My Truck Build Up: 2006 F150: 26s, 6 15's, 22,000 watts

2532 views

27 replies

16 following

D

My Truck Build Up: 2006 F150: 26s, 6 15's, 22,000 watts

D

dwright

+1y

Im a new member here but have been lurking for quite sometime, this is my audio build log, but should be working on the suspsension soon. If Moonshine Customs is still around they will be doing the front half at least. I called Jose over at Drops R Us but he hasnt returned my call. anyway, here is a quick rundown.

Equipment List:

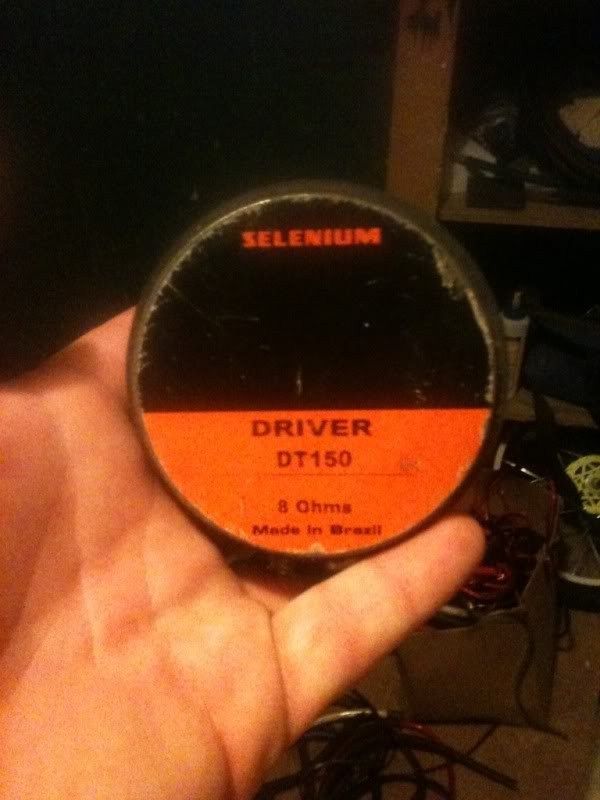

Alpine 9856 with CD Changer6 DC Audio 3.5ks2 - 3 DC Audio 175.4sXS Power D6500 under hoodXS Power D3100s or XP3000 or D1600 for a 16 Volt Setup1/0 Welding and normal wire everywhere6 DC Audio XL 15sMechman or DC Power Alternators.Selenium Horns/Super Tweeters12 GRP 6.5" Mids Custom Door Panels

ETC ETC.

Equipment List:

Alpine 9856 with CD Changer6 DC Audio 3.5ks2 - 3 DC Audio 175.4sXS Power D6500 under hoodXS Power D3100s or XP3000 or D1600 for a 16 Volt Setup1/0 Welding and normal wire everywhere6 DC Audio XL 15sMechman or DC Power Alternators.Selenium Horns/Super Tweeters12 GRP 6.5" Mids Custom Door Panels

ETC ETC.

tuckinlugs06

+1y

nice ...i just put 2 custom built t3 18's in my f150 ...under window line for now but might wall later on

D

dwright

+1y

ok, so for anyone who HASNT done any type of glass work before, now is your chance to get some pictures going to give you an idea. Also, check out Timmays section, his name on the site is groundpounder2k2 and he is the shiz.

ok, so first the explanation:

the box wasnt totally square and when we forced the port in, seperated my baffle from the side of the box a little. no big deal, filled it with liquid nails, and screwed it a little more and pulled it back closer. the liquid nails was then allowed to set up and harden a good bit. i didnt show it but, i used a flashlight ( works best at night ) to see where any slack spots where as far as liquid nails went, this told me where i may run into the most problems with air leaks etc. so that where i put the heaviest layers. i glassed the seams where the port meets the side and the front panel where it seperated as well as on the rear of the front panel, before i ran out of mixing supplies. so heres the pictures.

ok, before you do ANYTHING youre gonna wanna cut up your chop mat/cloth first into the strips/sections you will need. i think it comes in like 2 foot by 4 foot sheets.

i ended up cutting 6 layers for each side wall and port seams first.

my cloth cutting skills arent that great so i put the 2 biggest strips on top and bottom to sanndwich the smaller pieces in between them.

then i test fitted my strip.

