PROJECT: Redemption (93 b2600i bagged and bodied)

105572 views

550 replies

91 following

PROJECT: Redemption (93 b2600i bagged and bodied)

bodied b2600zx (josh)

+1y

Here's the new welder. Miller 211. I got some welding done on the frame. Got the backhalf welded back on, some of the tabs welded in, and some grinding done. So far I love the welder. It's def a big step up from the Hobart 140. Ill be selling that one so I can buy more parts! Haha. And the second pic is the very first weld with the new welder. I had it on auto set for 1/4" with .035 sold core wire. Came out pretty good. Def pleased with the auto set feature.

vsawmike

+1y

The Hobart 140 is a good welder to start with but there are a few tips to make welds with it much better. Start by not using wire over .030 and it's even better with .023. Yes it takes more wire but with less heat needed to melt the wire the welder will heat the steel more. Grind a V shape into whatever you weld. The heat generated by filling the V will get you good penetration.

bodied b2600zx (josh)

+1y

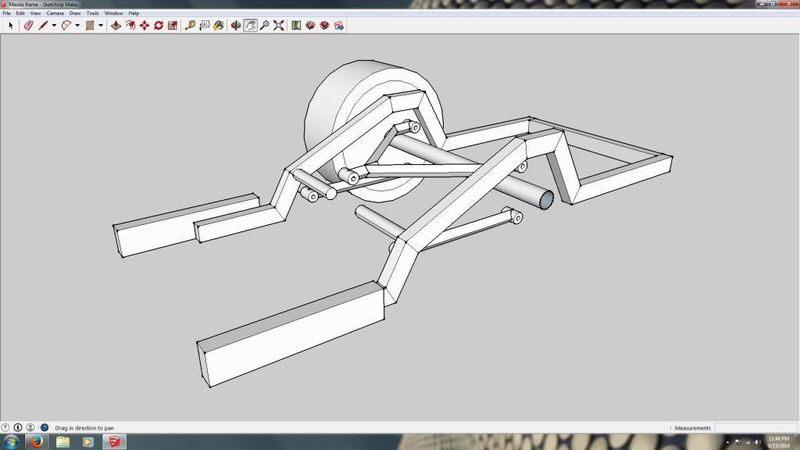

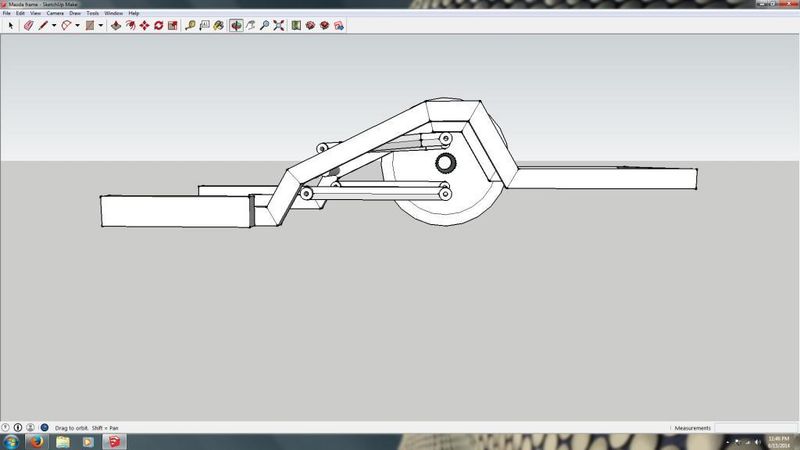

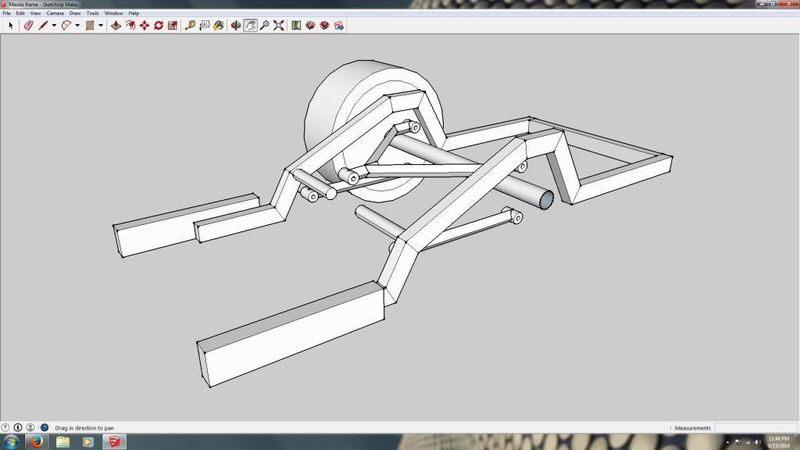

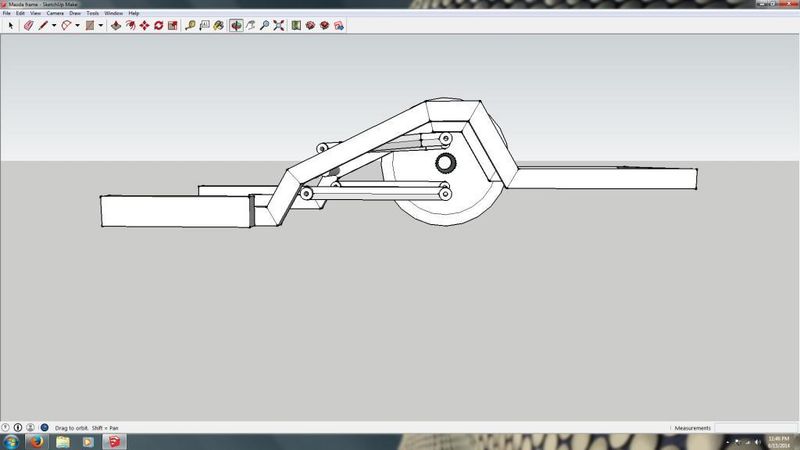

Ok, so Ive run into some problems with the backhalf that I messed up on some years ago and jus now finding out. And Im tired of dealing with stupid crap like this so I've decided I'm cutting the whole backhalf off and starting over from scratch. Revamping the whole design. Luckily the axle tabs and 3 link are gonna work, there is nothing wrong with them, so I am reusing them. I've drawn the new frame design up on Google Sketchup. The 3 link/driveshaft crossmember was being difficult to draw, for a novice, so its only half there. But this is what Im going to do now. I've already bought the new 2x3x11ga tubing. I'm hoping to start on it in 2 weekends from now.

The frame is made to tuck a 28" tall tire, which means 22s..... nom nom nom

