PHANTOM GRILLE INSTALLED!!!

![90-b22dawg [andrew]'s avatar](https://static.streetsource.com/userphotos/2014/328/16283/s.jpg)

90-b22dawg [andrew]

+1y

ok so like title says i need some help, i understand that the headlights have to be recessed to install a phantom grille, does anyone have any tips to doing this or maybe some pictures to show how its done, also how far do the lights need to be recessed and what materials are needed as far as metal? any help will be greatly appreciated

Post was last edited on Dec 16, 2008 12:25. Edited 1

time.

aaron_dwarnock90mazda

+1y

i have seen some ppl just shave down the back side of the phontom to clear the lights. or like mine they just threw a set of fog lights in behind it. imo that way sucks cause at night you cant see crap and they move around to much.

![90-b22dawg [andrew]'s avatar](https://static.streetsource.com/userphotos/2014/328/16283/s.jpg)

90-b22dawg [andrew]

+1y

i dry fitted the phantom and i don't think there is a way to shave the back of the billet without going all the way through it and i don't want to do that anyways..... lights hold the grille about 1.75 inches out from sitting in correct spot...

aaron_dwarnock90mazda

+1y

i would like to see how some one sunk the lights in my self. i dont know if you could kinda do it just like a body drop. lol just cut a square around the light and sink it back about 2 inches. and then just box around it like that or not. but thats just my 2cents. lol good luck.

![90-b22dawg [andrew]'s avatar](https://static.streetsource.com/userphotos/2014/328/16283/s.jpg)

90-b22dawg [andrew]

+1y

dunno how to do it, thats why i want pictures of how its done, so that i can get some help doing it

A

all22s

+1y

why not just take pics of your install so he can see what was done?

K

kickinwing

+1y

I will have to see if I can get pics of my lights, I have the phantom on my new truck, and everything was done when I bought it so I don't know how they did it.

![90-b22dawg [andrew]'s avatar](https://static.streetsource.com/userphotos/2014/328/16283/s.jpg)

90-b22dawg [andrew]

+1y

because his install doesn't use stock head lights.... the previous owner just threw some fog lights in there....

elbine69

+1y

Just need to make the hole behind the light bigger. No extra materials needed, goes right back in like stock.

oo7bob

+1y

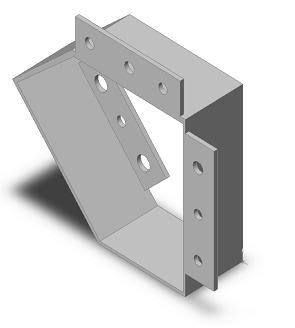

thats a better answer than mine. but, if you want to move the whole assembly back, so it still functions the same, you cut out around everything to do with the light

like this

make a cardboard template to move it back 2" with ears on both sides

you can use 16 gage from a hardware store and bend it with a vise so the one side will attach to the core support, and the other side to the piece you cut out

eg.

if you have a welder, plug weld it in, if not, you could use sheet metal screws.

dont need too many tools for this, a vise, sheet metal cutters, some cardboard.

anyway, thats how i'm gonna do mine.

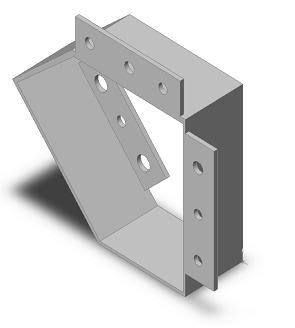

like this

make a cardboard template to move it back 2" with ears on both sides

you can use 16 gage from a hardware store and bend it with a vise so the one side will attach to the core support, and the other side to the piece you cut out

eg.

if you have a welder, plug weld it in, if not, you could use sheet metal screws.

dont need too many tools for this, a vise, sheet metal cutters, some cardboard.

anyway, thats how i'm gonna do mine.