And here is my void i filled with liquid nails and the main section i was worried about making strong.

i then got my supplies ready, to start mixing up the resin. laid an old shirt down to keep the resin from dripping on my floor. I also went through about 30 pairs of nitrile gloves during the process, so those are a MUST.

i then mixed my resin and layed down a "base coat" if you will that gets your first layer wet and sticky. When i mix my resin and hardner i use 20 - 22 drops per ounce of resin. usually i guess at the amount of resin. this is a decently hot mix, as i work a little fast and the hot mix pushes me to wor quicker so it doesnt set up on me. for a beginer i recommend a 14 - 18 per ounce mix.

first layer.

a laer or 2 in

and the front half. this spot got 7 layers on the front maybe a few more, and around 9 layers on the back side.

and repeat process for the other side which also got 6 layers on the seam where the port meets the side wall., only difference is this side doesnt have a gap at all.

D

dwright

+1y

And 9 of 12 mids re wired.

Those are going in the trim panels beside your head ..... Should get a little loud?

Then there were these.

Got the passenger side done minus the horn.

Got the passenger side done minus the horn.

Im sure i missed a few pictures but that sums up my ever continuing build. I work on it when i can ( will be easier sooner when i start my new job on the 17th and go to day shift ) as i work 60+ hours a week and have a life outside of audio and building shit. so let me know what you guys think. I think i kinda eliminated myself from doing a body drop unless i take the wall out :( which probably wont happen lol unless i can get away with a SFBD?

D

dwright

+1y

--------------------------------------------

TuckingLugs05 said:

nice ...i just put 2 custom built t3 18's in my f150 ...under window line for now but might wall later on

--------------------------------------------

what model? TSNS? T3 is cool but i wouldnt use them, their customer service is to unreliable, unless youre dealing with Ed Lester.

TuckingLugs05 said:

nice ...i just put 2 custom built t3 18's in my f150 ...under window line for now but might wall later on

--------------------------------------------

what model? TSNS? T3 is cool but i wouldnt use them, their customer service is to unreliable, unless youre dealing with Ed Lester.

Layumon22s

+1y

Moonshine Customs is no longer in business. they didn't do suspension work anyway... good luck with the build

D

dwright

+1y

i remember talking with Dave ( i think his name is about your truck ) iirc they had another person do the suspension work for them?

tuckinlugs06

+1y

no they are 100% custom only used t3 motors, sundown baskets , dd soft parts

D

dwright

+1y

lol, franken subs. Custom subs are cool especially being as no one else will have the same sub unless you or they copied each other lol. What T3 motor does your sub use?

how did you get your hands on DD soft parts? i got fed up with thier "send in your sub" bullshit because if i ever needed a recone i would have to pay shipping both ways ( usually $50 per sub going and another $50 returning ) then pay for a recone with mediocre parts. Ive been a dealer for DC for the last 4 years, and never looked back.

LOVE these friggin subs and will never run a different companys subs as long as theyre in business. their customer service is the best by far.

Are there any reputable shops close to bag my truck on 6s? Im thinking my rear end may need to be narrowed because of the fender flares and tires are almost perfectly lined up with the tires sticking out a hair. Ive got about $3-$4000 to spend for everything.

how did you get your hands on DD soft parts? i got fed up with thier "send in your sub" bullshit because if i ever needed a recone i would have to pay shipping both ways ( usually $50 per sub going and another $50 returning ) then pay for a recone with mediocre parts. Ive been a dealer for DC for the last 4 years, and never looked back.

LOVE these friggin subs and will never run a different companys subs as long as theyre in business. their customer service is the best by far.

Are there any reputable shops close to bag my truck on 6s? Im thinking my rear end may need to be narrowed because of the fender flares and tires are almost perfectly lined up with the tires sticking out a hair. Ive got about $3-$4000 to spend for everything.

wickedinsides

+1y

Interesting choice of materials

Related Discussions in Build-Ups

Thread

Posts

Last Post

32

last post by

baha 2 mo

0

V

last post by

Vic 7 mo

168

last post by

truck action +1y