Square body Chevy build up by Tre5 Customs

14859 views

54 replies

32 following

Square body Chevy build up by Tre5 Customs

mjavy7

+1y

I like what I see so far :).

J

juicedwagon

+1y

that front frame section looks great! can't wait to see some more.

david lee

+1y

tre5 how is the airbag or hydraulic cylinder going to interact with your torsion bars? Whats the benefit to this design?

tre5

+1y

The hydraulic cylinder is going to push on the torsion bar where the key would normally be. Since the hydraulic cylinder is stationary in whatever position you adjust it to, the spring rate will be that of the torsion bar. I am using stock 4x4 Chevy torsion bars, so the ride should be very similar to stock. In the rear it is the same theory, but I am using aftermarket torsion bars commonly used in sprint cars. I had to do some research to come up with what I think will be the correct spring rate so I could order the correct torsion bar and fabricate the correct length arm to connect the bar to the axle. I've been designing the rear suspension all day today, so hopefully I'll get the final design soon and get them cut out and welded.

X

xgolferdude

+1y

Won't there be some deflection though? I mean I didnt think torsion bars were ment for this kinda travel? The more it lifts the stiffer it'll get and same for the drop.. I would've thought there would be only a small sweet spot for ride quality like this. However I'm very much a novice to a set up like this.. So I'm prolly wrong.. Could u shed some light on the Jeremy. Looks great so far!!

tre5

+1y

I am not using the torsion bar to get the adjustment, I am using the cylinder for the lift and drop. All the torsion bar does is provide the spring rate. The torsion bar will maintain it's spring rate no matter how much the cylinder is extended or collapsed. The weight of the vehicle maintains the same whether it is 2" off the ground or 10" off the ground, and that is what will be twisting the torsion bar.

-

Just think of a stock torsion bar setup in a 90's 4x4 Chevy truck, Nissan hardbody, mazda B series, ect... the torsion bar splines into the lower control arm then heads towards the rear of the vehicle. Somewhere under the cab there is a crossmember with a torsion bar key and adjuster. When you wanted to lower your hardbody back in the day you would loosen the bolt that adjusted your torsion bar key. As the bolt was loosened, the key would rotate, thus lowering your truck. Instead of adjusting a bolt, I will be rotating the key with the cylinder.

-

The truck will ride on the spring rate of the torsion bar, with the help of some nice shocks. So lets say I am cruising at 4.5" off the ground (where I set ride height) and I hit a bump... the cylinder will not move at all (because there are no accumulators), instead the torsion bar will twist. It's just like having a coil over setup with hydraulics... when you hit the same bump, with the same spring rate, the suspension will compress the same amount. The only difference is how the spring rate (the tension being pushed back against the weight of the vehicle by the spring) is transferred. On the coilover the loops are being pushed away from each other whereas the torsion bar is trying to untwist.

-

Just think of a stock torsion bar setup in a 90's 4x4 Chevy truck, Nissan hardbody, mazda B series, ect... the torsion bar splines into the lower control arm then heads towards the rear of the vehicle. Somewhere under the cab there is a crossmember with a torsion bar key and adjuster. When you wanted to lower your hardbody back in the day you would loosen the bolt that adjusted your torsion bar key. As the bolt was loosened, the key would rotate, thus lowering your truck. Instead of adjusting a bolt, I will be rotating the key with the cylinder.

-

The truck will ride on the spring rate of the torsion bar, with the help of some nice shocks. So lets say I am cruising at 4.5" off the ground (where I set ride height) and I hit a bump... the cylinder will not move at all (because there are no accumulators), instead the torsion bar will twist. It's just like having a coil over setup with hydraulics... when you hit the same bump, with the same spring rate, the suspension will compress the same amount. The only difference is how the spring rate (the tension being pushed back against the weight of the vehicle by the spring) is transferred. On the coilover the loops are being pushed away from each other whereas the torsion bar is trying to untwist.

D

dirtyd97

+1y

This is the same setup I had on my Nissan in the late 90s it worked and road fantastic. Great work keep it up

tre5

+1y

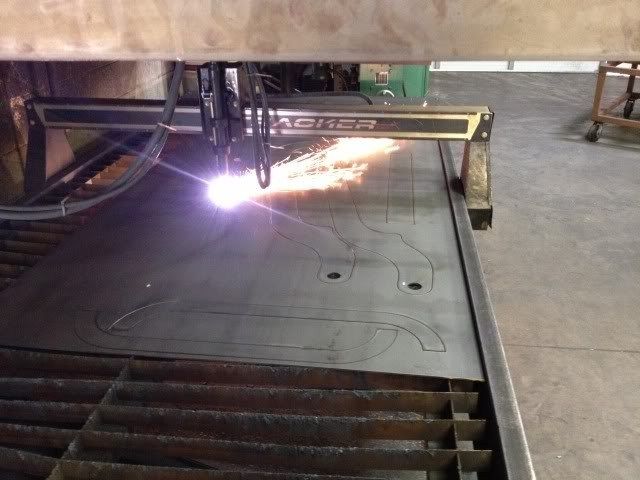

Cutting out the rear rails...

S

sleeve15

+1y

Any updates on this can't wait to see the frame complete.

DCNDED

+1y

looking forward to your updates!!! and thanks for taking the time to post them up !!!

--------------------------------------------

dirtyd97 said:

This is the same setup I had on my Nissan in the late 90s it worked and road fantastic. Great work keep it up

--------------------------------------------..small world...got your old truck in my shop right now, has been for a while now ...pm if you want to know more as to not jack this thread from a killer build!!

--------------------------------------------

dirtyd97 said:

This is the same setup I had on my Nissan in the late 90s it worked and road fantastic. Great work keep it up

--------------------------------------------..small world...got your old truck in my shop right now, has been for a while now ...pm if you want to know more as to not jack this thread from a killer build!!

Related Discussions in Build-Ups

Thread

Posts

Last Post

32

last post by

baha 2 mo

0

V

last post by

Vic 6 mo

168

last post by

truck action +1y