Pinion Angle

gjf

+1y

Is it generally better to have the pinion down rather than up? Or it doesn't matter?

lockone

+1y

We normally set the 3-5 degrees upward so that under loaded conditions it will be parallel or 0 degrees.

gjf

+1y

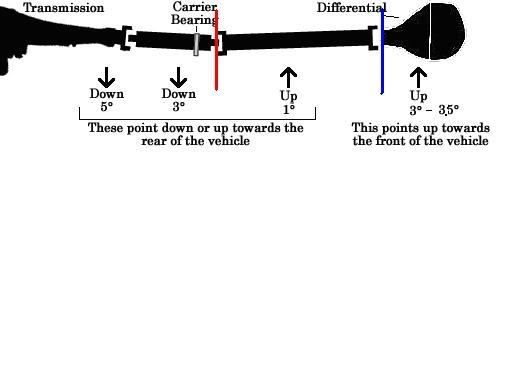

3-5 up meaning the yoke part is pointing upwards. But when you apply a load on the truck the rear end wants to tilt up even further. So how does the angle go to 0? I have 5 degree tilting down at the tranny 2.5-3 tilting down at the first driveshaft, 1 degree pointing up at the second drive shaft and 3.5 tilting up at the pinion.

H

huskerdually

+1y

I copied this from another site.

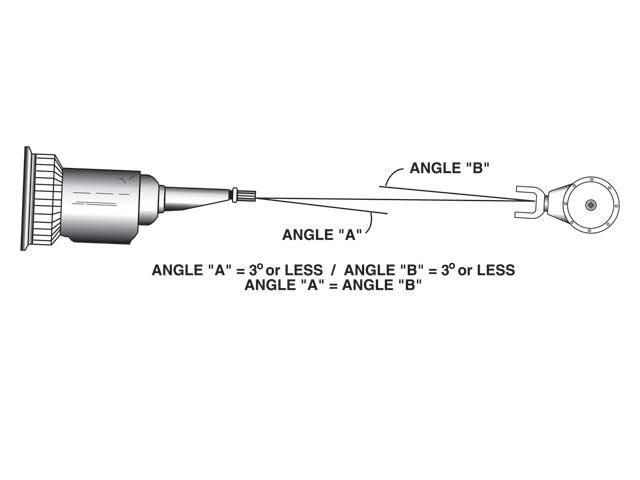

Angle setup for two-piece shafts is similar to the one-piece. All three working angles should add up to zero. The easiest way to do this is to mount the front shaft section so it has zero degrees through the joint at the transmission. The rear shaft may then be treated as if it were a single shaft. Sometimes this is not possible and all three angles must be juggled to arrive at zero.

Don't know if that helps you.

This is my knowledge and opinion...

The pointing the pinion down a few degrees more than what is needed comes from drag racing. With the extreme loads and axle wrap and such the theory is that the pinion angle is correct under load. I don't know if that is necessary in your application, even if you did manage to twist the pinion up under acceleration it would probably come back down once under way. You do not necessarily want the front driveshaft in a straight line from the tranny. If it is then the u-joints are always spinning the same and they will wear quicker. By adding a little angle at the front joint it helps the needles rotate in the joint therefore lubricating them better.

What is your vehicle and mods, might be able to help you out a little better.

Angle setup for two-piece shafts is similar to the one-piece. All three working angles should add up to zero. The easiest way to do this is to mount the front shaft section so it has zero degrees through the joint at the transmission. The rear shaft may then be treated as if it were a single shaft. Sometimes this is not possible and all three angles must be juggled to arrive at zero.

Don't know if that helps you.

This is my knowledge and opinion...

The pointing the pinion down a few degrees more than what is needed comes from drag racing. With the extreme loads and axle wrap and such the theory is that the pinion angle is correct under load. I don't know if that is necessary in your application, even if you did manage to twist the pinion up under acceleration it would probably come back down once under way. You do not necessarily want the front driveshaft in a straight line from the tranny. If it is then the u-joints are always spinning the same and they will wear quicker. By adding a little angle at the front joint it helps the needles rotate in the joint therefore lubricating them better.

What is your vehicle and mods, might be able to help you out a little better.

gjf

+1y

Thanks Husker!

I have a 99 3500 dually with a 4" total front drop using 3" spindles and 1" drop springs. The rear has a 6" drop using hangers and rear shackles running 3 leafs and the helper spring. Eagle Alloys running 225/75/16

I have a 99 3500 dually with a 4" total front drop using 3" spindles and 1" drop springs. The rear has a 6" drop using hangers and rear shackles running 3 leafs and the helper spring. Eagle Alloys running 225/75/16

H

huskerdually

+1y

What measurements do you have right now?

gjf

+1y

how i post a pic?

H

huskerdually

+1y

gjf

+1y

Thanks Husker!

H

huskerdually

+1y

If it was mine I would raise the carrier bearing enough that when you put an angle finder on the yoke it would measure 0 degrees(red line in my little illustration). The I would set the pinion at 4 degrees up(blue line). That would make all your angles equal one down.

Related Discussions in Dually Suspension

Thread

Posts

Last Post

Michigan Metal Works A-Arm group buy 88-98 Chevy/GMC 1500 to 3500 and dually's

S

last post by

Strokersace +1y

8

8

S

last post by

Strokersace +1y

2

B

last post by

bestlinemanever +1y