The frame is made to tuck a 28" tall tire, which means 22s..... nom nom nom

vsawmike

+1y

Looks good. Make sure the top bar is very strong material or when you take turns hard it will flex enough to allow the tires to hit the frame on one side and/or the body on the other.

bodied b2600zx (josh)

+1y

The 3 link is made out of 1.5x1.5x1/4 tubing. Only flex will be in the bushings but that's not avoidable. I have never had a truck rub the body or frame. If you get that much lateral movement out of the axle, your link is very wrong.

modplant

+1y

That looks really good man, I have sketch up too but suck at it. Got any tips for drawing a frame with it?

Sent from my SGH-T839 using Tapatalk 2

Sent from my SGH-T839 using Tapatalk 2

vsawmike

+1y

Yes that plenty strong enough. I have seen many links like that that flex too much. Mostly narrower thinner tube. Long links will flex much more than you might think. Most of the time it's not noticed until a hard corner is taken and it ruins a wheel, tire or bed side.

best way to check is grab the back of the frame and shake it back and forth real hard to see how much flex there is.

the tube you are using is plenty strong.

J

jiffyzx6

+1y

How much do you want for your Hobart 140? I'll give ya some money for new parts lol need a welder bad...

bodied b2600zx (josh)

+1y

This was the first time I've drawn a frame. The frame itself was easy. Jus used the rectangle tool and drew out the frame width and overall length, pulled it up to the right height, then used the line tool and the tape measure to start drawing the frame rail out, then jus pushed the parts I didn't need out.

Doing the 3 link was def trickier. I watched some tutorial videos on the sketchup page that helped a lil. But it was jus trial and error.

bodied b2600zx (josh)

+1y

I already have a line of guys at work wanting it. Haha. Shoulda asked more for it! Lol

Related Discussions in Mazda Projects

Thread

Posts

Last Post

852

last post by

skrapinsask +1y

150

last post by

cherokeed +1y