S

Dallas Hotrod Parts?

zms2004

+1y

like i said months ago in this thread, i bought parts off of mike, i never dealt with byc, but was willing to give him a chance. i got my isuzu upper arms and they looked fine. i would have ordered a set of lowers, if i hadnt junked the truck. would i order from him again, sure. why not. i think alot of the problems on here are people commenting that arent customers of DHP, im assuming they are either angry byc customers or not customers at all. i do believe mike is tryin to straighten things out, i had a problem with my order, it was promptly fixed. and it was a small issue. i received the wrong ball joints. he shipped the correct ones out that day without a problem. i dont truly believe that i was one of the FEW that had good experiences with him. ive bought parts from suicidedoors, MMW, silverstar customs, fbi, alot of big name companies, and yea, the parts from the big companies may be tig welded, or just a little more quality, but for what the guy is working with, i give him credit. to be honest, i have fbi lower control arms on my frame right now, i had to cut the shit out of em to get em to fit properly. they are mig welded, and i really dont like the balljoint cup on them, so im considerin replacing the cup. every company has flaws somewhere, some are just bigger than others.

unusualfabrication

+1y

--------------------------------------------

Low_SSTFor your balljoint to fall out it would need to pull straight through, past the shoulder on the cup and bj.

[/quote said:

That could happen if it were a two piece cup with the 2 pieces of tubing telescoped together and welded. If the weld on the end, fusing the two pieces together, failed the inside piece and balljoint would slide right out. I'm not sure how Mike made the 2-piece cups but thats really the only way I could see it.

Low_SSTFor your balljoint to fall out it would need to pull straight through, past the shoulder on the cup and bj.

[/quote said:

That could happen if it were a two piece cup with the 2 pieces of tubing telescoped together and welded. If the weld on the end, fusing the two pieces together, failed the inside piece and balljoint would slide right out. I'm not sure how Mike made the 2-piece cups but thats really the only way I could see it.

O

olskoolpup

+1y

Edited: 10/23/2010 5:28:21 PM by 86IsuzuPup

--------------------------------------------

fabricationnation said:

--------------------------------------------

86IsuzuPup said:

Mike whats up man? I ordered a set of upper and lower control arms from you roughly 5 years ago for my 86 Isuzu Pup! I was wondering if they made it in the mail last week? or maybe in a day or two? what were the other lines you fed me for weeks and months? better yet, keep my $350, you obviously need it more than I do....

Bryan

--------------------------------------------

This is the kind of smart ass crap not needed here. Ive had posts in forums and on my website since January of 2008.

If you really had an order you need to get in touch with me. However I suspect this is an attempt at jumping on the bandwagon. This is the reason I dont even want to post in here. nothing constructive at all, just people who know nothing about me or my situation trying to get in a jab or jump on the bandwagon.

I think everything has been covered here, asked and answered and now its time to move on. Unless theres something useful...

--------------------------------------------

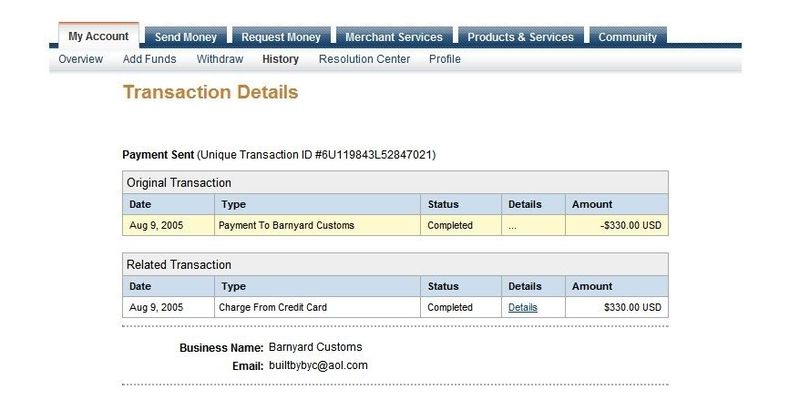

Bandwagon huh? I'm on my own wagon bro! Should have thought of that before you screwed so many people. See Paypal receipt below dated Aug 9 2005 for $330 (sorry it had been so long my figures were off)

Feel free to "do the right thing", ie, credit my account or send me some butt welded, DOM, half assed paper weights...your choice

After getting my degree in ME since my order and seeing your recent products, I wouldn't use them on a wheel barrow...

