91 B2600i...A/C Compressor Cycling...**Updated with PICS**

8210 views

31 replies

6 following

91 B2600i...A/C Compressor Cycling...**Updated with PICS**

nilesheen87

+1y

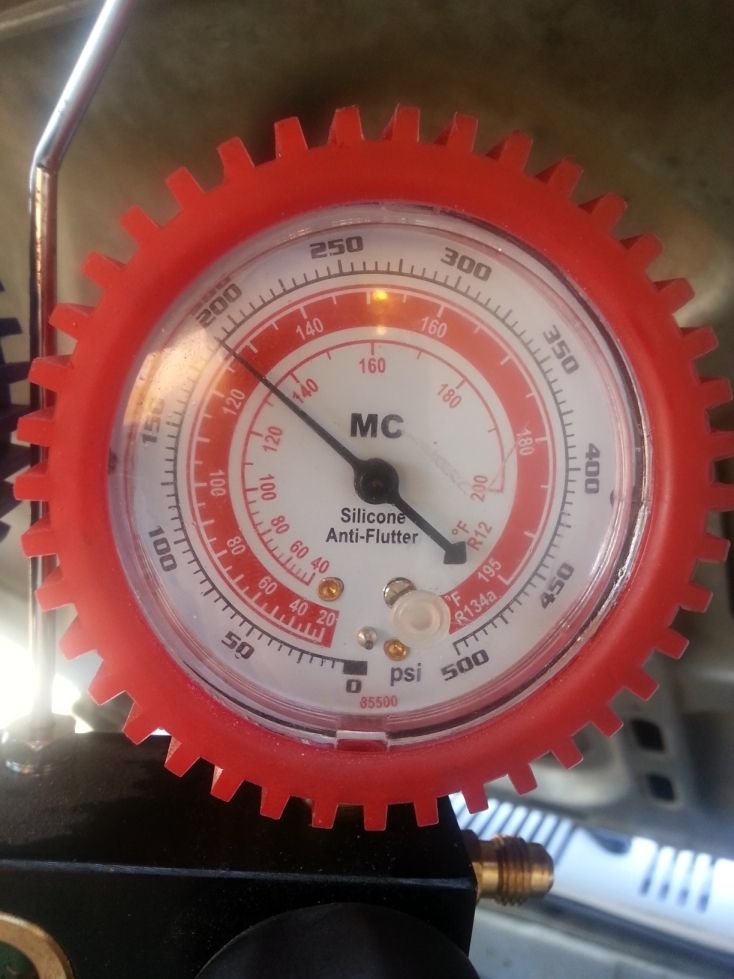

Ok, did pressure test one more time. Outside temperature was 80 Deg F. Blue Gauge is low pressure side, and Red Gauge is High Pressure. Each gauge had three rings of numbers, wasnt sure which one to read, but you guys tell me what you think....

**Deleted Pics that were too large, resized images on next post**

**Deleted Pics that were too large, resized images on next post**

nilesheen87

+1y

Ok, so these are the pics I took while performing the pressure test today. Outside Air Temp was approx 80 Deg. F, and engine was being held at 2000RPM during test, with A/C on max setting and recirculation on.

Please let me know if these pressures seem right, too high or low. Again, I'm running R134 in stock system.

(To add further to the mystery of the compressor cycling, i've noticed a pattern that it will only click off once my vent temperature reaches approx 50 degrees F. It then stays disabled until vent temp goes up to about 60 F. Ive also noticed that it never seems to click off when im running max blower speed, only speed #3 or less....but always around 50 degrees out of the vents on those blower speeds and compressor will click off.)

Could I have an issue with both my pressure being too low, and my defrost switch kicking on too? I assumed if I was low on r134, evaporator would never get that cold enough to trigger the defrost switch from disabling compressor. Surely 50 degrees at the vents wouldnt put the temp at the evaporator at the 35 Degrees to trigger the defrost switch would it??

Please let me know if these pressures seem right, too high or low. Again, I'm running R134 in stock system.

(To add further to the mystery of the compressor cycling, i've noticed a pattern that it will only click off once my vent temperature reaches approx 50 degrees F. It then stays disabled until vent temp goes up to about 60 F. Ive also noticed that it never seems to click off when im running max blower speed, only speed #3 or less....but always around 50 degrees out of the vents on those blower speeds and compressor will click off.)

