Black crud in last two head bolts

5450 views

38 replies

5 following

S

Black crud in last two head bolts

R

rooftoplounge

+1y

Thank you very much for the tip! I'll give it a couple shots of PB blaster and let it sit for a day or so, then give it a go.

R

rooftoplounge

+1y

It worked!! Between the PB blaster a 21mm socket and a breaker bar, it came undone! Like you said it was stuck good. Thanks for the suggestion Befarrer!

Now off to set the timing... How do you know that piston #1 is at the TDC compression stroke by the crank keyway? (Does that make sense?) How do I keep the chain from slipping on the crank sprocket while putting the covers back on?

Now off to set the timing... How do you know that piston #1 is at the TDC compression stroke by the crank keyway? (Does that make sense?) How do I keep the chain from slipping on the crank sprocket while putting the covers back on?

befarrer

+1y

Isn't there a tensioner that will keep the timing chain tight? An easy way to find TDC on compression stroke, is to put a finger over the spark plug hole, it will blow out of the hole on the compression stroke (and out the exhaust on the exhaust stroke) Can use a screwdriver down the plug hole to measure piston to see when it is at the top, but should be when the key way is on the top.

Cusser

+1y

I'd suggest a drinking straw over a screwdriver or a long extension. And I've heard that some have used pencils then post that their eraser part broke off inside their cylinder, so go the straw route.

At TDC #1, both valves for #1 cylinder will be closed. If you are a revolution off, that will not be the case.

I just used the "straw" technique 2 months ago on my '98 Frontier, confirmed the TDC mark on the pulley before I painted those marks white.

befarrer

+1y

Yeah a straw would work better, softer.

If you need to time the motor because it is all out to lunch, move the crank 1/4 turn counterclockwise before the TDC mark (this will put all 4 cylinders 1/2 way down the bore to prevent valve to piston impact, even though I am pretty sure that wont happen anyway), then turn the camshaft to the alignment mark, which will have both valves closed on cylinder 1, then turn the crankshaft clockwise to the timing mark, install chain, and check if both alignment marks align, may be off by a tooth, if so, then adjust.

I found out that finding tdc on a rotary involves math lol, little more complicated (mark the pulley as the apex seal passes the rear leading and trailing plugs, then find out how many degrees the pulley moved between both plug holes, then figure out how many degrees the pulley has to turn to move the apex seal a certain distance to get the apex seal in the middle of the housing (BDC), keeping in mind the leading and trailing plugs are not equally distance apart from where the apex seal sits at BDC, front housing is opposite, so when the rear is at BDC, the front is at TDC). Doesn't help that the marks on the front pulley are supposed to be at 5 ATDC and 20ATDC, and that the pulley is timed to each engine, therefore if the pulley is changed, the lines don't line up. Mine were out by 25 degrees, and when timed properly according to the pulley, I was actually running a timing of 30 degrees ATDC.

R

rooftoplounge

+1y

Thank you guys for the tips!

