R

pinion angle 2 piece driveshaft

R

roadrage41

+1y

First I'm aware there are a thousand threads on this, I've searched and read and read my brain hurts from trying to comprehend it.

My measurements are -5, -4, +1, +4 with the front operating angle being 1 degree do we need to make the yoke +2 to get it kosher?

My measurements are -5, -4, +1, +4 with the front operating angle being 1 degree do we need to make the yoke +2 to get it kosher?

lockone

+1y

What are the specs on your suspension? Lowered, Bags, Boddied, or lifted.

R

roadrage41

+1y

Static with spindles and springs and a flipped rear. Carrier hasn't been touched.

lockone

+1y

What is the year, make, and model of the truck?

You should have gotten a shim kit for the carrier bearing. This should solve the problem you are having.

You should have gotten a shim kit for the carrier bearing. This should solve the problem you are having.

R

roadrage41

+1y

87 Chevy R30, CCLB, its a non dually, but the rpo says it is....

also, we've pretty much made the flip kit at this point with a set of u-bolts i had made, and a set of 3.375 perches, we can rotate the axle to where ever it needs to go because none of the aftermarket flip kits i tried were the correct size.

this work?

build thread -

also, we've pretty much made the flip kit at this point with a set of u-bolts i had made, and a set of 3.375 perches, we can rotate the axle to where ever it needs to go because none of the aftermarket flip kits i tried were the correct size.

this work?

build thread -

gjf

+1y

Best way is to raise the trans so it is at -3, and make the first shaft at -3 as well so the first shaft is acting like an extension of the transmission. Don't worry about the second shaft unless it is over 4 degree work angle which you will not be. Then make the rear end at +3 which will be at the same angle as the trans. You should be about 1.5 work angles at each end of the second shaft. Once the first shaft matches the trans you don't need to worry about trying to cancel out angles. This does however pertain to bagged trucks that lay frame. The angles of the driveshafts on those trucks vary drastically!!! They have at least 12" of travel! I ran into the same thing a while back and there wasn't much help figuring this out. I had static drop with 22's. 3" spindle 1" drop springs and in the rear a hanger kit with reached springs.

R

roadrage41

+1y

Read another post on an x frame forum - if the transmission is down 5 then the yoke should be up 5 and then you make the operating angles cancel each other out through shims on the carrier and rear end. With 1 degree operating angle being ideal, and 3 degrees being the Max. Sound about right?

pro53

+1y

I have a 98 chevy 454 dually, bagged dropped spindles, 22" semis, lays frame, 4 link in back. Vibrates at anything over 55 miles an hr, when I had mufflers put on it , you can tell. who did it did not set correct pinion angle. The rearend is ponting down to much. Who ever bagged it didnt touch the carrier bearing eith, no shims or anything. I was told to set the rearend at 0 deg. Is that corrrect? Will measure the tailshaft deg. and carrier bearing. I seen the post above. Just double checking to see the correct way.

dzl1

+1y

Pro53, I recently bagged my 93 crew cab and I'm having the same issues. My rear end is pointing too far down. I'm also getting vibration I was told that if the degree is extreme like mine is and I'm assuming yours is as well, that the perches on the rear end can be cut off and re welded to the correct pinion angle.

Just wondering if anyone else can chime in on this as I'm sure we aren't the only ones to have come across this issue.

DZL1.

Just wondering if anyone else can chime in on this as I'm sure we aren't the only ones to have come across this issue.

DZL1.

T

tutt

+1y

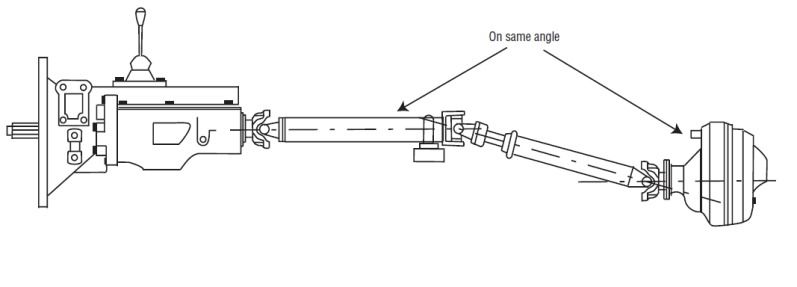

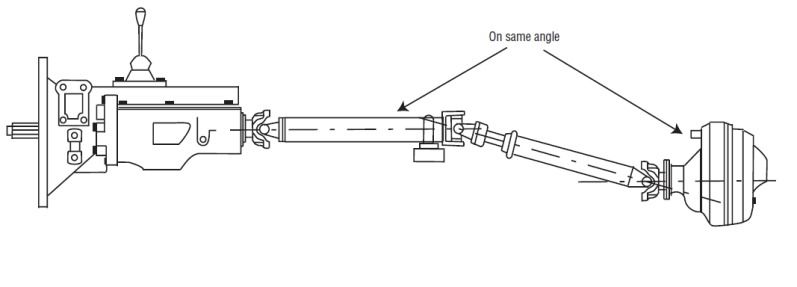

hopefully the below picture helps. it doesn't matter what the angle of the trans is as long as the rear end matches it. The important part is that the front drive shaft is perfectly inline with the trans. When you do this it's like the first drive shaft isn't even there and normal drive shaft geometry applies. To get the first drive shaft lined up you can shim the trans mount and the carrier bearing up or down.

Related Discussions in Dually Suspension

Thread

Posts

Last Post

Michigan Metal Works A-Arm group buy 88-98 Chevy/GMC 1500 to 3500 and dually's

S

last post by

Strokersace +1y

8

8

S

last post by

Strokersace +1y