DadandSonEyes - B2600i 4x4 REBUILD-Block Refinished

4365 views

9 replies

3 following

S

DadandSonEyes - B2600i 4x4 REBUILD-Block Refinished

D

dadandsoneyes

+1y

Hi Everyone, Just an UPDATE !!! Started this NEW THREAD ON THE NEWLY REFINISHED BLOCK AND ASSEMBLY PROCESS NOW FROM DadandSonEyes --

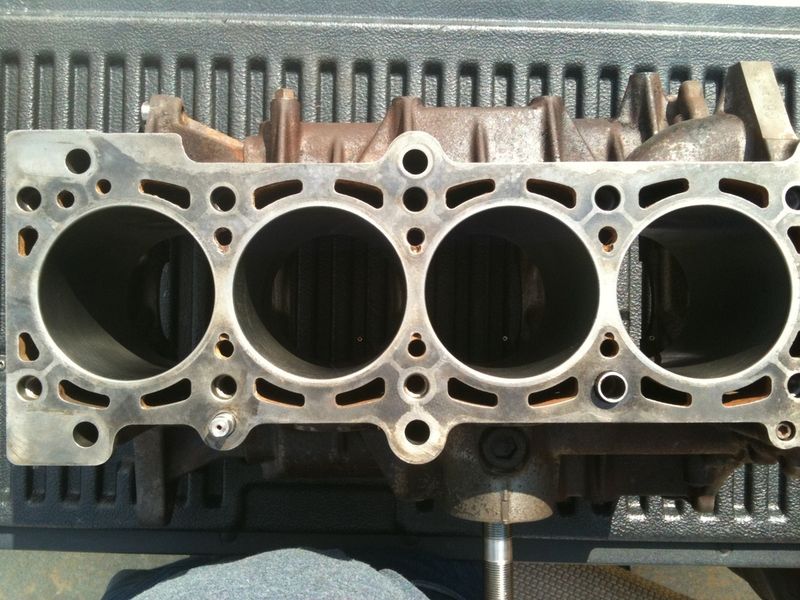

Below are the images of our refinished block, all sides and the Crank. On the L4 Block, we had the Machine Shop completely clean and bake it. The cylinders did NOT need Boring, they were Honed. The Crank Journals were cleaned. We sent the CRANK to another SHOP and had it turned and Polished and they Mic'd it and provided the CLEVITE PERFORMANCE Bearings that met the Crank size requirements. My son and I installed the CRANK and are awaiting the Piston Rings such that, we can install the Pistons sometime this coming weekend(between working all week and traveling on my day job, only the weekend affords a little time to do the Engine REBUILD).

D

dadandsoneyes

+1y

D

dadandsoneyes

+1y

All in ALL, SO FAR, it is turning out VERY WELL. We have several brand new PARTS coming in. When done, everything will be brand new, mostly. New Crank and Rod Bearings(CLEVITE ONLY), NEW Rings(Sealed POWER-Iron-Standard size), ALL Gaskets are (FEL PRO ONLY), ALL NEW GEARS AND Timing and BALANCE CHAIN from SA-GEAR, New Engine Ignition Coil, New Platinum Plugs, New Radiator, New A/C Condenser radiator, NEW Belts, REBUILT HEAD, NEW MAIN CRANK BOLT, NEW KEY, New Power Steeing Pump Pulley(NEED TO FIND THIS PART- DEALER WANTS $96.00 for it, rediculous )

D

dadandsoneyes

+1y

I forgot to take a picture of the Crank installed, but we did install the crank and followed the procedures, utilizing the Clevite RED GREASE and torque procedures. Final Torque was at 62 lb-ft. Book called for 61 to 65 on the Torque specifications. crank turns smoothly and didn't find any play laterally (from front to rear- all brand new CLEVITE BEARINGS) Smooth fit, very nice thus far.

------ DadandSonEyes ( FATHER / SON PROJECT - SON'S FIRST vehicle )

------ DadandSonEyes ( FATHER / SON PROJECT - SON'S FIRST vehicle )

D

dadandsoneyes

+1y

Oh, I forgot to mention.....we also found a full turn key F1 Performance Clutch ( full slip/friction disc) online on Ebay, was retail of $406, we got for $156.00 from GRIPFORCE,Higher Performance than STOCK and spec's matched for OEM REQUIREMENTs. -- more to come, we'll keep you all posted. Lots of work left to do once we get our gears in. That will take another WEEK. -- DadandSonEyes

axel breaker earl

+1y

Looking good man!

You can skip over to Mazdatrucking.com and see quite a few more pictures in several of my threads there on the B2600i engines I have worked on.