--------------------------------------------

fabricationnation said:

--------------------------------------------

86IsuzuPup said:

Mike whats up man? I ordered a set of upper and lower control arms from you roughly 5 years ago for my 86 Isuzu Pup! I was wondering if they made it in the mail last week? or maybe in a day or two? what were the other lines you fed me for weeks and months? better yet, keep my $350, you obviously need it more than I do....

Bryan

--------------------------------------------

This is the kind of smart ass crap not needed here. Ive had posts in forums and on my website since January of 2008.

If you really had an order you need to get in touch with me. However I suspect this is an attempt at jumping on the bandwagon. This is the reason I dont even want to post in here. nothing constructive at all, just people who know nothing about me or my situation trying to get in a jab or jump on the bandwagon.

I think everything has been covered here, asked and answered and now its time to move on. Unless theres something useful...

--------------------------------------------

Bandwagon huh? I'm on my own wagon bro! Should have thought of that before you screwed so many people. See Paypal receipt below dated Aug 9 2005 for $330 (sorry it had been so long my figures were off)

Feel free to "do the right thing", ie, credit my account or send me some butt welded, DOM, half assed paper weights...your choice

After getting my degree in ME since my order and seeing your recent products, I wouldn't use them on a wheel barrow...

thacru78

+1y

So your making and shipping new parts out right now!! But have yet to make and ship orders from 5 years back. I don't see how that is a good business practice. I believe in second chances...which is why I've taken up for you in the past. My advice is to man up and make ur past orders current before making any new orders. I've built several sets of arms...and material cost is not so high that you can't make a few sets and ship them to ur customers that you still owe. Just my .02

T

toreadorxlt

+1y

Edited: 10/24/2010 12:13:52 AM by toreadorxlt

--------------------------------------------

Chopped Mazda said:

That balljoint posted earlier, with the strategically placed "grooves" , is that a one piece or two piece cup?

I think his problem was with the poor machining quality on the cup, rather than it being two pieces.

Taylor

--------------------------------------------

--------------------------------------------

UnusualFabrication said:

Mike, can you prove that these grooves help the balljoints cups? I would think that by grooving the inside where the balljoint seats on the cup that you are reducing surface area for the press fit. I use S-10 press-in lower balljoints in my Mazda lower tube arms and also in my S-10 lower tube arms and have never had a balljoint come loose or fallout.

--------------------------------------------

He's joking himself... I'm the lucky guy that owns the box of shit parts..

I have a college degree in product design, I do quality engineering and technical design for a living. I scratch built my own cups on a lathe... I own a lathe. He's a fucking joke if he thinks that hes pulling the wool over my eyes with his excuses for the pictures I posted up. I'm have the parts in the pictures in my possession... They are .025" undersized where in the worse case the balljoint would slip out the bottom. The pattern is so sporadic, that the only excuse is poor machining. I promise you it can't be duplicated. I challenge him to duplicate this shit. As far as TIG welded, thats a joke. Everything I recieved was MIG welded.

--------------------------------------------

havok said:

I have bought many sets of arms from mike, and most of them were "custom" orders. Mazda arms with toy ball joints, 1-ton chevy arms that are shorter than factory and longer than factory, etc and so far they all have worked and done the job. They look strong and has kept all the vehicles off the ground with no problems. If time is a issue you may have to go somewhere else. Price is always good and the functionality has been fine. I have ordered arms from AIM, and Air ride tech and have issues with both of them. Just today I had to reweld some Air Ride Tech "strong arms" that broke a bag plate weld. His arms are great for 99% of us minitruckers. It would be nice if we could get them quicker like a mass produced arm, but I don't think that will happen, way to many variables.

Does a funky hole from a plasma cut hole affect the way your vehicle ride? NoDoes ridges on your ball joint cup affect the way your vehicle ride, or if it started life as 2 parts? No

Could have parts been made better? YesCould you have had the part sooner? YesCould you have paid more? Yes

Could I be a porn star? YesWould anyone watch? No

Just my couple of cents.....