Could I have an issue with both my pressure being too low, and my defrost switch kicking on too? I assumed if I was low on r134, evaporator would never get that cold enough to trigger the defrost switch from disabling compressor. Surely 50 degrees at the vents wouldnt put the temp at the evaporator at the 35 Degrees to trigger the defrost switch would it??

Cusser

+1y

At speed 3, the blower fan is slower so the evaporator will actually deliver COLDER air, as longer residence time. If you measure the vent temperature in the middle after 15 minutes of running using a slow fan speed, I'd guess your vent temperatures will be lower. "Cooling feeling" is an intricate mix of air speed and air temperature.

Yes, 35F at the evaporator de-icer sensor can deliver 50F air to the vents, because the vents have heat sink capacity for at least 15 minutes. Actually, the radio mechanic here in Phoenix tells people that 55F or lower from the vents is "working system" but I don't really go along with that unless the vehicle's been parked in the sun.

The "real way" to add correct amount of refrigerant is by weight, and typically 80% of the R-12 amount is what's used on R134a conversions, so like 80% of 32 ounces.

nilesheen87

+1y

So, in your opinion my pressures are where they should be and not too low? I'd be interested also in hearing back from Mr "Scotch" on your take of my readings as well.

If my R134 pressure is correct based on what you guys are seeing from those gauges, would next logical conclusion about the compressor cycling be that it's simply shutting down for these 20-30 second intervals due to the de-icer/defrost switch sensing that evaporator is getting too cold? If we can eliminate a low pressure issue, one would assume this would be the only possibility correct?

Also, if this is indeed the case, should there be such a noticeable change in vent temps during the 20-30 second cut-out's of the compressor? As I've stated, I will be getting about 50 degrees F temp at the vents and when compressor kicks off temp will jump to about 60 before it turns back on. And I can feel this.

Kinda wondering if it would be good idea to invest in a can of that A/C evaporator cleaner and soak the coils and try to vacuum out any gunk/debris that's accumulated in there.

If my R134 pressure is correct based on what you guys are seeing from those gauges, would next logical conclusion about the compressor cycling be that it's simply shutting down for these 20-30 second intervals due to the de-icer/defrost switch sensing that evaporator is getting too cold? If we can eliminate a low pressure issue, one would assume this would be the only possibility correct?

Also, if this is indeed the case, should there be such a noticeable change in vent temps during the 20-30 second cut-out's of the compressor? As I've stated, I will be getting about 50 degrees F temp at the vents and when compressor kicks off temp will jump to about 60 before it turns back on. And I can feel this.

Kinda wondering if it would be good idea to invest in a can of that A/C evaporator cleaner and soak the coils and try to vacuum out any gunk/debris that's accumulated in there.

Cusser

+1y

Yes, your refrigerant could be a little low, like 1/2 a can. Was the system evacuated before refrigerant was added?

By the way, I have used aerosol brake cleaner to clean my own evaporator coils, after detergent didn't work, after removing the lower cover. In my case it turned out the gunk was from a hole in the middle of the evaporator (back in 2002 or 2003).

By the way, I have used aerosol brake cleaner to clean my own evaporator coils, after detergent didn't work, after removing the lower cover. In my case it turned out the gunk was from a hole in the middle of the evaporator (back in 2002 or 2003).

nilesheen87

+1y

No, system was not evacuated this year prior to my adding in cans of r134. I had that done prior to me getting the system working last year, but did not evacuate this time around. Have simply been adding cans or r134 to existing gases in the system.

So, would you suggest that I add another 1/2 can of R134?

And Mr. Scotch, if I could get your opinion on my pressures as well?

Thanks again for all the replies.

So, would you suggest that I add another 1/2 can of R134?

And Mr. Scotch, if I could get your opinion on my pressures as well?

Thanks again for all the replies.

Cusser

+1y

Well, since I've now learned that you did not evacuate the system (to remove both moisture and air), any of my previous comments about your pressures are non-relevant.

To do decent work on automotive AC systems, one needs minimum of vacuum pump, good set of gauges, UV-dye and/or electronic refrigerant detection system, safety goggles, and decent hand tools. Without all these it's all just guesswork. Myself: I have all of these.

S

scotch

+1y

It's been a couple of years since I converted my B2600i to 134 so the numbers aren't fresh in my memory. In fact, they're clouded because I have worked on another vehicle's AC system a couple of times since then... and it was a 2001 model which was designed for 134. So those numbers are a little fresher in my mind. However, it seems to me like my hi/low pressure switch was set for 28 or 30 on the low side.... and my system does not cycle off on the low side with the 24 ounces of freon I put in it. So your numbers just sound a little low to me... at least on the low side. But I can't be sure.

