Rear Cylinder Location

artsar

+1y

Edited: 1/19/2010 1:36:43 PM by artsar

the only thing that comes to mind when drilling a hole in the floor is that the swing arm mount point will move away since it will swing away, but the cylinder will remain vertical. In my situation wouldn't both ends of the cylinder need a pivot, so the heim on one end and some pivot on the other? I was just thinking. I could probobly run it vertical with your new sleeved ball joint and a heim on the bottom and still run the cylinder on the back side of the axel. That should allow me to keep my hydro rack as is and run the cylinder vertical.

the only thing that comes to mind when drilling a hole in the floor is that the swing arm mount point will move away since it will swing away, but the cylinder will remain vertical. In my situation wouldn't both ends of the cylinder need a pivot, so the heim on one end and some pivot on the other? I was just thinking. I could probobly run it vertical with your new sleeved ball joint and a heim on the bottom and still run the cylinder on the back side of the axel. That should allow me to keep my hydro rack as is and run the cylinder vertical.

garagebuilt

+1y

i think you will be ok welding the uppermount to the frame. i welded the mount for my shocks to the frame where you are talking about. once its cleaned up it welds nice to the 1/4" plate. on my old setup i had the shock on the back of the swingarm like you are talking about. the welds on top are just tacks to hold it but the welds down the side came out good the pic is small but you could do something like this but i would gusset from the outside edge down to the bottom of the frame

garagebuilt

+1y

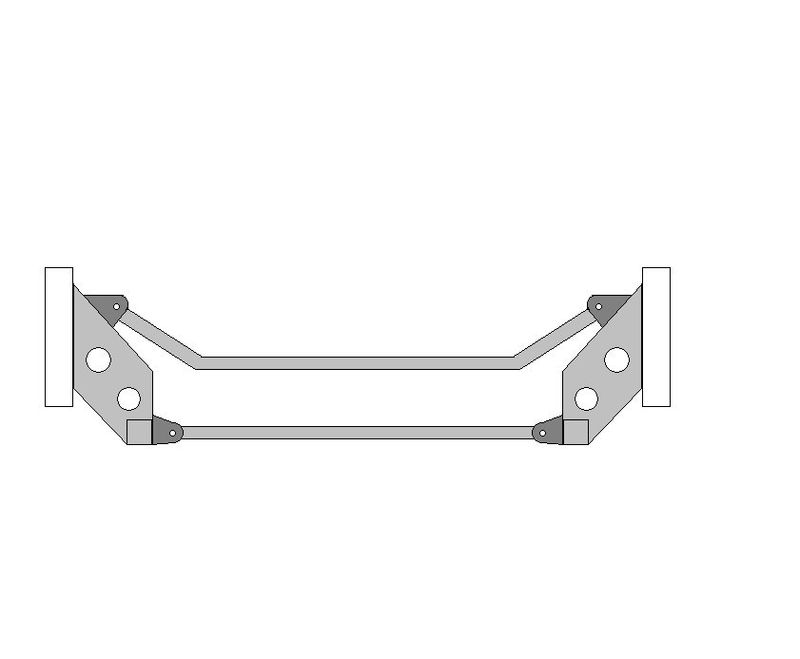

I would also suggest more gusseting on the cross bar. that was my issue. with the 2 link not having any side to side flex it twist the rear when i went through a dip at an angle it twisted. the wheel cambered in and it was ruined. here is my crazy idea for your set up. take what you have but remove the cross bar. then run 2 bars with heims from one side to another. the upper bar will need to be bent to fit around the spare tire tub. it will also need a locator to keep it centered. these bars will keep the wheel from cambering in. and you would be able to adjust the camber by adjusting the heims. patent pending this pic would be from the rear