I finally buttoned up the bottom on the one I'm building now.....I have too many irons in the fire right now.....re-roofing my house, several work jobs going on now, and some surgical procedure next week........so my schedule is kinda tight right now!

You can skip over to Mazdatrucking.com and see quite a few more pictures in several of my threads there on the B2600i engines I have worked on.

I finally buttoned up the bottom on the one I'm building now.....I have too many irons in the fire right now.....re-roofing my house, several work jobs going on now, and some surgical procedure next week........so my schedule is kinda tight right now!

D

dadandsoneyes

+1y

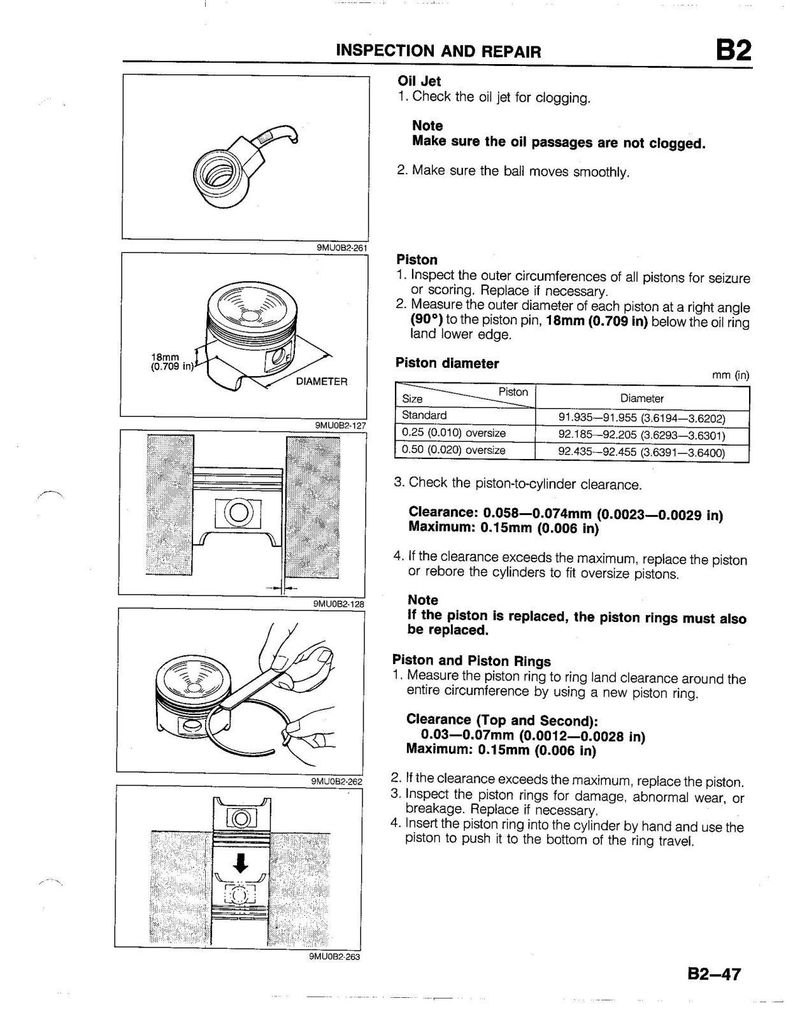

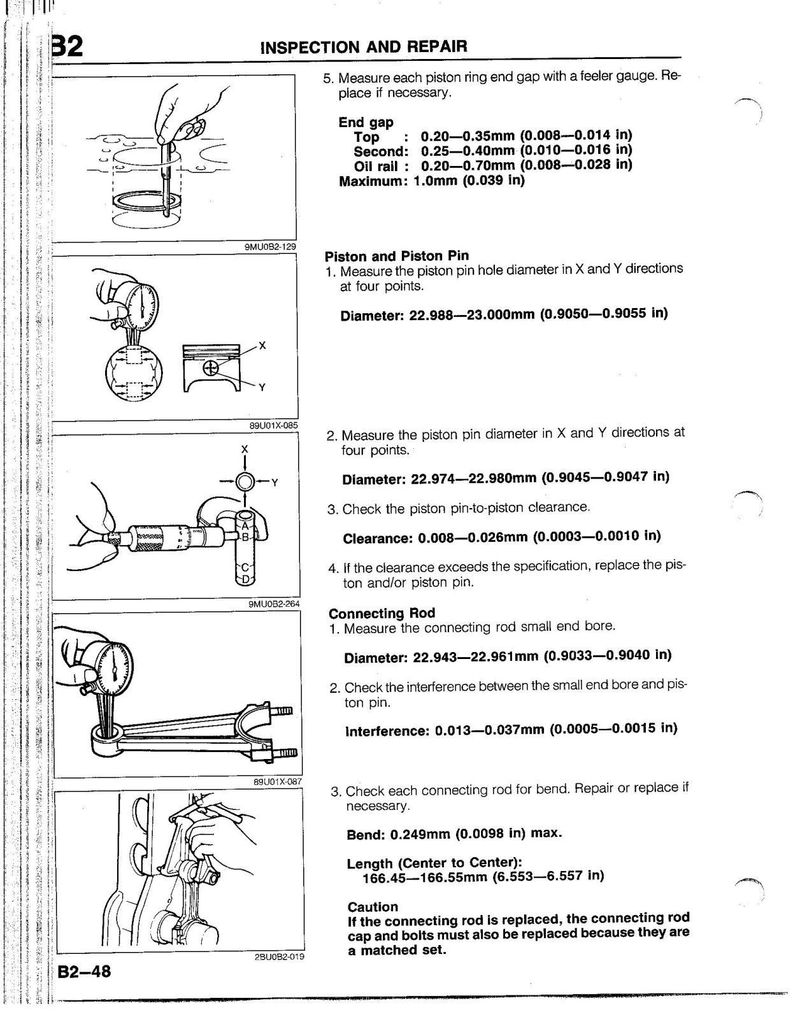

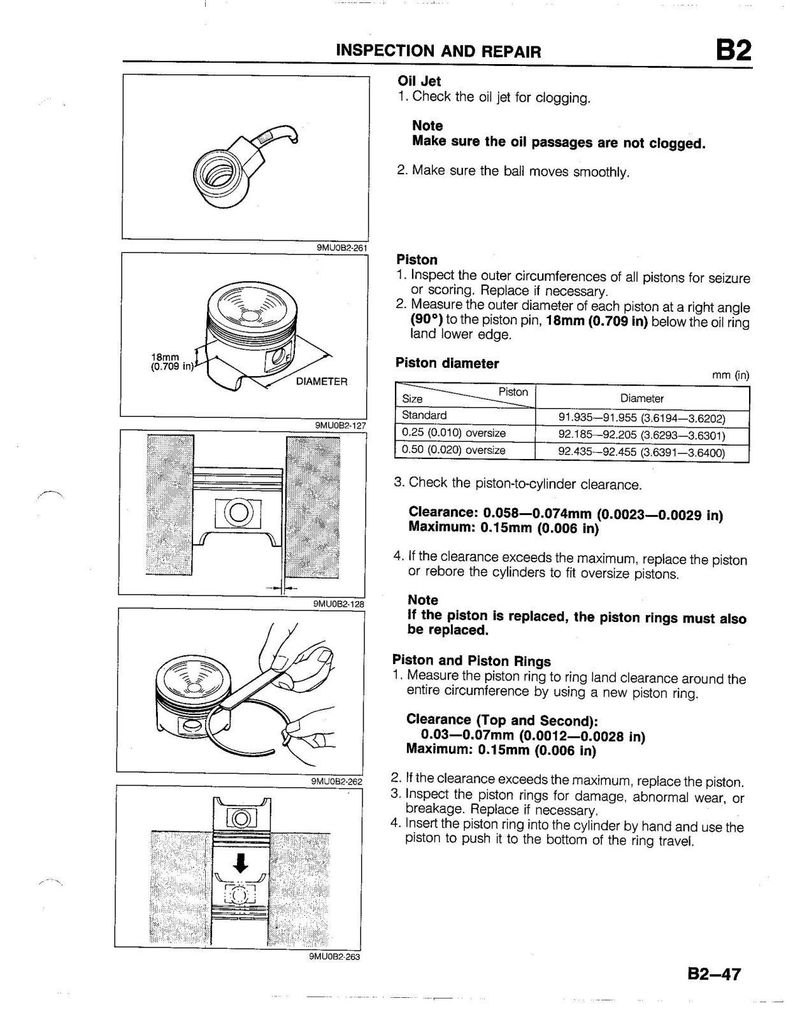

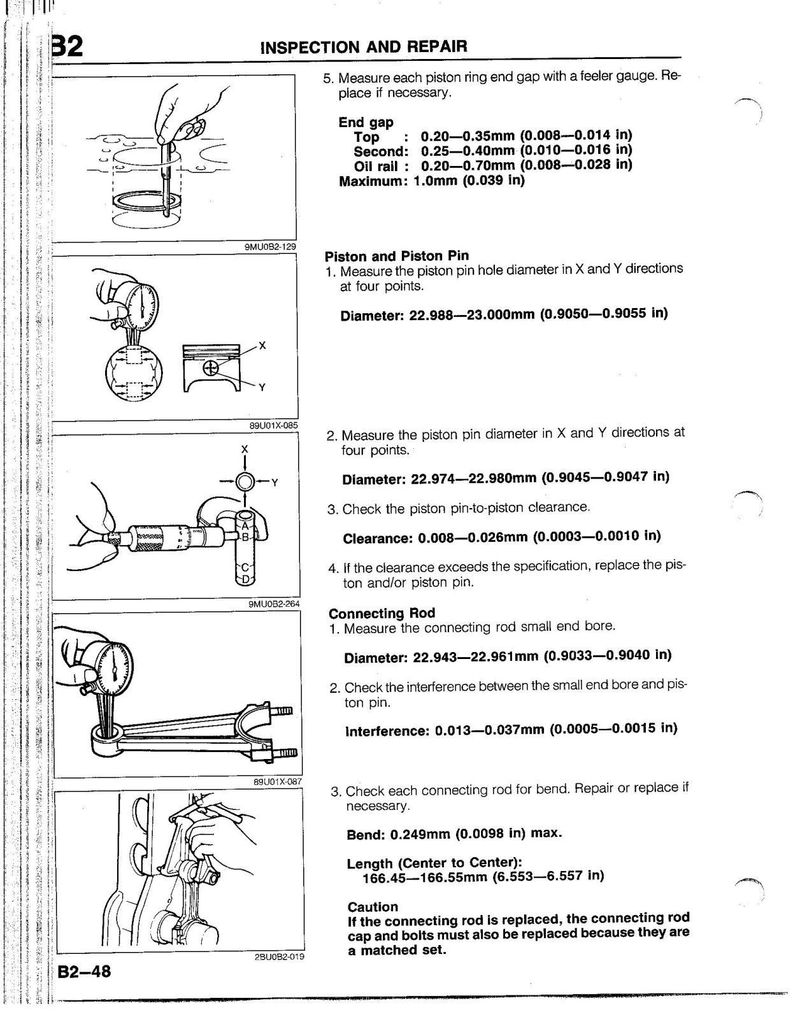

Ran into huge issue. Got the E510x sealed power

Standard rings. Put rings on. When putting pistons into cylinders. Goes

In as expected tapping with wood handle

And ring compressor with oil. But when top of piston ring is going into

