Valve are ticking

vieyra e p

+1y

Is there a way to get my b2000 to be quieter? The valves are ticking.

dan woodland

+1y

If I remember correctly your truck has mechanical lifters.

1. Replace the lifters OR

2. Replace the lifters and rocker arms with a set of HLA (hydraulic lifters) from a 2.2. Some guys have done this because they had access to a local bone yards with the equipment they needed.

When mine started ticking and would not go way after the engine warmed up I added that to my list of reasons to rebuild the entire engine (Also had massive oil leaks, blown head gasket, warped head etc..).

Make sure your engine oil is up to the proper level too.

Dan

1. Replace the lifters OR

2. Replace the lifters and rocker arms with a set of HLA (hydraulic lifters) from a 2.2. Some guys have done this because they had access to a local bone yards with the equipment they needed.

When mine started ticking and would not go way after the engine warmed up I added that to my list of reasons to rebuild the entire engine (Also had massive oil leaks, blown head gasket, warped head etc..).

Make sure your engine oil is up to the proper level too.

Dan

vieyra e p

+1y

Thanks dan I will look into getting some new HLA lifters.

axel breaker earl

+1y

If your truck is a 2nd gen B2000 (1986-1987) and it still has the original engine installed, then it has mechanical rocker arms.

Mechanical rocker arms are designed in such a way where you will need to periodically adjust the excess valve lash or "play" out of the valvetrain by adjusting the mechanical rocker arms.

All the B2200 engines (1987-1993) had hydraulic lash adjusters in the end of the rocker arms and they need no periodic adjustments.....but they do get worn and/or clogged with grit or debris and therefore start to tick.

Adjusting the mechanical rockers is a fairly easy job to do if you are mechanically inclined, if not, any auto repair shop can do this for you.

If they have never been adjusted........it's time!

I need to look in one of my 1986 or 1987 user manuals to see what the interval is for the mechanical valve adjustment.......I'll see if I can find the info and post it here.

The interval for adjusting the mechanical rocker arms (or valve lash adjustment) is every 15,000 miles according to the 1986 B2000 Owners Manual.

Mechanical rocker arms are designed in such a way where you will need to periodically adjust the excess valve lash or "play" out of the valvetrain by adjusting the mechanical rocker arms.

All the B2200 engines (1987-1993) had hydraulic lash adjusters in the end of the rocker arms and they need no periodic adjustments.....but they do get worn and/or clogged with grit or debris and therefore start to tick.

Adjusting the mechanical rockers is a fairly easy job to do if you are mechanically inclined, if not, any auto repair shop can do this for you.

If they have never been adjusted........it's time!

I need to look in one of my 1986 or 1987 user manuals to see what the interval is for the mechanical valve adjustment.......I'll see if I can find the info and post it here.

The interval for adjusting the mechanical rocker arms (or valve lash adjustment) is every 15,000 miles according to the 1986 B2000 Owners Manual.

Post was last edited on Feb 07, 2012 03:58. Edited 1

time.

axel breaker earl

+1y

Actually Dan, the B2000 only had mechanical rockers......there is a threaded stud in the end of the rocker arm and it has a 12mm "jamb nut" that locks the threaded insert in position once you have the valve lash set to the specified tolerance.

So, the B2000 engine really doesn't have a "lifter" so to speak.

The B2200 engine has the Hydraulic Lash Adjusters (HLA's) in place instead of the threaded stud and jamb nut. A lot of members will replace the B2200 HLA rocker arms in their 2.2 engines with the earlier B2000 mechanical style rocker arms when they start experiencing the dreaded "tick-tick-tick" of the worn out HLA's.

Mechanical rocker arms and they're related valvetrain (like the camshaft!) are actually a very desirable item to have, so I wouldn't change from mechanical rockers to hydraulic rockers.......I would do the opposite!

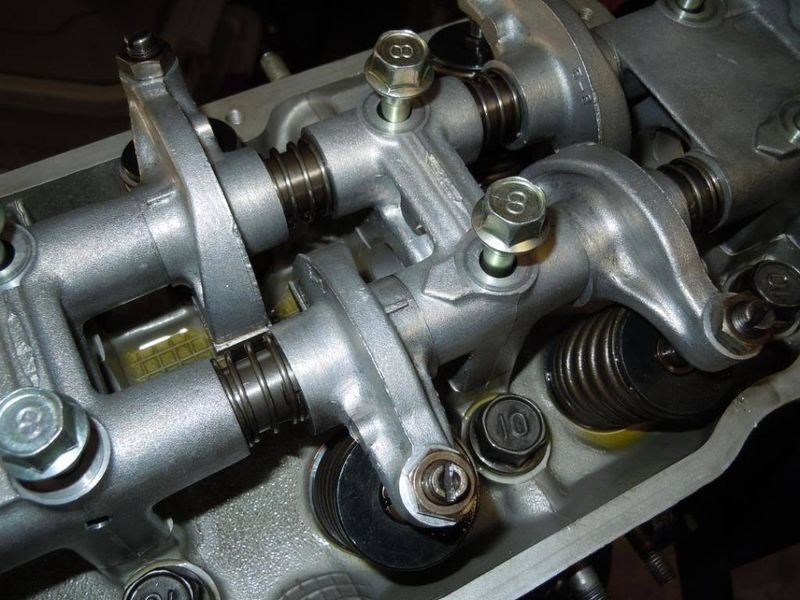

Here is a pic of the last engine I put together and it is a 2.2 (B2200 engine) with mechanical valvetrain from a 2.0 (B2000 engine) including the "mechanical styled" camshaft.

Post was last edited on Feb 07, 2012 03:33. Edited 1

time.

vieyra e p

+1y

yes my b2000 is 2nd gen. Ive read the chilton book on the adjustment and tried using the feeler gauge. just dont know how to use them the right way. Should the feeler gauge be really tight when adjusting the rocker arm, or just snug?

axel breaker earl

+1y

Just snug, so you can slid it in and out with some resistance. Are you using the .012" feeler gauge, and are you making the adjustment while the engine is warm?

I actually set mine a bit tighter.......I use a .009" feeler gauge while the engine is warm.

I actually set mine a bit tighter.......I use a .009" feeler gauge while the engine is warm.

dan woodland

+1y

Thanks Earl, I obviously didn't remember it right.

vieyra e p

+1y

I was doing it while it was cold with the .012 feeler gauge it was snug but not tight.

axel breaker earl

+1y

LOL, your welcome Dan! You had the gist of it anyway!

Vieyre e p, I would try setting them with it warmed up, yeah, it'll be cold by the time your done but try it that way anyway, and use the .009" feeler gauge and see if that helps......sometimes the tip of the threaded adjustment stud is worn on one edge and it may just naturally make some noise because of that, but it should be minimal I would think.......my valves on the engine pictured above make no noise at all......it is quiet as a mouse!

Vieyre e p, I would try setting them with it warmed up, yeah, it'll be cold by the time your done but try it that way anyway, and use the .009" feeler gauge and see if that helps......sometimes the tip of the threaded adjustment stud is worn on one edge and it may just naturally make some noise because of that, but it should be minimal I would think.......my valves on the engine pictured above make no noise at all......it is quiet as a mouse!