Wiki Home \ Front fender How to with pics

View Photos

Then bend the 3/4 over 90 degrees

Then bend the 3/4 over 90 degrees  Now i know most people dont have a brake so when you make your cut add 2" so it will bend better, then use angle iron or some other flat steel put the tin between and clamp it then bend the 90 deg that you need then cut the extra 2" off. Now we tried 1" between bends and that wasnt enough so on the outside of the bend make a mark every 1/2" .

Now i know most people dont have a brake so when you make your cut add 2" so it will bend better, then use angle iron or some other flat steel put the tin between and clamp it then bend the 90 deg that you need then cut the extra 2" off. Now we tried 1" between bends and that wasnt enough so on the outside of the bend make a mark every 1/2" .  We made a quick tool to speed things up and make it so one person could do it.

We made a quick tool to speed things up and make it so one person could do it.  Now notice how the end is round thats so it wont get to close to the bend and leave a mark when clamping. The bottom has a 1/2" slot at the bottom for the top to set into. If using the tool then clamp down every mark and watch it start to shape.

Now notice how the end is round thats so it wont get to close to the bend and leave a mark when clamping. The bottom has a 1/2" slot at the bottom for the top to set into. If using the tool then clamp down every mark and watch it start to shape.

See how the ends round to keep away from the bend

See how the ends round to keep away from the bend  Ok for you guys that dont want to make the super tool here is another way to do it its just harder to make them all the same and takes 2 people. Take a block of wood dig a small hole in the end

Ok for you guys that dont want to make the super tool here is another way to do it its just harder to make them all the same and takes 2 people. Take a block of wood dig a small hole in the end  Or you could make it from steel to make it last. Then take a dull chisel or flat head (with tip broke off) and hammer and tap at all the marks

Or you could make it from steel to make it last. Then take a dull chisel or flat head (with tip broke off) and hammer and tap at all the marks  . I then put the fender in the truck for fitting you can bend it a little more or take some out to make it fit just right, make sure you get it all set before moving on. Now trace out the fender on some 20ga for the lip i went right on the top then the inside i went 1/4" more to cover more.

. I then put the fender in the truck for fitting you can bend it a little more or take some out to make it fit just right, make sure you get it all set before moving on. Now trace out the fender on some 20ga for the lip i went right on the top then the inside i went 1/4" more to cover more.

Then cut it out and place it over the fender kepping it down from the bend just a little so when you weld you have room

Then cut it out and place it over the fender kepping it down from the bend just a little so when you weld you have room  I tacked it with very small tacks untill allmost the whole thing was welded also very small tacks on the inside were the metal touched. Then clean up the welds

I tacked it with very small tacks untill allmost the whole thing was welded also very small tacks on the inside were the metal touched. Then clean up the welds

When you get done with the trim it might need a little finish up with the hammer to make it all straight but dont beat the dimples out it will take the bend away and warp the fender. I will add a few little things to this as people ask so check this page for updates.

When you get done with the trim it might need a little finish up with the hammer to make it all straight but dont beat the dimples out it will take the bend away and warp the fender. I will add a few little things to this as people ask so check this page for updates.

