91 B2600i...A/C Compressor Cycling...**Updated with PICS**

8215 views

31 replies

6 following

91 B2600i...A/C Compressor Cycling...**Updated with PICS**

Cusser

+1y

Lots of solvents will dissolve foam and styrafoam insulation, good catch. My evaporator's gunk turned out to be dried refrigeration oil mixed with dirt. Good old soap bubbles confirmed refrigerant leakage there after cleaning, right in the middle.

The gunk was so good on mine that it was keeping R-12 in; but with no air flow because of its blockage, there was no cooling volume at all, even though the trace air was cold. Anyway, the aftermarket evap has lasted over a decade so far, and was available locally (we have at least two large Internet/local AC places here that are good).

nilesheen87

+1y

So I have the can of brake cleaner, my plan was to take cover off, spray every nook and cranny I can get the nozzle into, let it sit for a few minutes and then use a high powered vacuum to suck anything out. Since evaporator is not angled, I don't think the cleaner and resulting gunk that comes off will come out naturally, so that's why I'm employing the vacuum. Actually, think the brake cleaner will air dry but any larger debris, dirt particles, etc, will need to be sucked out. I'll report back on any improvements in coldness/airflow once i'm done.

Also, the stock foam insulation was already badly deteriorating last time I took evaporator case apart and I did re-seal everything with duct tape. Every crack I could see where air possibly could escape, i covered in duct tape.

Also, for what it's worth, I did have to manually close the blend door this year prior to running the a/c. I noticed when turning temp knob to full cold, the blend door would shut about 90% of the way, but still left a crack exposed to heater ductwork. So I ended up closing it all the way myself and again sealed what I could see with duct tape.

Also, the stock foam insulation was already badly deteriorating last time I took evaporator case apart and I did re-seal everything with duct tape. Every crack I could see where air possibly could escape, i covered in duct tape.

Also, for what it's worth, I did have to manually close the blend door this year prior to running the a/c. I noticed when turning temp knob to full cold, the blend door would shut about 90% of the way, but still left a crack exposed to heater ductwork. So I ended up closing it all the way myself and again sealed what I could see with duct tape.

S

scotch

+1y

If you can't fix it, duct it!

If you've been in there recently, the you have an idea how dirty it is or isn't so maybe it's not too bad.

I would put a trash bag or towel down in the floorboard and vacuum and maybe gently scrub it with cleaner like simple green or the likes. You might even pickup some household coil cleaner from your local hardware store.... that will foam up and soak in the nooks and crannies (if it's even that dirty.) If you have a compressor, you can try blow it out from the back side.

nilesheen87

+1y

So interesting last few hours, took apart evaporator case, used the can of brake cleaner and sprayed what I could. Wasnt too dirty to begin with, but cleaned it out anyway and used a vacuum to suck out any little debris. Put everything back together and resealed it best I could.

I was looking under the hood for an unrelated item, when I stumbled upon an electric fan mounted in front of the condenser. Until today, I hadn't even noticed that it was there. Aftermarket item obviously, must have been installed by prior owner. Wasn't working though. Followed the wiring and led back to a relay setup and an inline fuse on the main power wire was blown. I put in a new fuse but fan still didn't engage. Ran a jumper and still....nothing. So my guess is motor is gone. It's a shame too because I would imagine having the operational would have at minimum helped out with my vent temperatures while at idle. I know in an ideal world the clutch fan should be sufficient, but that electric fan couldn't have hurt things.

I did remove the fan and assembly however since it does seem that would be blocking potential airflow thru the condenser.

I did test a/c after all this and air did seem to be blowing out a little harder and colder. The defrost switch actually kicked on when I had the blower on high, which almost never happened before, so def was colder.

Just out of curiosity, how much would an aftermarket fan like that one help out with my a/c temperatures? Almost considering buying a new one now. And can this 'defrost/de-ice' switch be bypassed, and what would be the consequences of doing this? Ive been told the system would fail, but specifically what would fail?

