C

pinion angle

L

lownism0

+1y

Edited: 10/17/2005 4:09:07 PM by lownism0

how do you change the angle of the carrier bearing? Do you space it up so it creates an angle between the 2 shafts?

how do you change the angle of the carrier bearing? Do you space it up so it creates an angle between the 2 shafts?

P

periportfd

+1y

I wouldn't reference the carrier bearing. I'd use the front shaft angle and treat it like a tranny output. The carrier should be 90 to the front shaft but since your looking for the angle in relation to 0 degrees, it makes more sense to measure from the shaft since it's longer, has a easier surface to get a reading off of and is closer to the number you need.

P

periportfd

+1y

Originally posted by lownism0

Edited: 10/17/2005 4:09:07 PM by lownism0

how do you change the angle of the carrier bearing? Do you space it up so it creates an angle between the 2 shafts?

It is changing the angle of the carrier but the important part is that you are changing the angle of the front shaft. I try to work from the tranny back. The reason is that you still have to keep that front u-joint at proper angles. That's why alot of times kits will have a carrier bearing spacer and a tranny spacer. If you setup the rear first it can create extra work messing with spacers that you may not have needed. Another adjustment that most people don't even think about while they are cutting their whole truck apart, making spacers and grinding and rewelding every driveline piece they can touch is, simply add 10 or subtract 10 psi in your ride height and correct minor angle problems with the flick of a switch.

Edited: 10/17/2005 4:09:07 PM by lownism0

how do you change the angle of the carrier bearing? Do you space it up so it creates an angle between the 2 shafts?

It is changing the angle of the carrier but the important part is that you are changing the angle of the front shaft. I try to work from the tranny back. The reason is that you still have to keep that front u-joint at proper angles. That's why alot of times kits will have a carrier bearing spacer and a tranny spacer. If you setup the rear first it can create extra work messing with spacers that you may not have needed. Another adjustment that most people don't even think about while they are cutting their whole truck apart, making spacers and grinding and rewelding every driveline piece they can touch is, simply add 10 or subtract 10 psi in your ride height and correct minor angle problems with the flick of a switch.

bdroppeddak

+1y

so i think i about have it, but what about the carrier bearing, should it be angled or straight up and down will work??

sadisticiron

+1y

depending on how the link is set up depends on hoew the pinion is set of a triditional parallel 4 links you would want as close to zero as possible. but for a link set up for lift you want the rear end to follow the trans output shaft the best way possible and setting it up with a -5 degrees layed out provides the rear end with the right amount of pinion change to acheive this. theres a reason why my setups and other who practice this rule of thunb never have a problem with vibration

P

periportfd

+1y

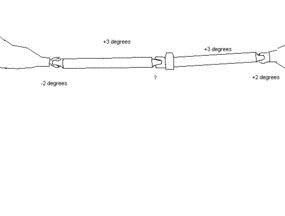

Well after getting my microscope out to read your numbers, it looks like you have +3 on the front and rear shaft. That means the angle going through the carrier is 0. Have you been listening Chris.......F+

Iownissan

+1y

well, atleast its an F+ and not just a regular F. hahah j/k chris. im actually learning alot by reading this too. they say you learn 1 new thing a day so i think im at my quitting point of learning today, i better nap! hahah

O

olskoolpup

+1y

im trying to get this whole 2-piece driveshaft pinion angle thing. say if i use cris's tiny diagram.

the front shaft angle is +3 deg. i would use that as the tranny angle. then set the rear end equal and opposite. -3 deg. is that right or do i join the ranks of cris in the flunky department??

the front shaft angle is +3 deg. i would use that as the tranny angle. then set the rear end equal and opposite. -3 deg. is that right or do i join the ranks of cris in the flunky department??

O

olskoolpup

+1y

bump

O

olskoolpup

+1y

please help a brotha out

Related Discussions in Chevy/GMC Trucks

Thread

Posts

Last Post

88-98 chevy/gmc 1500 rear end swap a few inches shorter (what did you use)

last post by

Oj557 +1y

25

25

last post by

Oj557 +1y

7

J

last post by

Jon +1y