Is this a bad design idea? or will it work fine....

1124 views

38 replies

31 following

Is this a bad design idea? or will it work fine....

trashed

+1y

Edited: 2/5/2007 10:48:48 AM by trashed

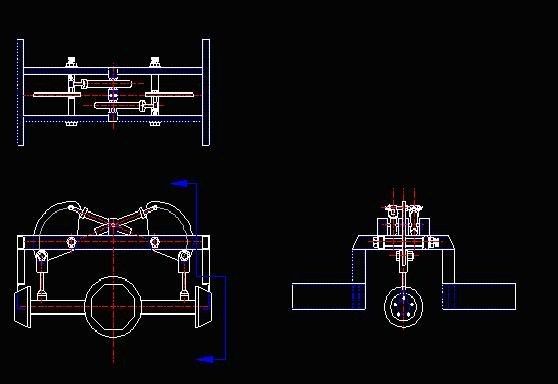

a friend of mine designed a similar link setup in cad that im going to run on my mazda and this is what we found was the most effective....

the shaf of the cylinder is going to be mounted on a pivot bar, the top of the cylinder will by mounted with a pivot point to the lever. the lever has 3 pivot points with another bar that mounts to the axle with a showball which allows the axle to articulate. the 4 link will keep the axle located, the lever setup's only purpose is the same as an over the axle bag or coil.

in your application you can apply some of the same things. mount your cylinder with a show ball on the bottom to keep it from binding and bending the cylinder. keep your middle pivot fixed on the bottom and your axle mount the same as your cylinder, showball on the axle. try and keep your bars from the cylinder to middle and middle to axle close to the same length to avoid stress. i think i just about covered it, if its confusing i appologize. simple is better, keep that in mind.

a friend of mine designed a similar link setup in cad that im going to run on my mazda and this is what we found was the most effective....

the shaf of the cylinder is going to be mounted on a pivot bar, the top of the cylinder will by mounted with a pivot point to the lever. the lever has 3 pivot points with another bar that mounts to the axle with a showball which allows the axle to articulate. the 4 link will keep the axle located, the lever setup's only purpose is the same as an over the axle bag or coil.

in your application you can apply some of the same things. mount your cylinder with a show ball on the bottom to keep it from binding and bending the cylinder. keep your middle pivot fixed on the bottom and your axle mount the same as your cylinder, showball on the axle. try and keep your bars from the cylinder to middle and middle to axle close to the same length to avoid stress. i think i just about covered it, if its confusing i appologize. simple is better, keep that in mind.

C

CanadianSplash

+1y

A few years back they did a set up like troys design using air cylinders in the back of an S10 in a magazine, it was a sick set-up and looked like it got some good lift, i will see if i can find the picture of it online

B

bagdb2200

+1y

This pic kinda illustrates the type of setup Troy posted, but doesn't really help you with your question....

C

CanadianSplash

+1y

yeah that is a similar set up as the s10 i seen, but his air cylinders were set at a 45 degree angle, but basically same thing

wht01ranger

+1y

Originally posted by Russ-D

RE: your first drawing:

My statics experience says that unless the forces are equal either by loading or by ratio changes, that the center link bar will be pushed with a horizontal component of force to the weaker side.

Additionally, dynamics says that the resistance of the bag to compression will exert the force sideways as well under instantaneous forces (speedbumps, rocks in the road)

That is my opinion with education in both statics and dynamics. The real world application will encounter other variables, like friction at the bushings, and torque on the bars.

The "Center" link isn't going to rock back and forth freely because it's indirectly connected to 1 stationary point, the axle. It will follow the range of motion of the axle in relation to the force applied, the bag. The link can only "rock back and forth" as far as the "axle" will let it, not any further, unless the connection to that stationary point breaks, such as a broken bolt, mounting tab, etc.

Jeff's case, he did the experimentation already and stated the link does not hit the bag througout its motion. So he's fine.

But the problem is with that you say next Russ. Everytime that axle articulates, rather than the "dog bone" link taking most of the stress, now you have the entire assembly taking the stress because the lever arm is directly mounted to the axle. Something's gotta give.

RE: your first drawing:

My statics experience says that unless the forces are equal either by loading or by ratio changes, that the center link bar will be pushed with a horizontal component of force to the weaker side.

Additionally, dynamics says that the resistance of the bag to compression will exert the force sideways as well under instantaneous forces (speedbumps, rocks in the road)

That is my opinion with education in both statics and dynamics. The real world application will encounter other variables, like friction at the bushings, and torque on the bars.

The "Center" link isn't going to rock back and forth freely because it's indirectly connected to 1 stationary point, the axle. It will follow the range of motion of the axle in relation to the force applied, the bag. The link can only "rock back and forth" as far as the "axle" will let it, not any further, unless the connection to that stationary point breaks, such as a broken bolt, mounting tab, etc.

Jeff's case, he did the experimentation already and stated the link does not hit the bag througout its motion. So he's fine.

But the problem is with that you say next Russ. Everytime that axle articulates, rather than the "dog bone" link taking most of the stress, now you have the entire assembly taking the stress because the lever arm is directly mounted to the axle. Something's gotta give.

wht01ranger

+1y

It will work, but like everything, it has its flaws. I'd say this would be a good setup for a 2link. Mainly because 2links do not articulate. You would not have a problem with articulation putting the cantilever under a lot of stress.

dssur

+1y

I assumed he would use a rod on the axle side too, if he set it up like the one in the picture the horzintal componet would be ineffective until it became larger than the vertical component, in which case the center pivot would move downward and the rear bag/cylinder pivot would move horizontally.

Mounted like in the picture, the limit is only the arc of operation.

Mounted like in the picture, the limit is only the arc of operation.

4uh8rs

+1y

THANKS FOR FOR THE INTREST IN MY SET UP TAYLOR...MY HONEST ANSWER IS IM NOT SURE HOW WELL IT WILL WORK RIGHT NOW.....AS FAR AS THE RANGE OF MOTION IT IS FINE...THE PIC BEING USED IS WITH AN ASS TON OF AIR IN THE BAG AND RIGHT AT11.5 INCHES OF LIFT...IM ONLY GONNA USE 9.5 WHENI TS DONE....I TALKED TO SEVERAL PEOPLE IN THE INDUSTRY THAT HAVE "BIG" NAMES AND THEY SAID HEY IT WILL WORK....AND THEN PUT IN THERE ADVICE....IM GONNA GRAB THE BALL AND RUN WITH IT AND HOPE ITS OK......I GUESS SINCE WE DIDNT DO A 2 TO 1 AN OTHE ARM THE PIVOT ARM KEPT SHEARING OFF THE FRAME SO WE DID THE DOULBE LINK ENDS AND IT LIFTS AND OPERATES FINE...ALSO TAYLOR THANKS FOR LETTING EVERYONE KNOW THAT YOU WERE NOT TRYING TO DOWN MY WORK THAT YOU WERE JUST LOOKING FOR SOME ADVICE

wht01ranger

+1y

Originally posted by Russ-D

I assumed he would use a rod on the axle side too.

Mounted like in the picture, the limit is only the arc of operation.

That's true. The lever would pretty much be a "floater," which do as you said, move to towards the weakest side.

I think he isn't using another link on the axle side though. So yes, your last statement is what I was saying.

I assumed he would use a rod on the axle side too.

Mounted like in the picture, the limit is only the arc of operation.

That's true. The lever would pretty much be a "floater," which do as you said, move to towards the weakest side.

I think he isn't using another link on the axle side though. So yes, your last statement is what I was saying.

Related Discussions in Air Ride Suspensions

Thread

Posts

Last Post