--------------------------------------------

I never complained about the 2 part balljoint cup, infact it makes total sense. But what about the shitty machining? What are your comments on the cup being ovalized? Or the useless rod ends i received. This is after saying the parts would take 5-7 days to make on 11/14/09, and I received them on 1/29/10...

--------------------------------------------

Chopped Mazda said:

That balljoint posted earlier, with the strategically placed "grooves" , is that a one piece or two piece cup?

I think his problem was with the poor machining quality on the cup, rather than it being two pieces.

Taylor

--------------------------------------------

--------------------------------------------

UnusualFabrication said:

Mike, can you prove that these grooves help the balljoints cups? I would think that by grooving the inside where the balljoint seats on the cup that you are reducing surface area for the press fit. I use S-10 press-in lower balljoints in my Mazda lower tube arms and also in my S-10 lower tube arms and have never had a balljoint come loose or fallout.

--------------------------------------------

He's joking himself... I'm the lucky guy that owns the box of shit parts..

I have a college degree in product design, I do quality engineering and technical design for a living. I scratch built my own cups on a lathe... I own a lathe. He's a fucking joke if he thinks that hes pulling the wool over my eyes with his excuses for the pictures I posted up. I'm have the parts in the pictures in my possession... They are .025" undersized where in the worse case the balljoint would slip out the bottom. The pattern is so sporadic, that the only excuse is poor machining. I promise you it can't be duplicated. I challenge him to duplicate this shit. As far as TIG welded, thats a joke. Everything I recieved was MIG welded.

--------------------------------------------

havok said:

I have bought many sets of arms from mike, and most of them were "custom" orders. Mazda arms with toy ball joints, 1-ton chevy arms that are shorter than factory and longer than factory, etc and so far they all have worked and done the job. They look strong and has kept all the vehicles off the ground with no problems. If time is a issue you may have to go somewhere else. Price is always good and the functionality has been fine. I have ordered arms from AIM, and Air ride tech and have issues with both of them. Just today I had to reweld some Air Ride Tech "strong arms" that broke a bag plate weld. His arms are great for 99% of us minitruckers. It would be nice if we could get them quicker like a mass produced arm, but I don't think that will happen, way to many variables.

Does a funky hole from a plasma cut hole affect the way your vehicle ride? NoDoes ridges on your ball joint cup affect the way your vehicle ride, or if it started life as 2 parts? No

Could have parts been made better? YesCould you have had the part sooner? YesCould you have paid more? Yes

Could I be a porn star? YesWould anyone watch? No

Just my couple of cents.....

--------------------------------------------

I never complained about the 2 part balljoint cup, infact it makes total sense. But what about the shitty machining? What are your comments on the cup being ovalized? Or the useless rod ends i received. This is after saying the parts would take 5-7 days to make on 11/14/09, and I received them on 1/29/10...

F

fabricationnation

+1y

--------------------------------------------

UnusualFabrication said:

Mike, can you prove that these grooves help the balljoints cups? I would think that by grooving the inside where the balljoint seats on the cup that you are reducing surface area for the press fit. I use S-10 press-in lower balljoints in my Mazda lower tube arms and also in my S-10 lower tube arms and have never had a balljoint come loose or fallout.

--------------------------------------------

prove it? are you kidding me?

most balljoints come with grooves, and they dont lessen the grip they improve it.

smooth balljoints are designed by the manufacturer to go into a stamped steel control arm. after a while the tightness of the arm is lessened and the aftermarket balljoints have grooves to improve the tightness and fit. This is obvious to anyone who has pressed in alot of aftermarket balljoints.

Ive never had one come out either, that does not prove anything other than we have gotten the tightness correct.

The ones that are grooved now have smaller sharper grooves rather than the larger deeper grooves I used to make.

I have seen arms used for testing that have had the balljoints pressed in an out several times get looser every time and the grooves improve that.