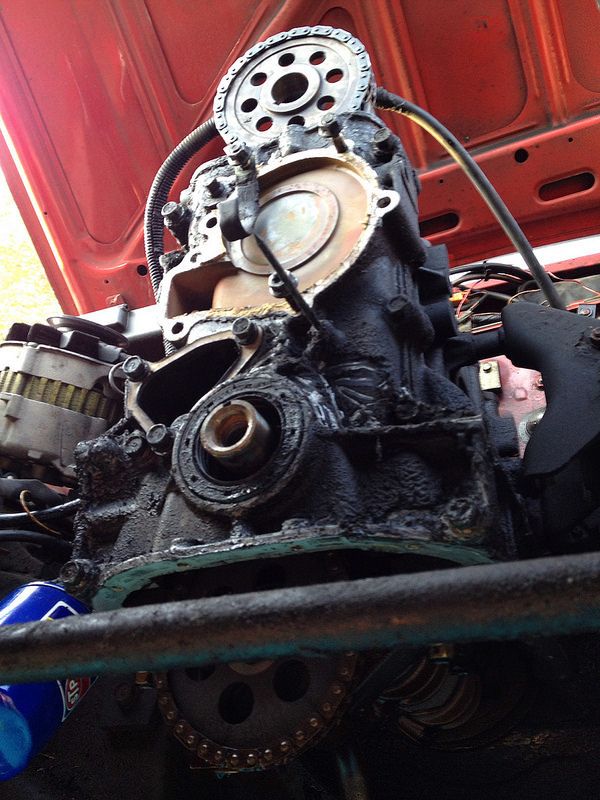

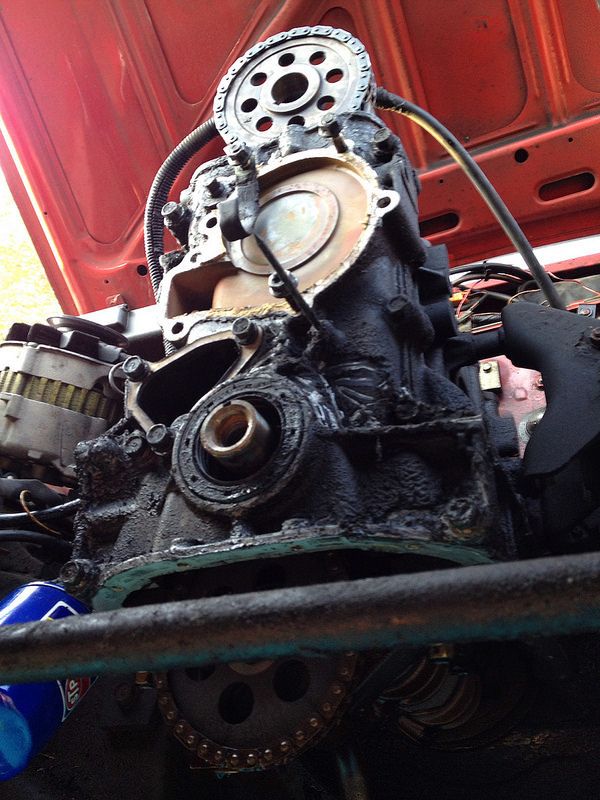

I have the 1970cc engine. The timing (I believe) is set by having the crank sprocket mark between the two nickel plated links and the cam sprocket mark (arrow on sprocket) one link after the single plated link or 44 links from the double link....? There are no other timing marks or indicators on the engine head/block, at least from what I can tell.

Is this an interference engine?

Found this while browsing, is this the way to set the timing? Thanks again guys for your input!

I have the 1970cc engine. The timing (I believe) is set by having the crank sprocket mark between the two nickel plated links and the cam sprocket mark (arrow on sprocket) one link after the single plated link or 44 links from the double link....? There are no other timing marks or indicators on the engine head/block, at least from what I can tell.

Is this an interference engine?

Found this while browsing, is this the way to set the timing? Thanks again guys for your input!

R

rooftoplounge

+1y

I've been busy working on some other projects but I'm getting back to the pickup shortly. I have a question about the automatic chain tensioner. How do I keep it pulled in until I get the cam sprocket back on? I can't seem to find the sweet spot where I can keep the tensioner from "springing" out. There is the tool mentioned in the manual but I've contacted the local car parts shops and they don't have one. Was that a dealer tool?

Is there a way to get around that? Thanks!!!

Is there a way to get around that? Thanks!!!

R

rooftoplounge

+1y

Hey All,

Its back together and RUNS!!!! I've driven it around the block a couple times and notice that its underpowered going up hills.

The issue I'm now having is that it has low compression (60-70psi) across all the cylinders. I haven't done the "add a little oil to each cylinder" yet but I did pour gas in them while the head was off to test the rings. At that time they all held gas for over 4 hours so I figured the rings were good. I should have -but did not do any work on the valves or have the head resurfaced. It hadn't overheated, it just had the head gasket blown between cyl 1 and 2. I also haven't set the timing with a timing gun yet.

Any advice? Thanks guys!

Its back together and RUNS!!!! I've driven it around the block a couple times and notice that its underpowered going up hills.

The issue I'm now having is that it has low compression (60-70psi) across all the cylinders. I haven't done the "add a little oil to each cylinder" yet but I did pour gas in them while the head was off to test the rings. At that time they all held gas for over 4 hours so I figured the rings were good. I should have -but did not do any work on the valves or have the head resurfaced. It hadn't overheated, it just had the head gasket blown between cyl 1 and 2. I also haven't set the timing with a timing gun yet.

Any advice? Thanks guys!

sincitylocal

+1y

Replace your compression gauge. If all 4 were between 60 and 70psi, it wouldn't run. Unless you're actually taking the reading wrong.

The proper way is to remove all the plugs, and crank the engine at least 7 revolutions with the throttle wide open, for each cylinder being tested.

The proper way is to remove all the plugs, and crank the engine at least 7 revolutions with the throttle wide open, for each cylinder being tested.

R

rooftoplounge

+1y

Thanks SinCity,

I'll give that a shot when I get home today. I forgot to mention that I've removed all the emissions crap from the carb and plugged the holes that I could find on the intake manifold. Like Befarrer said earlier it would run like the crappiest carb ever and I would have to agree. The plugs all got sooty after running it around the block. I'm assuming it would be because of the carb running rich.

I have a Weber 32/36 carb that I would like to put on but the adapter I picked up at the local Oreilles doesn't fit. Anyone know where I can find the correct adapter?

Thanks again!

I'll give that a shot when I get home today. I forgot to mention that I've removed all the emissions crap from the carb and plugged the holes that I could find on the intake manifold. Like Befarrer said earlier it would run like the crappiest carb ever and I would have to agree. The plugs all got sooty after running it around the block. I'm assuming it would be because of the carb running rich.

I have a Weber 32/36 carb that I would like to put on but the adapter I picked up at the local Oreilles doesn't fit. Anyone know where I can find the correct adapter?

Thanks again!