Drop Member: Nissan Hardbody

ChadCrissDesign

+1y

--------------------------------------------

ScottXGTR said:

--------------------------------------------

ChadCrissDesign said:

I left infamousnissan.com because scottxgtr was a bad moderator.

--------------------------------------------

Yeah, Im a terrible administrator. I let you spit in the face of 3 people who build suspension parts for a living, who tried to give you advice. I even waited for the second time you did it to close your thread.

I tried giving you professional advice because no one will want to deal with you if you behave like a child. You got upset after people asked a few questions. Well guess what, if you ever decide to market this, you are going to get a lot of stupid repetitive questions from all sorts of potential buyers. If you plan to do business on my website, you will do so in a professional manner.

All that said, I hope you realize after getting some advice here that we were indeed trying to help you. Open your ears, and drop your ego and youll be a success. If/when you are ready to come back, your other threads are still open.

--------------------------------------------

Its one thing telling me the welds need to be hotter, another telling me how to sell my item. I didn

ScottXGTR said:

--------------------------------------------

ChadCrissDesign said:

I left infamousnissan.com because scottxgtr was a bad moderator.

--------------------------------------------

Yeah, Im a terrible administrator. I let you spit in the face of 3 people who build suspension parts for a living, who tried to give you advice. I even waited for the second time you did it to close your thread.

I tried giving you professional advice because no one will want to deal with you if you behave like a child. You got upset after people asked a few questions. Well guess what, if you ever decide to market this, you are going to get a lot of stupid repetitive questions from all sorts of potential buyers. If you plan to do business on my website, you will do so in a professional manner.

All that said, I hope you realize after getting some advice here that we were indeed trying to help you. Open your ears, and drop your ego and youll be a success. If/when you are ready to come back, your other threads are still open.

--------------------------------------------

Its one thing telling me the welds need to be hotter, another telling me how to sell my item. I didn

ChadCrissDesign

+1y

--------------------------------------------

Chopped Mazda said:

Edited: 12/6/2010 11:29:43 AM by Chopped Mazda

Aside from the design flaws......those welds are scary!

Also, just for the sake of saying it, thosre lowers arms wont last like that. Ive tested every thickness from .250 to 1" thick plate for lowers on everything from minis to full size trucks. Thats just way way to thin for a lower control arm, they will bend within a few hours on the road, and with the way you have the bag loaded on the arm, I wouldnt be suprised if they bent pulling out of the driveway.. ... if the welds done snap off of them first.

Taylor

--------------------------------------------

This right here is exactly the type of help that Im looking for, this is what I need. Thanks alot for the info.

Chopped Mazda said:

Edited: 12/6/2010 11:29:43 AM by Chopped Mazda

Aside from the design flaws......those welds are scary!

Also, just for the sake of saying it, thosre lowers arms wont last like that. Ive tested every thickness from .250 to 1" thick plate for lowers on everything from minis to full size trucks. Thats just way way to thin for a lower control arm, they will bend within a few hours on the road, and with the way you have the bag loaded on the arm, I wouldnt be suprised if they bent pulling out of the driveway.. ... if the welds done snap off of them first.

Taylor

--------------------------------------------

This right here is exactly the type of help that Im looking for, this is what I need. Thanks alot for the info.

tre5

+1y

It's not just the welds on the lower arm... it's all the welds. They need some extra talent, but you said you were taking care of that so...

I still see the biggest issue of this kit being.... you don't need it. The Nissan cross member will lay flat with the frame.

I still see the biggest issue of this kit being.... you don't need it. The Nissan cross member will lay flat with the frame.

ChadCrissDesign

+1y

--------------------------------------------

tre5 said:

It's not just the welds on the lower arm... it's all the welds. They need some extra talent, but you said you were taking care of that so...I still see the biggest issue of this kit being.... you don't need it. The Nissan cross member will lay flat with the frame.

--------------------------------------------

Well, i feel that its a pain in the butt to lay a hardbody out on 22's choping up stock parts. And its ugly using stock stuff.

tre5 said:

It's not just the welds on the lower arm... it's all the welds. They need some extra talent, but you said you were taking care of that so...I still see the biggest issue of this kit being.... you don't need it. The Nissan cross member will lay flat with the frame.

--------------------------------------------

Well, i feel that its a pain in the butt to lay a hardbody out on 22's choping up stock parts. And its ugly using stock stuff.

ahab

+1y

Your product is terrible and your attitude is worse. Even if you could figure out a way to make this setup stay together I doubt anyone would buy it from you. You are a "know it all" with very little experiance. Regarless of what welder you use, you should be able to weld good if you are a good welder. That is a lame excuse. The upper arm bushing attachment looks like a fail point. Another thing is, before you get on a website and start talking about selling your stuff you should really put some miles on your product before you even consider marketing, or producing it for the public. There have been companies like your in the past that have screwed people over and disapeared over night because they thought there product would hold up without any acual testing. 12 tons on a shop press means nothing. Try some real driving for your testing.

