Saturn Ion Hydro Build

artsar

+1y

so I'd be better off to make new lower mounting plates (where the strut bolts to the spindle) rather then cutting the stock ones off and having those welded on.

AON-4PumpedCL

+1y

---------------------------------------------Originally posted by artsarso I'd be better off to make new lower mounting plates (where the strut bolts to the spindle) rather then cutting the stock ones off and having those welded on.---------------------------------------------That would be my suggestions, but either way would work fine.

artsar

+1y

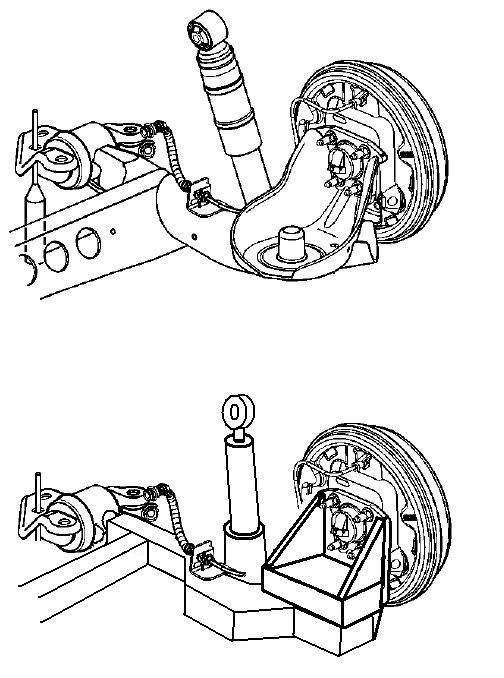

Small update. I ordered all the plates to get the front done from Mindliss Metal Fab. It was the best price and best quality out of the people I contacted... I'd suggest this business to anyone needing metal parts, and not only because they are CANADIAN. Also just looking for some advice for my rear end Idea. Top is Stock Bottom is my idea Basicly I will plate the upper shock mount so theres more material to take the load of the car and then build a new swing arm, just 2" longer. At the end where it mounts to the car I want to get an adjustable rod end (bushing) so I can align it and since the stock bushings are a different size then normal 4 link ones, I'll have to modify the bracket. As for the bottom of the cylinder. I planned to weld a 4 link bushing to it and then just bolt that to the swing arm. Does this look like it will work or does anyone have a better suggestion?

AON-OFFDAHOOK

+1y

Seems like a lot of work, but having that moved back (although 2" seems too much to me) seems to be benificial to make it lower so the axle isn't too far forward when dumped. I almost think I'd ditch the shocks and run a powerball on the center of that lower spring cup and go straight up with a hole saw through the upper spring cup (the upper part of the cylinder will pivot through the hole). Then space down the cylinder accordingly to where the cylinder bottoms out at the lowest point the wheels allow it to go so you get your maximum lift.

artsar

+1y

I'll have to take a look to see where the upper spring pocket is and see where it comes through into the car. I know that I have to stretch the axle though. The tire already hits the inner door, so its either stretch the arm or stretch the mounting plate. Its not the swing arm that hits the car its the tires, so moving the axle down won't help I don't think. Based on my mental geometry. I'll still have to look though. The only thing holding me back from going through the trunk floor is I just built a sub box for the car and I'd have to make a new one... hmmmm

k24 rd6

+1y

Do you have any pics with the suspnsion fully compressed to see how far forward the wheel moves?Instead of stretching the swing arm, what about just moving the hub/spindle up. This way it will still help with the wheel moving forward when compressing and have better bushing angles.

artsar

+1y

sorry for the delay, I just moved and I don't have internet at my house so I only get online when I visit friends. It might be a bit hard to tell, but it hits basicly right where the door meets the rear quarter.I figure once I can get a chance I will unbolt the rear swing arm and make one from wood to see if my mental geometry is right and it will also allow me to build a prototype cheap.

artsar

+1y

Small Update I found a local welder who is willing to help build the front cylinders for me. I also got my 2nd set of cylinders. My main question is with link ends, I have 3.5" of space between my brackets (for the link end) Its actually 3 9/16ths. Can I run a 3.5" or should I get one slightly bigger. Basicly how much play are you allowed?

AON-OFFDAHOOK

+1y

Having a little play isn't going to really hurt anything, although it gives the joint an opportunity to knock around creating some noise.

mindlissmetalfab

+1y

Hey Adam I never put 2 & 2 together that this was you. haha, You are on www.minitruckin.ca as well. I'm glad you liked the parts. I emailed you back on that other stuff today but if you managed to find someone local to do that welding for you thats cool. Let me know if you need anything else.