Front fender How to with pics

Last Updated: Feb 24, 2015View Photos

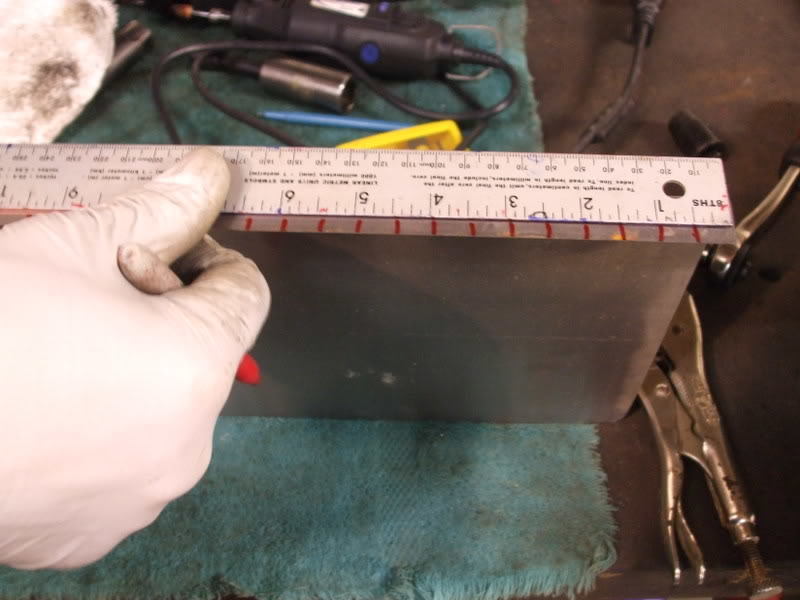

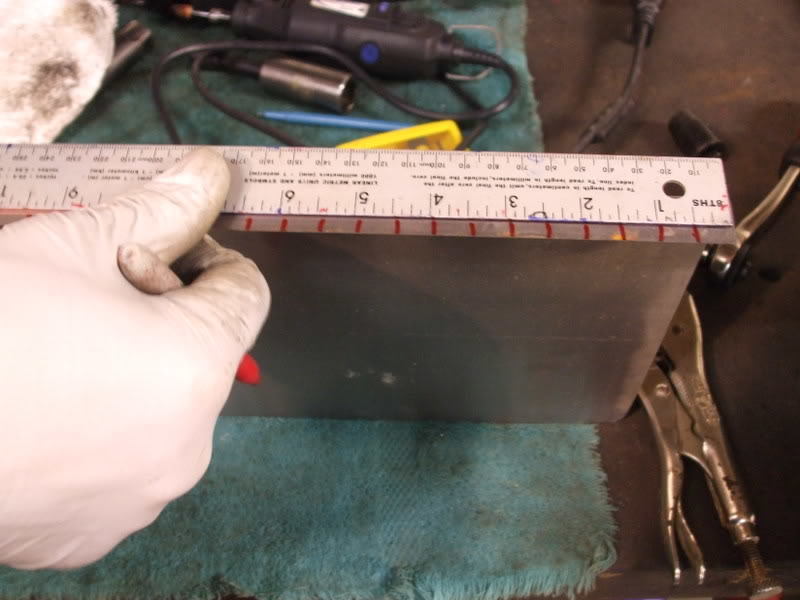

Well not sure how many people will use this. We used 20ga steel for this. First you need a measurement for the opening mazdas front are 35" from firewall to front were it goes flat. The width will depend on you we went 7" wide and it looks good. Ok when you do you layout for cutting make sure you add 3/4" on the long side for the bend so we went 7 3/4"

Credits

Created By: dirtracer14

Page 1 of 2

dirtracer14

+1y

Well heres what we got so far.. let us know if you want to see more and if you want a write up on it or not.

The tool we fabbed up in a couple of minutes haha

The tool we fabbed up in a couple of minutes haha

sleepyspeed

+1y

I'm with Baha on this. Sheet metal fab is a good thing to learn and there is always a trick or two to be learned from some one else.

jmzcustomz (jeff)

+1y

Dude that is soooo Sweet and inexpensive. Especially if the vise grips come from Harbour Frieght. LOL

I would have to agree...do a formal write up with tons of pics!!!!

Front inner fender making time with Dirtracer....

I would have to agree...do a formal write up with tons of pics!!!!

Front inner fender making time with Dirtracer....

v8mazda4ever

+1y

Like the work... not trying to cause any crap but just wondering why not use a set of trailer fenders and weld them in I know it is not the same but it gives you the perfrect shape. just asking.

corky

+1y

awsome idea on fabbin ur own fenders, its cool to se someone do that instead of buying trailer fenders

Page 1 of 2