ChadCrissDesign

+1y

--------------------------------------------

ahab said:

Your product is terrible and your attitude is worse. Even if you could figure out a way to make this setup stay together I doubt anyone would buy it from you. You are a "know it all" with very little experiance. Regarless of what welder you use, you should be able to weld good if you are a good welder. That is a lame excuse. The upper arm bushing attachment looks like a fail point. Another thing is, before you get on a website and start talking about selling your stuff you should really put some miles on your product before you even consider marketing, or producing it for the public. There have been companies like your in the past that have screwed people over and disapeared over night because they thought there product would hold up without any acual testing. 12 tons on a shop press means nothing. Try some real driving for your testing.

--------------------------------------------

lol this shit is never ending. I get good info from someone, thank him and all I get is more people talking shit. good times.

ahab said:

Your product is terrible and your attitude is worse. Even if you could figure out a way to make this setup stay together I doubt anyone would buy it from you. You are a "know it all" with very little experiance. Regarless of what welder you use, you should be able to weld good if you are a good welder. That is a lame excuse. The upper arm bushing attachment looks like a fail point. Another thing is, before you get on a website and start talking about selling your stuff you should really put some miles on your product before you even consider marketing, or producing it for the public. There have been companies like your in the past that have screwed people over and disapeared over night because they thought there product would hold up without any acual testing. 12 tons on a shop press means nothing. Try some real driving for your testing.

--------------------------------------------

lol this shit is never ending. I get good info from someone, thank him and all I get is more people talking shit. good times.

low_blazer

+1y

Honestly, even if you overlook the quality of the welds, there are several serious structural issues with the design. The lower control arms will fail...period. If you're redesigning them that's cool...but those ones would not survive a run up I-5. You would be surprised how much force is imparted on the lower control arm...especially out toward the balljoint.

The upper control arm mounts need more support. The gussets look nice, but they're not going to do you any good. A good portion of the forces on those upper mounts are torsional. Every time you hit a bump, not only are the control arms moving up and down, but they're trying to twist front to back. Those upper mounts are too close together to provide a solid base for the upper arms...

Lower control arm mounts...kinda the same thing. Your gusset work on the rear a-arm mount in facing the wrong direction....Vertical gussets do no good on something where the forces presented are mostly coming in horizontally.

And, honestly, with everything else being custom cut, why did you retain the stock crossmember under the engine?

The only thing saving the lack of engineering is material thickness....but even 1/4" plate will fatigue and fail around poor welds...

I can apreciate what you're trying to do, and if you're going for pure aesthetics, that's great...if redesigned, it could be a cool looking kit. Unfortunately, what you're doing can be acomplished with tubular arms, or stock arms, and spindles.

That's about as close to constructive criticism as I could get...

The upper control arm mounts need more support. The gussets look nice, but they're not going to do you any good. A good portion of the forces on those upper mounts are torsional. Every time you hit a bump, not only are the control arms moving up and down, but they're trying to twist front to back. Those upper mounts are too close together to provide a solid base for the upper arms...

Lower control arm mounts...kinda the same thing. Your gusset work on the rear a-arm mount in facing the wrong direction....Vertical gussets do no good on something where the forces presented are mostly coming in horizontally.

And, honestly, with everything else being custom cut, why did you retain the stock crossmember under the engine?

The only thing saving the lack of engineering is material thickness....but even 1/4" plate will fatigue and fail around poor welds...

I can apreciate what you're trying to do, and if you're going for pure aesthetics, that's great...if redesigned, it could be a cool looking kit. Unfortunately, what you're doing can be acomplished with tubular arms, or stock arms, and spindles.

That's about as close to constructive criticism as I could get...

ChadCrissDesign

+1y

--------------------------------------------

low blazer said:

Honestly, even if you overlook the quality of the welds, there are several serious structural issues with the design. The lower control arms will fail...period. If you're redesigning them that's cool...but those ones would not survive a run up I-5. You would be surprised how much force is imparted on the lower control arm...especially out toward the balljoint.

The upper control arm mounts need more support. The gussets look nice, but they're not going to do you any good. A good portion of the forces on those upper mounts are torsional. Every time you hit a bump, not only are the control arms moving up and down, but they're trying to twist front to back. Those upper mounts are too close together to provide a solid base for the upper arms...

