterfly valve is close to being fully opened.

In my test ride since doing this mod I did notice an improvement in the mid range power band and it did nearly solve my issue of power loss between 45-60 mph (2000-2400 rpm). It's not a substantial power increase like adding NOS or boost, but at least I'm not having to downshift from 5th to 4th to get up the hills in my area. I do suspect unless I came tame my foot my mpg will go down a little.