Street Source is shutting down April 30th, 2026. Read the announcement

tubular frame mounts for 4 link... how do you make them.

789 views

13 replies

11 following

W

tubular frame mounts for 4 link... how do you make them.

M

maxpower98

+1y

Edited: 4/13/2008 8:43:42 AM by maxpower98

Edited: 4/13/2008 8:42:58 AM by maxpower98

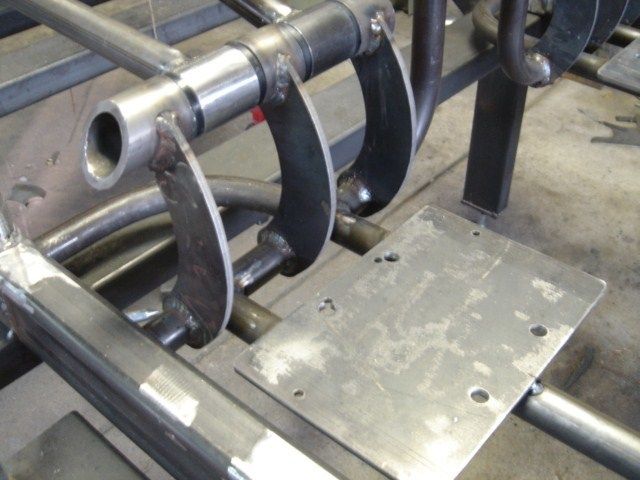

i have searched i know that there is a post somewhere where Barely legal fab explained how to make these tubular 4 link mounts. i cant find it though. how does everyone make these i am ordering metal soon so any help would be sweet. thanks.

Edited: 4/13/2008 8:42:58 AM by maxpower98

i have searched i know that there is a post somewhere where Barely legal fab explained how to make these tubular 4 link mounts. i cant find it though. how does everyone make these i am ordering metal soon so any help would be sweet. thanks.

jeebus @ mmw

+1y

Edited: 4/13/2008 8:56:20 AM by Chopped Mazda

i take some 2"OD-.250" wall DOM tube, cut it into however long you want each side of your 4-link mount to be.

Then i go get some 1.5"OD-.500 wall DOM and put it in the lathe, drill out the center hole to 9/16 , then skim the DOM skin off of it so it slides into the 2"-.250wall easliy. While the 1.5"OD is on the lathe, i will bevel a end, and then part off indivitual "washers", about .250-.375" thick. Make sure to bevel each one before you part it from the stick.

Toss those "washers" into the pieces of 2"OD-.250 wall that you cut origionally, and weld them in place. When your done welding you can put it in the lathe and face each piece to make them look perfectly machined smooth, or you can grind them to make the face smooth.... both ways work well.

Make sure to bevel each "washer" piece tho, because if you dont bevel it, you wont have anything to weld to.

hope all that made sence...

Taylor

i take some 2"OD-.250" wall DOM tube, cut it into however long you want each side of your 4-link mount to be.

Then i go get some 1.5"OD-.500 wall DOM and put it in the lathe, drill out the center hole to 9/16 , then skim the DOM skin off of it so it slides into the 2"-.250wall easliy. While the 1.5"OD is on the lathe, i will bevel a end, and then part off indivitual "washers", about .250-.375" thick. Make sure to bevel each one before you part it from the stick.

Toss those "washers" into the pieces of 2"OD-.250 wall that you cut origionally, and weld them in place. When your done welding you can put it in the lathe and face each piece to make them look perfectly machined smooth, or you can grind them to make the face smooth.... both ways work well.

Make sure to bevel each "washer" piece tho, because if you dont bevel it, you wont have anything to weld to.

hope all that made sence...

Taylor

rockstar-c10

+1y

I have no clue what you just said...

lucky_brew

+1y

how bout a pic or two to go with the thread ??? ???

bdroppeddak

+1y

for the average joe, get some tubing, make a cap for the end, drill a hole in it the size of your bolt for your 4 link, weld it on the end of the tubing, wala! just need one for the other side, then connect it to your frame somehow!

TwistedMinis

+1y

Originally posted by bdroppeddak

for the average joe, get some tubing, make a cap for the end, drill a hole in it the size of your bolt for your 4 link, weld it on the end of the tubing, wala! just need one for the other side, then connect it to your frame somehow!

Best way for anybody without a lathe.

I often use a hole saw to cut a piece out, then weld it in place and drill the hole out. I use 1/8" plate, or 3/16" sometimes.

for the average joe, get some tubing, make a cap for the end, drill a hole in it the size of your bolt for your 4 link, weld it on the end of the tubing, wala! just need one for the other side, then connect it to your frame somehow!

Best way for anybody without a lathe.

I often use a hole saw to cut a piece out, then weld it in place and drill the hole out. I use 1/8" plate, or 3/16" sometimes.

jeebus @ mmw

+1y

Originally posted by lucky_brew

how bout a pic or two to go with the thread ??? ???

how bout a pic or two to go with the thread ??? ???

rockstar-c10

+1y

I see said the blind man, now i understand.

bdroppeddak

+1y

oh yea, the hole saw is a sweet way to make caps, thats the way i do it since i never have heavy walled tubing like taylor... then i face them in the lathe

P

Pneufab

+1y

http://www.aa-mfg.com/pdshop/shop/item.asp?itemid=927

If you are using 1.75" tubing

Just drill a hole in the center and weld it on (or visa versa)

for $.20 it doesn't make sense to mess with a hole saw (although I have done it many a time)

t

If you are using 1.75" tubing

Just drill a hole in the center and weld it on (or visa versa)

for $.20 it doesn't make sense to mess with a hole saw (although I have done it many a time)

t

Related Discussions in Air Ride Suspensions

Thread

Posts

Last Post