I was looking under the hood for an unrelated item, when I stumbled upon an electric fan mounted in front of the condenser. Until today, I hadn't even noticed that it was there. Aftermarket item obviously, must have been installed by prior owner. Wasn't working though. Followed the wiring and led back to a relay setup and an inline fuse on the main power wire was blown. I put in a new fuse but fan still didn't engage. Ran a jumper and still....nothing. So my guess is motor is gone. It's a shame too because I would imagine having the operational would have at minimum helped out with my vent temperatures while at idle. I know in an ideal world the clutch fan should be sufficient, but that electric fan couldn't have hurt things.

I did remove the fan and assembly however since it does seem that would be blocking potential airflow thru the condenser.

I did test a/c after all this and air did seem to be blowing out a little harder and colder. The defrost switch actually kicked on when I had the blower on high, which almost never happened before, so def was colder.

Just out of curiosity, how much would an aftermarket fan like that one help out with my a/c temperatures? Almost considering buying a new one now. And can this 'defrost/de-ice' switch be bypassed, and what would be the consequences of doing this? Ive been told the system would fail, but specifically what would fail?

S

scotch

+1y

A fan would almost certainly help at idle & very slow city traffic speeds. That electric fan would be pumping air the second you turn your truck on in the July afternoon heat... no waiting for the clutch to warm up and start working harder.

If you are already getting 35 temps at the evap, then it wouldn't change that much. Are you getting that cool at idle?

If not then you have something to gain. If you are already cycling at idle because it's that cold, it won't make much difference in the vent temps. But it would lower your high pressure...reducing the load on your compressor.

If you install one, you'll want it powered through a relay that is triggered by the signal going to the clutch. Compressor on = Fan On.

If you bypass the defrost, then your evap will ice up (if humid enough) and it will restrict airflow...making it ice even faster. You will end up with an evaporator ice cube.

If you are already getting 35 temps at the evap, then it wouldn't change that much. Are you getting that cool at idle?

If not then you have something to gain. If you are already cycling at idle because it's that cold, it won't make much difference in the vent temps. But it would lower your high pressure...reducing the load on your compressor.

If you install one, you'll want it powered through a relay that is triggered by the signal going to the clutch. Compressor on = Fan On.

If you bypass the defrost, then your evap will ice up (if humid enough) and it will restrict airflow...making it ice even faster. You will end up with an evaporator ice cube.

Cusser

+1y

1. You do not need a supplemental electric fan on these if the fan and fan clutch are working correctly. Your temperatures are only marginally cooler than ours in Phoenix.

2. Yes, one can "jump"/bypass that de-icer switch, but I don't recommend it. Yeah, your humidity level is pretty low, but you need to make sure that if the evaporator DOES get too cold and the compressor stays on, then liquid refrigerant could return to the compressor - and that's NOT compressible, which means that your compressor will bend or break something. So if you do jump it, put in some kind of toggle switch so you can turn off yourself regularly from the driver seat. Like I said: I DO NOT RECOMMEND THIS, just saying that it's possible.

I say fix leaks, evacuate, new drier, right level of refrigerant, then consider that you might be "there".

2. Yes, one can "jump"/bypass that de-icer switch, but I don't recommend it. Yeah, your humidity level is pretty low, but you need to make sure that if the evaporator DOES get too cold and the compressor stays on, then liquid refrigerant could return to the compressor - and that's NOT compressible, which means that your compressor will bend or break something. So if you do jump it, put in some kind of toggle switch so you can turn off yourself regularly from the driver seat. Like I said: I DO NOT RECOMMEND THIS, just saying that it's possible.