artsar

+1y

So I was looking into the cylinder through the trunk idea and I thought about 2 different ways to position the cylinder. Since my car requires more articulation of the cylinder then most I figured that these two approachs might work. I also figured that you are right about the pump/battery rack. While it was 300 bucks, if the cylinders don't work then I still have nothing. I am better off just cutting my losses and continuing. The ruler would be the swing arm bar. In this set up the heim would be on a mount in the trunk and the bushing pivot would be attached to the swing arm. In this set up the desk top represents the trunk floor and the ruler still resembles the swing arm. Both require me to cut a hole in the floor. What method do you "gods of juice" suggest? In both set ups the cylinder will be in a bit of the swing arm be about 2". I don't feel safe modifying the actual subframe. Also I would not be using the bracket pictured. I would be getting a new one made that is similar but would work better in either set up. Question is, is it better to have the fitting in the car or outside? (I think i know the answer, but I figured I would ask.

garagebuilt

+1y

without having the arm bolted on the car its hard to tell what you will have room for. maybe something like the pic below. then mount the heim like i said before on the inside of the frame rail. i would say bolt the arm up and see if you can fit the cylinder on the inside of the frame without having it at too much of an angle. it would be nice to have the hubs and wheels on it too to see where it sits. are you trying to actually lay the rear out or just set it on the fenders? i would try not to cut the floor unless you have to

artsar

+1y

The only problem is that with the car still higher then I want the heim hits the floor and the cylinder is on an angel. I think when I get the swing arm squared up next week I am going to figure out the cylinder placement and cut a hole in the floor and get my last bracket to link the cylinder to the swing arm. Its not the way I wanted it, but I can either try and get the cylinder vertical or just keep messing up cylinders which after 1 set of replacement cylinders will be more then the rack cost me. For the Hydroholic guys... That new threaded upper pivoting mount. what kind of articulation does that get?

tre5

+1y

OK. I have been hesitant to post on this subject. It is too hard to figure out the best way to do it without actually being "hands on." But since there hasn't been the best answer yet I will chime in with what I think is the best answer. First off, don't mount the cylinder upside down. I did it on my Mazda and on the Tahoe. Both of them never seemed to ride as nice. Mac Pherson strut cars don't seem to ride as nice with the cylinders upside down either. I am not sure exactly why that is, but I will try to not mount them upside down anymore. That is one of the reasons we came up with our new top mount. It is part of what will be an alternative to how a mac strut car needs to be done.Second, here is my idea. Mount the cylinder at the bottom with the heim. Simple tabs off the new axle piece you had made. Where those tabs are will depend on the width of your frame rails. Now for the top mounts. Since you haven't posted a pic of the inside of the trunk I am saying this as if there is nothing in there and like Derek said already, you need to be more concerned with cylinder placement than your pump mount. I would make a bolt in crossmember, like a strut tower bar. Make some plates that bolt through the area where the frame rails are spot welded to the body. There should be 3 or more layers of metal there. You could also try to make plates on the bottom and sandwhich the rails. You could make a very simple crossmember/ strut tower bar out of tube, bent down and welded to the bolt in plates. Then put some tabs off of that to hold the sleeve with the bushing on it. Or you could get fancy with it and put our new upper pivot mounts into a boxed plate upper crossmember. Either way, the cylinders would be upright, come through the trunk floor, and would probably end up being towards the inside of the rails. It looks like you have the room for them between the rails and the spare tire well, but I can't tell. That is the best I can come up with for you. Unless... You go the easy way. Get 6" cylinders, throw that stock axle back in, weld up the top port in the cylinder, tap in a new side port, weld some tubing to the top of the cylinder and tap it to accept a heim, then bolt the heims where the stock shock bolted in, and double shear that lower shock mount.