UnusualFabrication said:

Mike, can you prove that these grooves help the balljoints cups? I would think that by grooving the inside where the balljoint seats on the cup that you are reducing surface area for the press fit. I use S-10 press-in lower balljoints in my Mazda lower tube arms and also in my S-10 lower tube arms and have never had a balljoint come loose or fallout.

--------------------------------------------

prove it? are you kidding me?

most balljoints come with grooves, and they dont lessen the grip they improve it.

smooth balljoints are designed by the manufacturer to go into a stamped steel control arm. after a while the tightness of the arm is lessened and the aftermarket balljoints have grooves to improve the tightness and fit. This is obvious to anyone who has pressed in alot of aftermarket balljoints.

Ive never had one come out either, that does not prove anything other than we have gotten the tightness correct.

The ones that are grooved now have smaller sharper grooves rather than the larger deeper grooves I used to make.

I have seen arms used for testing that have had the balljoints pressed in an out several times get looser every time and the grooves improve that.

F

fabricationnation

+1y

--------------------------------------------

UnusualFabrication said:

--------------------------------------------

Low_SSTFor your balljoint to fall out it would need to pull straight through, past the shoulder on the cup and bj.

[/quote said:

That could happen if it were a two piece cup with the 2 pieces of tubing telescoped together and welded. If the weld on the end, fusing the two pieces together, failed the inside piece and balljoint would slide right out. I'm not sure how Mike made the 2-piece cups but thats really the only way I could see it.

--------------------------------------------

Yes thats how I made them. The reason was to standardize the size of the outer tube to make it more compatible on the jig.

I changed the way all my balljoint cups are held in the jig to solve this. I now use a bolt in the center with a round solid slug with the proper size groove.

Im nut dumb guys I just make so many different arms with so many balljoint choices that it was what worked at the time. The new single bolt allows me to use any size tube and its centered by the slug.

Ive never had a balljoint cup fail or get loose and we are talking literally hundreds of sets of arms going back to 1998 on customer parts and way farther back on my own parts.

the newer ones I make now the sharper grooves feel more like sandpaper than grooves.

this issue is solved, been discussed, answered and talked about from all angles. you guys have asked the same question from several different points of view and Ive answered with credible reasons why I did what I did. The balljoint cups performed very well. The issue was when they are tig welded together they leave grooves from the "dig" of the weld and I did not machine down past that. plus the grooves were not attractive to the customer.

UnusualFabrication said:

--------------------------------------------

Low_SSTFor your balljoint to fall out it would need to pull straight through, past the shoulder on the cup and bj.

[/quote said:

That could happen if it were a two piece cup with the 2 pieces of tubing telescoped together and welded. If the weld on the end, fusing the two pieces together, failed the inside piece and balljoint would slide right out. I'm not sure how Mike made the 2-piece cups but thats really the only way I could see it.

--------------------------------------------

Yes thats how I made them. The reason was to standardize the size of the outer tube to make it more compatible on the jig.

I changed the way all my balljoint cups are held in the jig to solve this. I now use a bolt in the center with a round solid slug with the proper size groove.

Im nut dumb guys I just make so many different arms with so many balljoint choices that it was what worked at the time. The new single bolt allows me to use any size tube and its centered by the slug.

Ive never had a balljoint cup fail or get loose and we are talking literally hundreds of sets of arms going back to 1998 on customer parts and way farther back on my own parts.

the newer ones I make now the sharper grooves feel more like sandpaper than grooves.

this issue is solved, been discussed, answered and talked about from all angles. you guys have asked the same question from several different points of view and Ive answered with credible reasons why I did what I did. The balljoint cups performed very well. The issue was when they are tig welded together they leave grooves from the "dig" of the weld and I did not machine down past that. plus the grooves were not attractive to the customer.

unusualfabrication

+1y

--------------------------------------------

fabricationnation said:

--------------------------------------------

UnusualFabrication said:

Mike, can you prove that these grooves help the balljoints cups? I would think that by grooving the inside where the balljoint seats on the cup that you are reducing surface area for the press fit. I use S-10 press-in lower balljoints in my Mazda lower tube arms and also in my S-10 lower tube arms and have never had a balljoint come loose or fallout.