I say fix leaks, evacuate, new drier, right level of refrigerant, then consider that you might be "there".

vsawmike

+1y

I did A/C work back on the days of R-12 and on through the changeover to R-134A

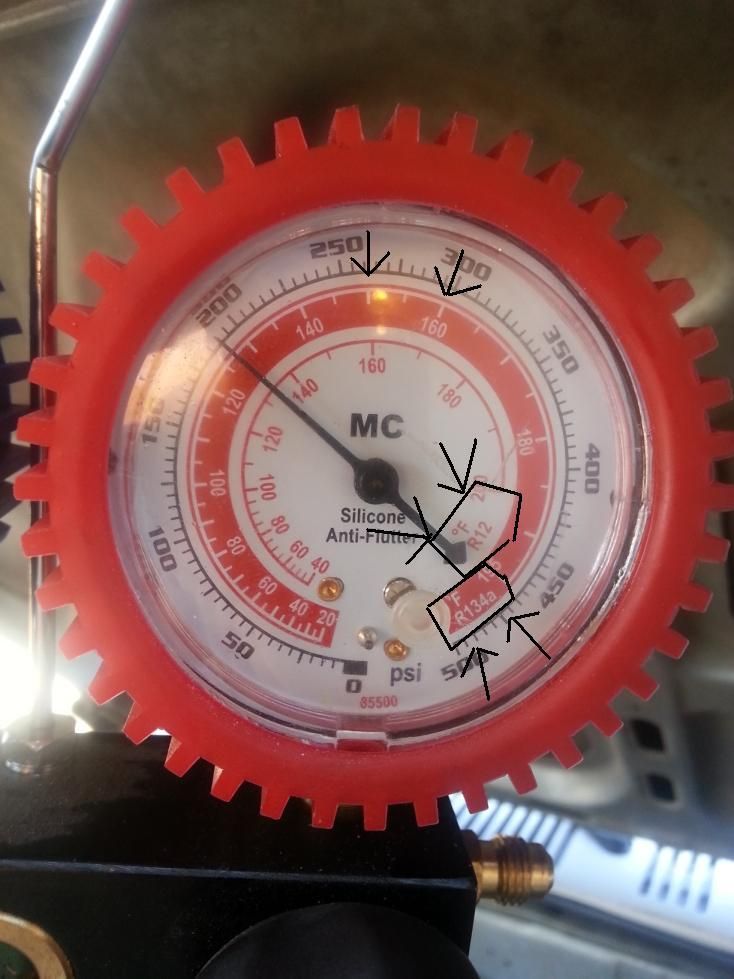

I was looking at the pics of the gauges. Those pressures are low for 134A and real low for R-12. This is why you are having a cycling of the clutch.

A partially stopped up expansion valve will also cycle like this but it will also show a much higher high side pressure.

To get the lowest temp out the vents you need 40 to 50 psi on the low side (134a scale not psi, or outer scale) This means that as the system runs just before the pressure switch clicks off the low side is at just above 40. The high side should be no higher than 150 on the 134 scale, not outer scale.

Many people read gauges wrong. A publication shows a certain pressure and the tech uses the PSI scale instead of the scale for the refrigerant used and ends up with a lower pressure than needed.

These pressures should be read with the A/C on, vehicle running at about 1500rpm (gas engine) with a fan in front of the vehicle. This simulates driving down a typical road at 40mph.

134A must have a higher pressure to cool even close to R-12.

When R-134A first came out it was suggested that pressures should be the same but later revisions recommended raising the pressure to get similar cooling.

Also when adding R-134A to an R-12 system you may experience less cooling because R-134A needs a larger condenser to cool properly. Some vehicles may have a larger than needed condenser such as a reg cab truck. Since the condenser is made a standard size on most trucks it has to cool a reg cab, ex cab crew cab etc.

All this comes down to one thing. When the A/C is running the low side needs to be between 40 and 60 and you will get cold air out the vent no matter what the high side says. The low side pressure is the most important.

Also some brake cleaners will take the coating off the aluminum fins in the evaporator and they will corrode and eventually degrade to where they fall out. If you have sprayed brake cleaner on the evaporator you may need to change it out.

You should never ever ever charge a system after opening or draining it without pulling a vacuum on it for at least a half hour in dry conditions. Longer of it's been wet outside and if the drier is old it needs to be replaced if you open the system.

Also many times a leak is in the schrader valves and is can just be tightened. Always change them when the system is opened.

I was looking at the pics of the gauges. Those pressures are low for 134A and real low for R-12. This is why you are having a cycling of the clutch.

A partially stopped up expansion valve will also cycle like this but it will also show a much higher high side pressure.