Cylinder, it is extremely tight. Goes in much harder. Then we put bearings on inner two pistons. Takes a Paul Bunion amount of strength to turn crank. Almost impossible with big breaker bar on main crank bolt! Removed pistons. Checked rings again. Seem all ok. Repeated. Same issue. Rings were

Ordered as standard size. Doesn't make sense. Help

Standard rings. Put rings on. When putting pistons into cylinders. Goes

In as expected tapping with wood handle

And ring compressor with oil. But when top of piston ring is going into

Cylinder, it is extremely tight. Goes in much harder. Then we put bearings on inner two pistons. Takes a Paul Bunion amount of strength to turn crank. Almost impossible with big breaker bar on main crank bolt! Removed pistons. Checked rings again. Seem all ok. Repeated. Same issue. Rings were

Ordered as standard size. Doesn't make sense. Help

axel breaker earl

+1y

Did you install the rings (one by one) into the cylinder, square it up in the cylinder by using a piston (with no rings on it) upside down, and then check the end gap on the ring with a set of feeler gauges to see where your end gap is at?

If not, you need to do this! If they packaged your rings wrong, you may not have any gap (your supposed to have between .008" to .016" on the two upper compression rings.

If they are forced into the cylinders, they can break and bind up in the piston grooves, and/or scratch a groove into the cylinder walls when you try and spin the crank over.

Something is definitely NOT RIGHT if it is too hard to rotate!

Also, when you installed the crank, did it rotate easily without any rods connected yet?

If not, you need to do this! If they packaged your rings wrong, you may not have any gap (your supposed to have between .008" to .016" on the two upper compression rings.

If they are forced into the cylinders, they can break and bind up in the piston grooves, and/or scratch a groove into the cylinder walls when you try and spin the crank over.

Something is definitely NOT RIGHT if it is too hard to rotate!

Also, when you installed the crank, did it rotate easily without any rods connected yet?

D

dadandsoneyes

+1y

Thanks. Found the issue. I had the rings (grove 1 and 2 reversed). Directions were not clear. Fixed. All went in as expected. Thanks very much. Yeas, I did check the gap. They all fit properly now.

J

jenko

+1y

thank the devil you checked!

Looking good.

Though the CAPITALS makes IT hard TO READ the POSTs.

Looking good.

Though the CAPITALS makes IT hard TO READ the POSTs.