--------------------------------------------

prove it? are you kidding me?

most balljoints come with grooves, and they dont lessen the grip they improve it.

smooth balljoints are designed by the manufacturer to go into a stamped steel control arm. after a while the tightness of the arm is lessened and the aftermarket balljoints have grooves to improve the tightness and fit. This is obvious to anyone who has pressed in alot of aftermarket balljoints.

Ive never had one come out either, that does not prove anything other than we have gotten the tightness correct.

The ones that are grooved now have smaller sharper grooves rather than the larger deeper grooves I used to make.

I have seen arms used for testing that have had the balljoints pressed in an out several times get looser every time and the grooves improve that.

--------------------------------------------

Wierd, I have no less than 3 sets of aftermarket balljoints out in the shop and none of them have grooves in them. I have two sets of stock S-10 lowers and guess what, no grooves in the factory stampings. Yes prove it! They sell oversized aftermarket balljoints that are identical to the factory balljoints except the casing is oversized .010' or more. Maybe if you brushed that chip off your shoulder you might get a warmer reception from people. Begining you replied with "prove it? Are you kidding me?", like your so much smarter than everybody else. The fact is that you have nothing to back up the claim that these "grooves" help or hinder anything. The reason the balljoints gets loose after pressing them in and out alot is because the metal cup or stock stamping stretches. No matter how many grooves you put in the cup it doesn't mean shit if it is stretching out.

fabricationnation said:

--------------------------------------------

UnusualFabrication said:

Mike, can you prove that these grooves help the balljoints cups? I would think that by grooving the inside where the balljoint seats on the cup that you are reducing surface area for the press fit. I use S-10 press-in lower balljoints in my Mazda lower tube arms and also in my S-10 lower tube arms and have never had a balljoint come loose or fallout.

--------------------------------------------

prove it? are you kidding me?

most balljoints come with grooves, and they dont lessen the grip they improve it.

smooth balljoints are designed by the manufacturer to go into a stamped steel control arm. after a while the tightness of the arm is lessened and the aftermarket balljoints have grooves to improve the tightness and fit. This is obvious to anyone who has pressed in alot of aftermarket balljoints.

Ive never had one come out either, that does not prove anything other than we have gotten the tightness correct.

The ones that are grooved now have smaller sharper grooves rather than the larger deeper grooves I used to make.

I have seen arms used for testing that have had the balljoints pressed in an out several times get looser every time and the grooves improve that.

--------------------------------------------

Wierd, I have no less than 3 sets of aftermarket balljoints out in the shop and none of them have grooves in them. I have two sets of stock S-10 lowers and guess what, no grooves in the factory stampings. Yes prove it! They sell oversized aftermarket balljoints that are identical to the factory balljoints except the casing is oversized .010' or more. Maybe if you brushed that chip off your shoulder you might get a warmer reception from people. Begining you replied with "prove it? Are you kidding me?", like your so much smarter than everybody else. The fact is that you have nothing to back up the claim that these "grooves" help or hinder anything. The reason the balljoints gets loose after pressing them in and out alot is because the metal cup or stock stamping stretches. No matter how many grooves you put in the cup it doesn't mean shit if it is stretching out.

F

fabricationnation

+1y

--------------------------------------------

thacru78 said:

So your making and shipping new parts out right now!! But have yet to make and ship orders from 5 years back. I don't see how that is a good business practice. I believe in second chances...which is why I've taken up for you in the past. My advice is to man up and make ur past orders current before making any new orders. I've built several sets of arms...and material cost is not so high that you can't make a few sets and ship them to ur customers that you still owe. Just my .02

--------------------------------------------

have you not been reading the thread?? "have yet to ship orders from 5 years back"

I have been shipping old orders. I have to have funds coming in to build them with. is that not obvious?

your advice wont work in this situation. I have a fulltime job and a family to support. I have kids and get no child support from their mother.

I have to sell arms to pay for materials for other arms. as I said I have been sending out old orders.

Im glad you have made several sets, this shows that you know how difficult it is. But understand building them in a production format is way different. I have built several sets also, several hundred sets with absolutely no issues and happy owners.