Lower control arm mounts...kinda the same thing. Your gusset work on the rear a-arm mount in facing the wrong direction....Vertical gussets do no good on something where the forces presented are mostly coming in horizontally.

And, honestly, with everything else being custom cut, why did you retain the stock crossmember under the engine?

The only thing saving the lack of engineering is material thickness....but even 1/4" plate will fatigue and fail around poor welds...

I can apreciate what you're trying to do, and if you're going for pure aesthetics, that's great...if redesigned, it could be a cool looking kit. Unfortunately, what you're doing can be acomplished with tubular arms, or stock arms, and spindles.

That's about as close to constructive criticism as I could get...

--------------------------------------------

Thanks bro, Ya i was looking at the gussets the other day and was thinking the same thing. Your right. Ive been reading alot of max fish's work and im going to redesign this thing alittle. Im going to move the a-arm back were its saposed to go so that the roll center is back corrected. I making the lower a-arms with full length gussets front to back so that will increase strength a ton. The a-arm mounts are DOM, the same as what artmorrison uses on his hot rods so I think thats ok to keep, same as the bushings. As for the crossmember, I havn't even thought about that thing yet. I figured, you can hardly see it, and the stock one works fine I guess lol. I might get to that later. My main thing with this was how easy it is to install, If your frame was bare in the front, your looking at fully front bagged in 3 hours or less. Ill have more updates soon. Thanks again.

low blazer said:

Honestly, even if you overlook the quality of the welds, there are several serious structural issues with the design. The lower control arms will fail...period. If you're redesigning them that's cool...but those ones would not survive a run up I-5. You would be surprised how much force is imparted on the lower control arm...especially out toward the balljoint.

The upper control arm mounts need more support. The gussets look nice, but they're not going to do you any good. A good portion of the forces on those upper mounts are torsional. Every time you hit a bump, not only are the control arms moving up and down, but they're trying to twist front to back. Those upper mounts are too close together to provide a solid base for the upper arms...

Lower control arm mounts...kinda the same thing. Your gusset work on the rear a-arm mount in facing the wrong direction....Vertical gussets do no good on something where the forces presented are mostly coming in horizontally.

And, honestly, with everything else being custom cut, why did you retain the stock crossmember under the engine?

The only thing saving the lack of engineering is material thickness....but even 1/4" plate will fatigue and fail around poor welds...

I can apreciate what you're trying to do, and if you're going for pure aesthetics, that's great...if redesigned, it could be a cool looking kit. Unfortunately, what you're doing can be acomplished with tubular arms, or stock arms, and spindles.

That's about as close to constructive criticism as I could get...

--------------------------------------------

Thanks bro, Ya i was looking at the gussets the other day and was thinking the same thing. Your right. Ive been reading alot of max fish's work and im going to redesign this thing alittle. Im going to move the a-arm back were its saposed to go so that the roll center is back corrected. I making the lower a-arms with full length gussets front to back so that will increase strength a ton. The a-arm mounts are DOM, the same as what artmorrison uses on his hot rods so I think thats ok to keep, same as the bushings. As for the crossmember, I havn't even thought about that thing yet. I figured, you can hardly see it, and the stock one works fine I guess lol. I might get to that later. My main thing with this was how easy it is to install, If your frame was bare in the front, your looking at fully front bagged in 3 hours or less. Ill have more updates soon. Thanks again.

X

xgolferdude

+1y

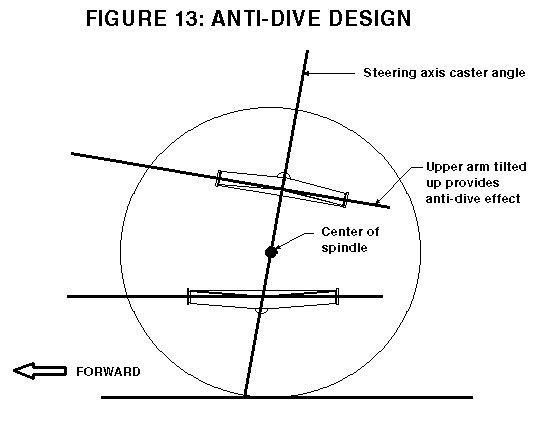

now when you set up for anti dive, is that mainly just having the uppers angled back 3-5% away from the front of the truck? I wasnt sure.. Thanks.. sorry for the thread hijack....

low_blazer

+1y

That's an easy way to do it...the goal is to have the control arm instant center somewhere behind the front wheel, and above the ground...

Related Discussions in Air Ride Suspensions

Thread

Posts

Last Post