turbo V8, ultimate b2200 conversion, "Stranger". Final pics

94660 views

399 replies

51 following

turbo V8, ultimate b2200 conversion, "Stranger". Final pics

mtrain

+1y

Well, the next step is to get some friends over to help move the bed so that I can get the truck loaded onto my trailer go have the front end aligned.

Then the bed can be installed, and painted, then maybe I can finally get some good pics, and drive the truck down the road.

Then the bed can be installed, and painted, then maybe I can finally get some good pics, and drive the truck down the road.

mtrain

+1y

Ok, well I finally got it pulled out today. It bottomed out HARD on a small concrete bump I have under the grass going to the driveway.

The rear wheels are really going to be a problem as this thing obliterates them with only a blip of the throttle.

I didn't take a shot of the side or rear of the truck as I think it looks kinda ugly without the bed.

The rear wheels are really going to be a problem as this thing obliterates them with only a blip of the throttle.

I didn't take a shot of the side or rear of the truck as I think it looks kinda ugly without the bed.

B

bratliff

+1y

Looks good m train.. we need video of the craziness.. btw.. front end looks good.

paparoach1983

+1y

Yeah nice conversion man. Looks good.

mtrain

+1y

Now for more fun/setback/divorce/etc. As you might well expect my little wife is really starting to hate this truck. I still haven't told her about the wasted R12.

But today I took the truck to the alignment shop, and I picked this guy for two reasons, 1. I have known him for quite a few years, and have developed a friendship, and 2, he builds rock crawler trucks for a hobby.

The whole shop as well as a few people in the parking lot came around to check out the truck after getting it off the trailer. The alignment guy, we'll call him Bob, said that just by looking at it there was waaaaay too much neg camber, and no way to get the upper arm out any longer.

NOTE, these upper,and lower arms came from Dallas Hot Rod, so take that for what is worth. I have done NOTHING to change the mounting point of this front suspension either, so the arms should have had some adjustment, like a rod end setup.

Anyway we talked some more, and then I loaded up the truck and headed for home. I got a brilliant idea. I could level up the steel trailer, then find the camber with my camber gauge. So that is what I did.

I put a block of wood and some steel shims until I contacted the lower control arm. Then I jacked up the truck and pulled the wheel/tire.

I set the gauge on the brake disc with the gauge magnet, and after some adjustment took some readings.

With one factory shim the camber was 2.5 neg. Removing that shim put it at 1 3/4.

So I took the upper arm off which was quite fun as I literally had to take it all apart since it wouldn't clear the shockwave shock {which would have been even more fun to take off.}

I took the attachment bar over to my vice and clamped it down. I ground the bar flush with the mounting holes, and measured with my calipers for the other upper arm.

Went back to the truck, put it all back together, but just before tightening everything down I thought I would check jut to make sure the attachment bar was sitting flush.

IT WAS NOT. There was still a full shim space open. I pulled the arm back to see that there is an angle going up to the mounting spot that was keeping the arm from going all the way down.

Now I have the arm back off, and am going to grind off an angle of the arm so that it should set flush. I'm too wore out to finish, and I know my wife is going to scream when she gets home, and see's the truck even more disassembled than before.

Update: I was able to get the neg camber down to 1/2 deg neg at ride height.

This is about right as I can easily change the neg camber for autocross, or road race just by lowering my ride height with the Shock Wave shocks.

But today I took the truck to the alignment shop, and I picked this guy for two reasons, 1. I have known him for quite a few years, and have developed a friendship, and 2, he builds rock crawler trucks for a hobby.

The whole shop as well as a few people in the parking lot came around to check out the truck after getting it off the trailer. The alignment guy, we'll call him Bob, said that just by looking at it there was waaaaay too much neg camber, and no way to get the upper arm out any longer.

NOTE, these upper,and lower arms came from Dallas Hot Rod, so take that for what is worth. I have done NOTHING to change the mounting point of this front suspension either, so the arms should have had some adjustment, like a rod end setup.

Anyway we talked some more, and then I loaded up the truck and headed for home. I got a brilliant idea. I could level up the steel trailer, then find the camber with my camber gauge. So that is what I did.

I put a block of wood and some steel shims until I contacted the lower control arm. Then I jacked up the truck and pulled the wheel/tire.

I set the gauge on the brake disc with the gauge magnet, and after some adjustment took some readings.

With one factory shim the camber was 2.5 neg. Removing that shim put it at 1 3/4.

So I took the upper arm off which was quite fun as I literally had to take it all apart since it wouldn't clear the shockwave shock {which would have been even more fun to take off.}

I took the attachment bar over to my vice and clamped it down. I ground the bar flush with the mounting holes, and measured with my calipers for the other upper arm.

Went back to the truck, put it all back together, but just before tightening everything down I thought I would check jut to make sure the attachment bar was sitting flush.

IT WAS NOT. There was still a full shim space open. I pulled the arm back to see that there is an angle going up to the mounting spot that was keeping the arm from going all the way down.

Now I have the arm back off, and am going to grind off an angle of the arm so that it should set flush. I'm too wore out to finish, and I know my wife is going to scream when she gets home, and see's the truck even more disassembled than before.

Update: I was able to get the neg camber down to 1/2 deg neg at ride height.