I also built several sets this past couple weeks.

did I say I cant make sets to customers I still owe?? no, never said that. so please go back and read the thread and see what Ive posted and you will see that I started January 2008 with nothing and had no loans, help or anything and had to sue my ex to get my kids living with me and get housing for them and myself and I still worked 60 hours a week to make it where I could start making old orders.

If I had to save money and buy equipment to build old orders first I would have taken much longer to get the equipment.

If I had just started sending extra money to old orders it would also have taken longer. you dont think I thought this through? I had 20 months to think it through and make a plan.

the best and fastest way was to start making parts again. that way I get funds faster, make old orders faster and help new customers.

you see Im not in you guys shoes seeing this in posts in a forum, Im living it and I think about my business all day every day.

thacru78 said:

So your making and shipping new parts out right now!! But have yet to make and ship orders from 5 years back. I don't see how that is a good business practice. I believe in second chances...which is why I've taken up for you in the past. My advice is to man up and make ur past orders current before making any new orders. I've built several sets of arms...and material cost is not so high that you can't make a few sets and ship them to ur customers that you still owe. Just my .02

--------------------------------------------

have you not been reading the thread?? "have yet to ship orders from 5 years back"

I have been shipping old orders. I have to have funds coming in to build them with. is that not obvious?

your advice wont work in this situation. I have a fulltime job and a family to support. I have kids and get no child support from their mother.

I have to sell arms to pay for materials for other arms. as I said I have been sending out old orders.

Im glad you have made several sets, this shows that you know how difficult it is. But understand building them in a production format is way different. I have built several sets also, several hundred sets with absolutely no issues and happy owners.

I also built several sets this past couple weeks.

did I say I cant make sets to customers I still owe?? no, never said that. so please go back and read the thread and see what Ive posted and you will see that I started January 2008 with nothing and had no loans, help or anything and had to sue my ex to get my kids living with me and get housing for them and myself and I still worked 60 hours a week to make it where I could start making old orders.

If I had to save money and buy equipment to build old orders first I would have taken much longer to get the equipment.

If I had just started sending extra money to old orders it would also have taken longer. you dont think I thought this through? I had 20 months to think it through and make a plan.

the best and fastest way was to start making parts again. that way I get funds faster, make old orders faster and help new customers.

you see Im not in you guys shoes seeing this in posts in a forum, Im living it and I think about my business all day every day.

F

fabricationnation

+1y

--------------------------------------------

86IsuzuPup said:

Bandwagon huh? I'm on my own wagon bro! Should have thought of that before you screwed so many people.

--------------------------------------------

Yea your jumping on the bandwagon instead of contacting me. you say I "screwed" people. you obviously did not read any posts. I went bankrupt and my shop was closed and I was locked out. I came back 20 months later JUST LIKE I SAID I WOULD and I have been making parts since.

how is that screwing anyone. My business grew too fast and I could not keep up selling parts too cheap to Jason and retail.

its as simple as that. Ive had the BYC page on my site since January of 2008 and if you havent seen any pf the threads here or any of the other forums where I regularly post then you must not have been reading any forums. if you have an old order then email me and lets get it worked out. You have not seen any of my new product so you really dont know. look at the pics on my website.

another incorrect posting full of incorrect info, rumor and conjecture.

86IsuzuPup said:

Bandwagon huh? I'm on my own wagon bro! Should have thought of that before you screwed so many people.

--------------------------------------------

Yea your jumping on the bandwagon instead of contacting me. you say I "screwed" people. you obviously did not read any posts. I went bankrupt and my shop was closed and I was locked out. I came back 20 months later JUST LIKE I SAID I WOULD and I have been making parts since.

how is that screwing anyone. My business grew too fast and I could not keep up selling parts too cheap to Jason and retail.

its as simple as that. Ive had the BYC page on my site since January of 2008 and if you havent seen any pf the threads here or any of the other forums where I regularly post then you must not have been reading any forums. if you have an old order then email me and lets get it worked out. You have not seen any of my new product so you really dont know. look at the pics on my website.

another incorrect posting full of incorrect info, rumor and conjecture.

Related Discussions in Mini Truckin General

Thread

Posts

Last Post