To get the lowest temp out the vents you need 40 to 50 psi on the low side (134a scale not psi, or outer scale) This means that as the system runs just before the pressure switch clicks off the low side is at just above 40. The high side should be no higher than 150 on the 134 scale, not outer scale.

Many people read gauges wrong. A publication shows a certain pressure and the tech uses the PSI scale instead of the scale for the refrigerant used and ends up with a lower pressure than needed.

These pressures should be read with the A/C on, vehicle running at about 1500rpm (gas engine) with a fan in front of the vehicle. This simulates driving down a typical road at 40mph.

134A must have a higher pressure to cool even close to R-12.

When R-134A first came out it was suggested that pressures should be the same but later revisions recommended raising the pressure to get similar cooling.

Also when adding R-134A to an R-12 system you may experience less cooling because R-134A needs a larger condenser to cool properly. Some vehicles may have a larger than needed condenser such as a reg cab truck. Since the condenser is made a standard size on most trucks it has to cool a reg cab, ex cab crew cab etc.

All this comes down to one thing. When the A/C is running the low side needs to be between 40 and 60 and you will get cold air out the vent no matter what the high side says. The low side pressure is the most important.

Also some brake cleaners will take the coating off the aluminum fins in the evaporator and they will corrode and eventually degrade to where they fall out. If you have sprayed brake cleaner on the evaporator you may need to change it out.

You should never ever ever charge a system after opening or draining it without pulling a vacuum on it for at least a half hour in dry conditions. Longer of it's been wet outside and if the drier is old it needs to be replaced if you open the system.

Also many times a leak is in the schrader valves and is can just be tightened. Always change them when the system is opened.

Cusser

+1y

Well if low side is too low, then the high side could also be low because of low refrigerant level. The right way is to measure both sides' pressures to get a good understanding of the system.

If the high side drops a ton when misting the condenser with water, then that indicates an air flow/condenser cooling issue.

vsawmike

+1y

What I was saying was on the gauge pics you showed the pressures are both low. Look at the gauge closely and notice that the inside red scale is the R-134a scale. Not the black outer scale. On the red inside scale you need the high side at 150-160 for R-134a.

If that were R-12 on the R-12 scale it needs to be 140 to 150. Again not on the outer black psi scale.

On the low side the inner blue scale is the one you need to pay attention to, not the outer black scale. '

The inner blue R-134A scale needs to be between 40 and 50. This will produce the coldest air out the vents no matter what other issues the vehicles have.

If that were R-12 on the R-12 scale it needs to be 140 to 150. Again not on the outer black psi scale.

On the low side the inner blue scale is the one you need to pay attention to, not the outer black scale. '

The inner blue R-134A scale needs to be between 40 and 50. This will produce the coldest air out the vents no matter what other issues the vehicles have.

vsawmike

+1y

See these gauges have both R-12 and R-134a scales.

Repair manuals will often refer to pressures for these and not the outer PSI scale.

40 on the low side equals cold air out the vents.

Looking at the pics above the system these gauges is hooked to is low. In this case the compressor will cycle on and off rapidly and not cool to it's potential.

get the low side to 40 on the scale for the refrigerant you are using and it will blow cold no matter what other issues the system has. If it's R-12 and it's not 100 degrees outside it will throw snowballs in the floor.

I did not go to school to learn A/C, I learned it back in the early 80s and have been doing it ever since in one form or another. Most recently it has been adapting factory and add on A/C systems to armored cars, SWAT vehicles and government vehicles.

When it comes to reading a manual and/or the sticker under the hood then adding the weight it says I say that is wrong. Many factors will change how much weight a system actually needs to preform it's best. Again 40 on the low side, while the vehicle is at 1500 rpms, inside fan on high, both doors open, in the shade or inside a garage, with a fan blowing into the grille will make the coldest air the vehicle is capable of.

Any other problems are a separate discussion. The only point I'm trying to make is the pressures are not good in those pics.

Related Discussions in General Discussion

Thread

Posts

Last Post

7

last post by

Babyfartzmageezaks530 +1y

5

A

last post by

Alreadyhavingissues +1y