Since you are saying the it kicks off every time around 50 vent temp, then that does sound like my original gut feeling, that your defrost switch was cycling.

The reason it doesn't ice up on level 4 is because the fan is pumping enough warm (relatively warm) air across the evap to prevent it from reaching 35 or the switch threshold.

To answer your earlier question, YES, they can ice up if they are a little low. And yes, you could have both switches cycling. Only you can determine with certainty why your system is cycling. So check the voltage on the low pressure switch I have described above and you will be able to determine whether it's the defrost switch or the low pressure switch. From what you've described, I think it may be the defrost but both Cusser and myself are speculating. If it was the low pressure switch, then you would see it doing it at the same low pressure point every time.... whether it be 15, 20, or 25 PSI (and kicking back on at the same (slightly higher) pressure everytime. The fact that it doesn't cycle on max speed also suggest that it's the defrost switch.

I know you are looking for an easy answer like add 8 ounces or add it until the low side is "X" and the high side is "Y." But there are no simple answers.

If it were me, I would do the following:

0. Use voltmeter to determine if defrost switch or low pressure switch is cycling.

1. Add a small amount of refrigerant with dye in it.

2. Inspect every inch of every lines for leaks with the UV flashlight. (if you have a dark garage, it will be easier to spot... otherwise, you might try it at night.) Focus hard on all of the connections; they have o-rings in them... the most likely place to leak. Also, look closely at the fittings on the compressor and around the front lower side of the compressor as there is a seal there that could also be leaking... much like front main crankshaft seal. Also inspect connections inside the evaporator case... see #3 below.

3. Remover lower evap case and inspect and clean. If it's never been cleaned, it will almost certainly full of dust, dirt, leaves, mold, mildew, carpet fibers, pet hair, ect. Cleaning it will restore more airflow to your vents... and as Cusser mentioned, that alone will make the air feel colder. And, it will probably get colder because you could easily have 30% or more of you airflow blocked on the front of the evap. You don't want your evaporator playing with one hand tied behind it's back in the AZ heat this summer... or spring for that matter!! So get in there and inspect and clean it.

4. If you find a leak, then I would get it serviced by an AC shop if you have the funds. If you have access to the tools, you can do it yourself. Some of the autoparts stores will let you rent a vacuum pump. If you do in fact want to do it yourself, comeback here and post and there will be plenty of us around to offer you some more guidance and tips. If you're on a budget, then you can probably continue to milk it a while longer so long as the leak doesn't get worse. But one thing is for sure, it won't get better by itself. And don't use any refrigerant with magic additives that will "recondition" your o-rings and stop your leaks. They only clog your system. You might have to look hard on the shelf for a can that does not have a "stop leak" additive. The last time I looked, there were 4 or 5 brands with stop leak and only one brand on the shelf that didn't have it. If your store doesn't have one without it, go to another one that does. Fix the leaks with a wrench and a new o-ring, not goo.

Here is an excellent thread on cleaning the evaporator.

" target="_blank" target="_blank" target="_blank

Your evaporator probably won't looks as bad being in the dry desert, but it will be dirty if it hasn't been cleaned in a long time.

Also, don't underestimate the amount of air that escapes though those "Band Clamps" if the foam has deteriorated to nothing. It can be substantial.

And last, I think Cusser already mentioned this, make sure that the blend door on main air handler is closing all the way with the temp set to full cold. If not, then some air will get behind it and be traveling through the heater core...further increasing the difference between the evap temp and the vent temp!

Since you are saying the it kicks off every time around 50 vent temp, then that does sound like my original gut feeling, that your defrost switch was cycling.

The reason it doesn't ice up on level 4 is because the fan is pumping enough warm (relatively warm) air across the evap to prevent it from reaching 35 or the switch threshold.

To answer your earlier question, YES, they can ice up if they are a little low. And yes, you could have both switches cycling. Only you can determine with certainty why your system is cycling. So check the voltage on the low pressure switch I have described above and you will be able to determine whether it's the defrost switch or the low pressure switch. From what you've described, I think it may be the defrost but both Cusser and myself are speculating. If it was the low pressure switch, then you would see it doing it at the same low pressure point every time.... whether it be 15, 20, or 25 PSI (and kicking back on at the same (slightly higher) pressure everytime. The fact that it doesn't cycle on max speed also suggest that it's the defrost switch.