This is about right as I can easily change the neg camber for autocross, or road race just by lowering my ride height with the Shock Wave shocks.

mtrain

+1y

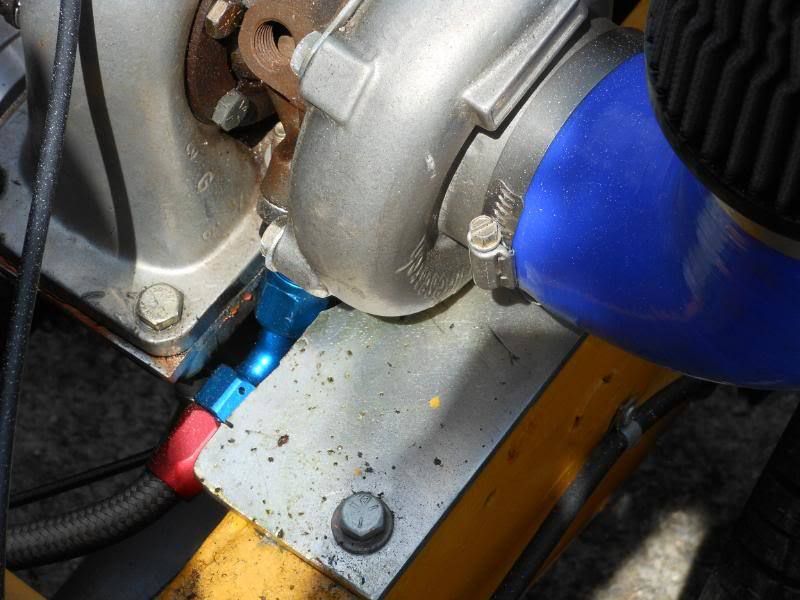

Well, I made it back to the alignment shop yesterday, and was finally able to get everything straight.....TG!

There was one problem with the driverside Shockwave air shock. It was leaking air. I feared the worse as I had to remove some metal that was touching the rubber bellows of the shock, and feared that I might have nicked something.

So today I pulled the front wheel, and changed the air fitting with a new one, and trimmed the push in line about an inch.

Now she is back to sitting level again. Hopefully I can driver her soon.

There was one problem with the driverside Shockwave air shock. It was leaking air. I feared the worse as I had to remove some metal that was touching the rubber bellows of the shock, and feared that I might have nicked something.

So today I pulled the front wheel, and changed the air fitting with a new one, and trimmed the push in line about an inch.

Now she is back to sitting level again. Hopefully I can driver her soon.

immortal1 (linn)

+1y

Congratz on getting it aligned- finally. Was wondering when I would see the next update

mtrain

+1y

Thanks IM, I'm happy as well.

Let me ask you guys who fab your own 4 links, etc.

The alignment guy {who also builds rock crawlers} said that my upper control arms on the rear end needed some mis-alignment washers.

He said my current setup would still allow movement. What I have is a bushing, and two cone spacers like these.

What I did when I got home was to cut the bushing down to where the cone spacer didn't allow back and forth movement.

Will this be acceptable over buying mis-alignment washers?

Let me ask you guys who fab your own 4 links, etc.

The alignment guy {who also builds rock crawlers} said that my upper control arms on the rear end needed some mis-alignment washers.

He said my current setup would still allow movement. What I have is a bushing, and two cone spacers like these.

What I did when I got home was to cut the bushing down to where the cone spacer didn't allow back and forth movement.

Will this be acceptable over buying mis-alignment washers?

paparoach1983

+1y

I would say post a pic of what you want to do so we can take a look

mtrain

+1y

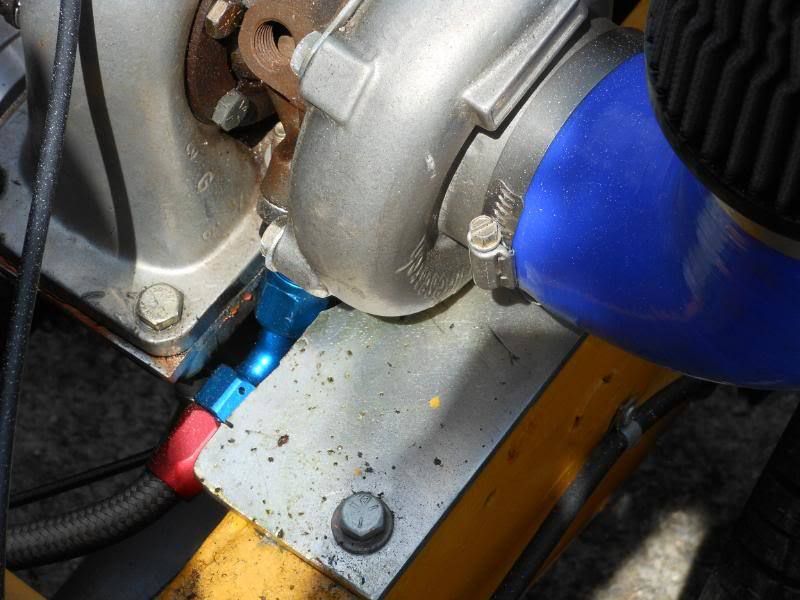

On the advise of Madarati I bought some flex joints to keep my exhaust, or worse one of the turbo housings, from cracking. The reason is that the turbo's are mounted to the frame to secure them, but I couldn't figure out how to build some give into the pipes until Mazdarati gave me the suggestion {thanks again}.

I finally got around to doing it today. I spent about half of the d*mned day trying to find the new welding wire that I had just bought, well it was right on my bench in plain view.

So I decided while I was at it to put a v-band clamp on one of my H-pipes running under the car as I had one that I bought which was the wrong size at the time.

I was only able to get one done as it started to storm, so I will try to finish tomorrow.

I finally got around to doing it today. I spent about half of the d*mned day trying to find the new welding wire that I had just bought, well it was right on my bench in plain view.

So I decided while I was at it to put a v-band clamp on one of my H-pipes running under the car as I had one that I bought which was the wrong size at the time.

I was only able to get one done as it started to storm, so I will try to finish tomorrow.

Related Discussions in Mazda Projects

Thread

Posts

Last Post

852

last post by

skrapinsask +1y

150

last post by

cherokeed +1y