Using stock maz a/c compressor for edc

18985 views

125 replies

34 following

Using stock maz a/c compressor for edc

speedster93b

+1y

of course you need a relay between your compressor and your pressure switch.

dirtracer14

+1y

Ooppps I have been running it without for the last 4 months or so I have a 2 post relay for the fans i could use the other side for the pump..... Thanks,

speedster93b

+1y

WTF? 2 post relay?

alright, relays come in 4 or 5 terminals. two posts are for the 'low voltage side' and two(or 3) are for the 'high voltage side'

your switch (toggle, rocker, pressure switch, etc) will run thru the low voltage side, 12v in one and GD the other. when 12v is powered thru the relay on your low side(your switch is in the on position) it acts like an electromagnet pulling the contacts together for the high voltage side. the high voltage side of the relay will be what operates your compressor, fans, lights, etc. you'll have one post again with 12v going in, and the other side(if 4 terminal) going to your item needing electricity. most switches aren't designed to withstand all the current powering the compressor (or whatever) running thru them. relays on the otherhand are designed that way.

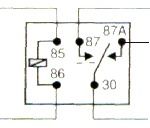

if its a 5 terminal relay, the low side is still the same, but the high side has ... uh, heres a pic.

85 and 86 are your low side

87 and 30 are your hi side and what you'd run your compressor or fans to.

87a would be constantly powered if your low side switch is in the off position. when the switch is flipped to on, power ceases at 87a, and switches to 87

hmm, i hope that wasn't too confusing.

i suppose i should say there are more than just 4 or 5 point relays, but they're more common to what we're doing....

majordrop

+1y

Excellent write up! This helped me out a lot due to the fact I had to redo my wiring (and nearly burnt out my 508 sandan). Got my wire, Relay, and this write up in hand.

And also thanks to Kaoss for showing the link to this thread...Thumbs up!

karathos

+1y

I know everyone has thier own theory on how the conversion should be done. I did mine by just tapping the outlets on the compressor, Wired the pressure switch from my tank directly to the clutch on my compressor. No relay, nothing, It draws so little voltage and amperage that there really is no reason for a relay. I also have NO oiler, NO dryer or any other kind of device to oil. I have been running my exact setup for 4 years now, As a daily driver and have never had any issues. I just make sure to check my oil level in the sump of the compressor every oil change.

Here are pics of my really really simple setup in my profile on Streetsource.

Here are pics of my really really simple setup in my profile on Streetsource.

majordrop

+1y

I did the same thing, But with the oiler

Related Discussions in Mazda Lowering Static

Thread

Posts

Last Post

12

L

last post by

Low5.0mazda +1y