artsar

+1y

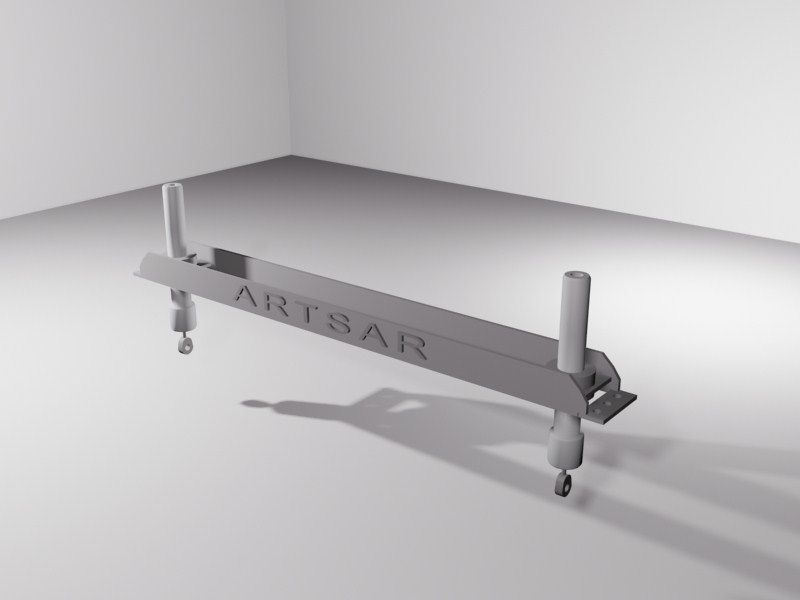

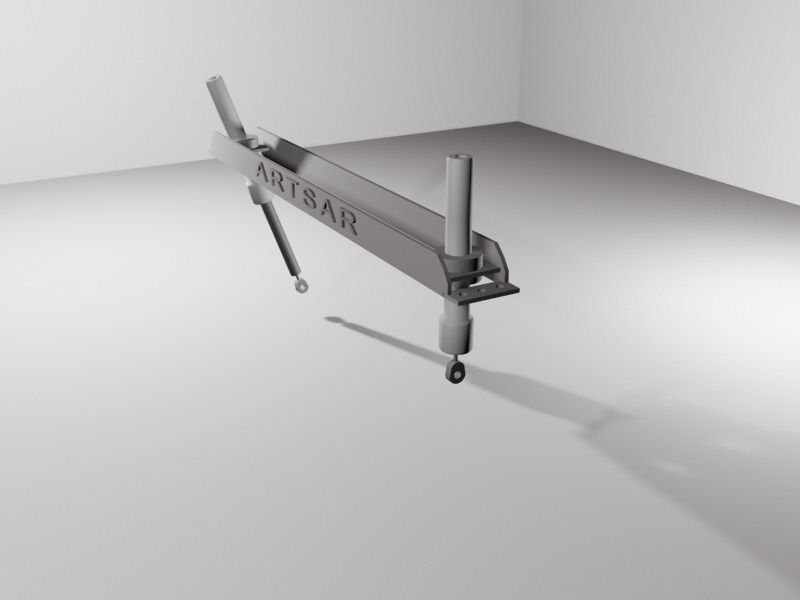

Thanks Jeremy After what Derek said I figured that I would do what I could with the cylinder and figure out a new pump rack after the cylinders were in. I also did a quick rendering and it turns out that the cylinder will not rotate that much though the movement. I was thinking of getting one of your new threaded sleeve joint dealies and cutting a hole between the spare tire well and the sub frame. I thought that maybe a bolt in doughnut welded to that threaded joint would work. I would run the heim pointed towards the ground and make a tab off of the swing arm that would allow the heim to be bolted to it. I like the idea of the strut bar in the trunk, so I could even weld your joints to that have that bolted in through the floor. I will do a rendering in my 3d program tomorrow and post it up to see what everyone thinks. My renderings are NOT to scale, just made to give a general idea.

tre5

+1y

^^^ sounds like we are on the same line. Good luck.

artsar

+1y

So I figure something like this. Again this is not 100% to scale, but I think it gives you the idea. Also any word on the diameter of your new threaded upper bearing dealies?

Related Discussions in Hydraulic Suspensions

Thread

Posts

Last Post

11

last post by

Darrickglods +1y

ASK THE EXPERTS! Hydroholics open forum on any hydraulic related questions you may have.

last post by

traemvincent +1y

8

8

last post by

traemvincent +1y