I know you are looking for an easy answer like add 8 ounces or add it until the low side is "X" and the high side is "Y." But there are no simple answers.

If it were me, I would do the following:

0. Use voltmeter to determine if defrost switch or low pressure switch is cycling.

1. Add a small amount of refrigerant with dye in it.

2. Inspect every inch of every lines for leaks with the UV flashlight. (if you have a dark garage, it will be easier to spot... otherwise, you might try it at night.) Focus hard on all of the connections; they have o-rings in them... the most likely place to leak. Also, look closely at the fittings on the compressor and around the front lower side of the compressor as there is a seal there that could also be leaking... much like front main crankshaft seal. Also inspect connections inside the evaporator case... see #3 below.

3. Remover lower evap case and inspect and clean. If it's never been cleaned, it will almost certainly full of dust, dirt, leaves, mold, mildew, carpet fibers, pet hair, ect. Cleaning it will restore more airflow to your vents... and as Cusser mentioned, that alone will make the air feel colder. And, it will probably get colder because you could easily have 30% or more of you airflow blocked on the front of the evap. You don't want your evaporator playing with one hand tied behind it's back in the AZ heat this summer... or spring for that matter!! So get in there and inspect and clean it.

4. If you find a leak, then I would get it serviced by an AC shop if you have the funds. If you have access to the tools, you can do it yourself. Some of the autoparts stores will let you rent a vacuum pump. If you do in fact want to do it yourself, comeback here and post and there will be plenty of us around to offer you some more guidance and tips. If you're on a budget, then you can probably continue to milk it a while longer so long as the leak doesn't get worse. But one thing is for sure, it won't get better by itself. And don't use any refrigerant with magic additives that will "recondition" your o-rings and stop your leaks. They only clog your system. You might have to look hard on the shelf for a can that does not have a "stop leak" additive. The last time I looked, there were 4 or 5 brands with stop leak and only one brand on the shelf that didn't have it. If your store doesn't have one without it, go to another one that does. Fix the leaks with a wrench and a new o-ring, not goo.

Here is an excellent thread on cleaning the evaporator.

" target="_blank" target="_blank" target="_blank

Your evaporator probably won't looks as bad being in the dry desert, but it will be dirty if it hasn't been cleaned in a long time.

Also, don't underestimate the amount of air that escapes though those "Band Clamps" if the foam has deteriorated to nothing. It can be substantial.

And last, I think Cusser already mentioned this, make sure that the blend door on main air handler is closing all the way with the temp set to full cold. If not, then some air will get behind it and be traveling through the heater core...further increasing the difference between the evap temp and the vent temp!

Post was last edited on Apr 30, 2014 07:55. Edited 2

times.

Cusser

+1y

Good point Scotch: NEVER add any refrigerant that containers sealers or conditioners. Except for the correct type and amount of refrigerant oil, the only thing ever to add would be refrigerant and (optional) UV dye.

Which brings about another point - and don't overlook what I posted about air in your system and maybe moisture due to lack of evacuation and lack of replacing the drier, as both will decrease its cooling capacity - hopefully in the changeover/conversion to R134a that the person flushed out most/all of the R-12 mineral-type refrigeration oil, as that's not compatible with R134a refrigeration oils. That's important.

And my own system has had refrigeration leak over the years at the evaporator itself (already mentioned, replaced with brass/copper aftermarket unit) and at the high pressure line (hose) crimp connection (which I had repaired locally for $50). So check the crimps and any connections. Sometimes a leaky O-ring connection merely needs 1/64 turn of tightening to seal it.

Which brings about another point - and don't overlook what I posted about air in your system and maybe moisture due to lack of evacuation and lack of replacing the drier, as both will decrease its cooling capacity - hopefully in the changeover/conversion to R134a that the person flushed out most/all of the R-12 mineral-type refrigeration oil, as that's not compatible with R134a refrigeration oils. That's important.

And my own system has had refrigeration leak over the years at the evaporator itself (already mentioned, replaced with brass/copper aftermarket unit) and at the high pressure line (hose) crimp connection (which I had repaired locally for $50). So check the crimps and any connections. Sometimes a leaky O-ring connection merely needs 1/64 turn of tightening to seal it.

sincitylocal

+1y

When using brake cleaner to clean your evaporator, be careful! Some brake clean products will dissolve your polystyrene(styrofoam) insulation.

Related Discussions in General Discussion

Thread

Posts

Last Post

7

last post by

Babyfartzmageezaks530 +1y

5

A

last post by

Alreadyhavingissues +1y