K

SFBD square with a Cummins and custom chassis

BD

bagged dually

+1y

We're staying in a cabin out of Internet range right now but as soon as I get back to a wifi ill post some of this stuff I've gathered. Trying to do it from my phone would take me a year.

comegetsome

+1y

Could one of you guys email my the diagrams so ill have them if i need them....thanks

BD

bagged dually

+1y

Ill email them to you also as soon as I can get them off of my iPad lol. No Internet till tomorrow but ill get them out to everyone.

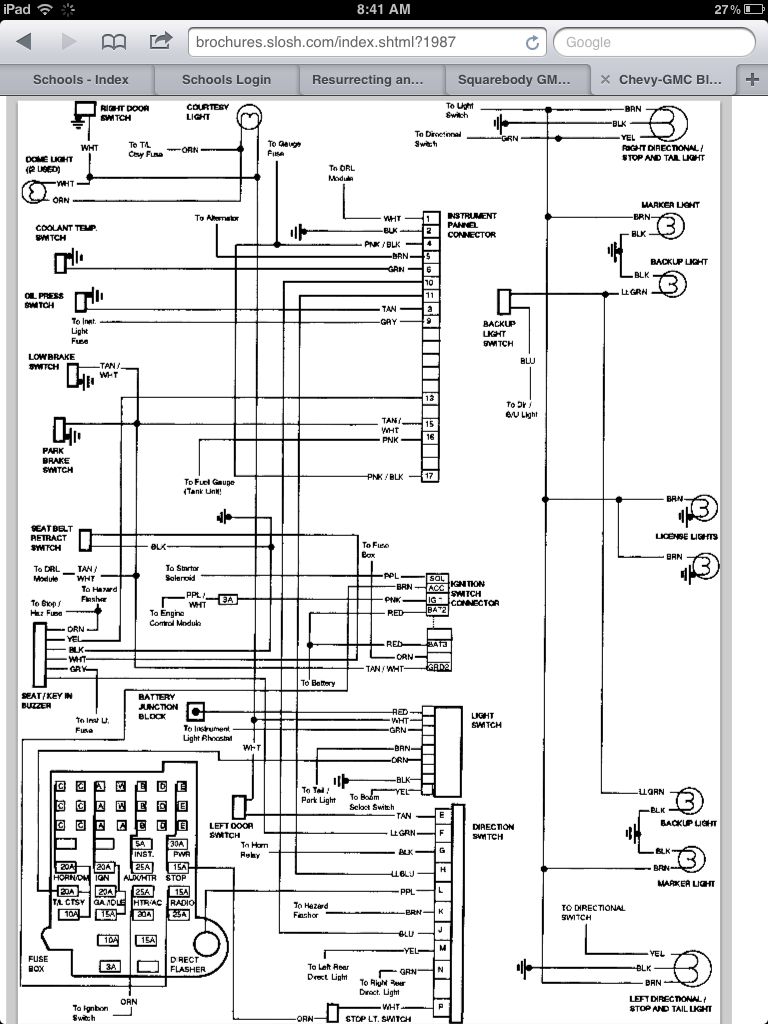

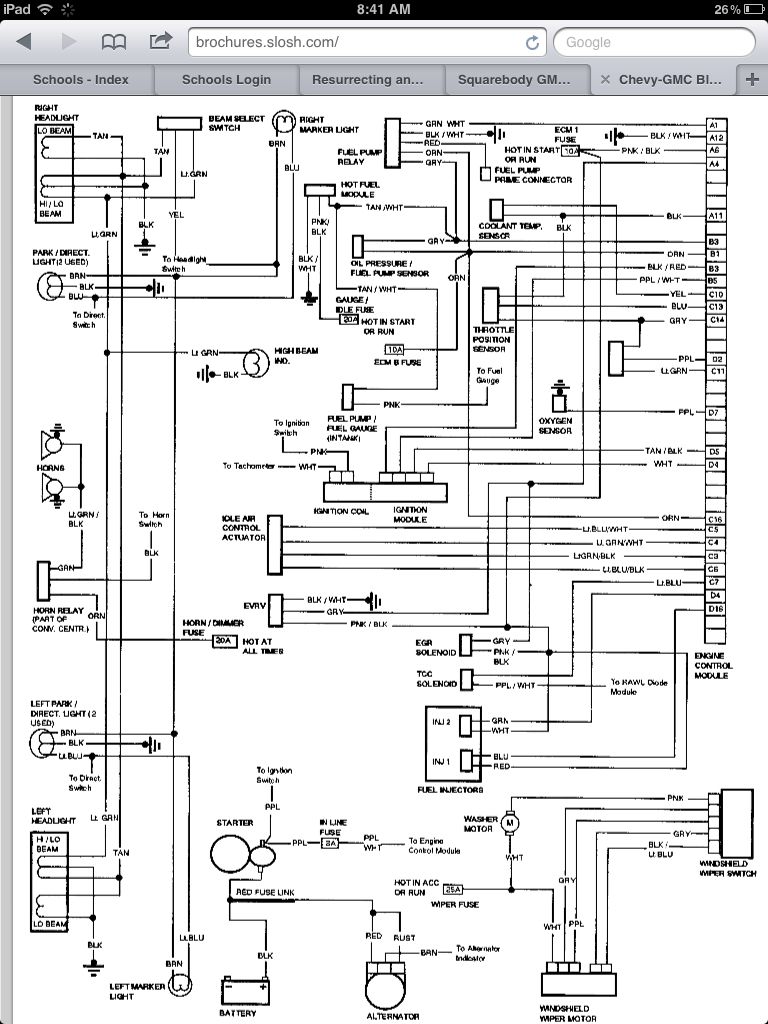

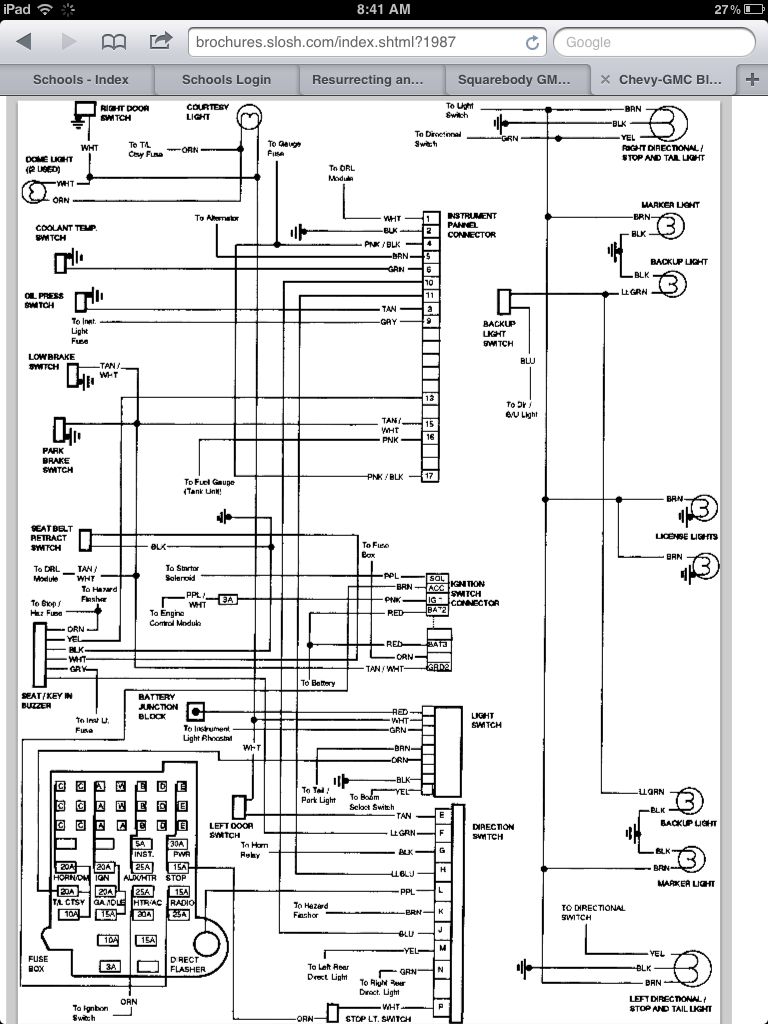

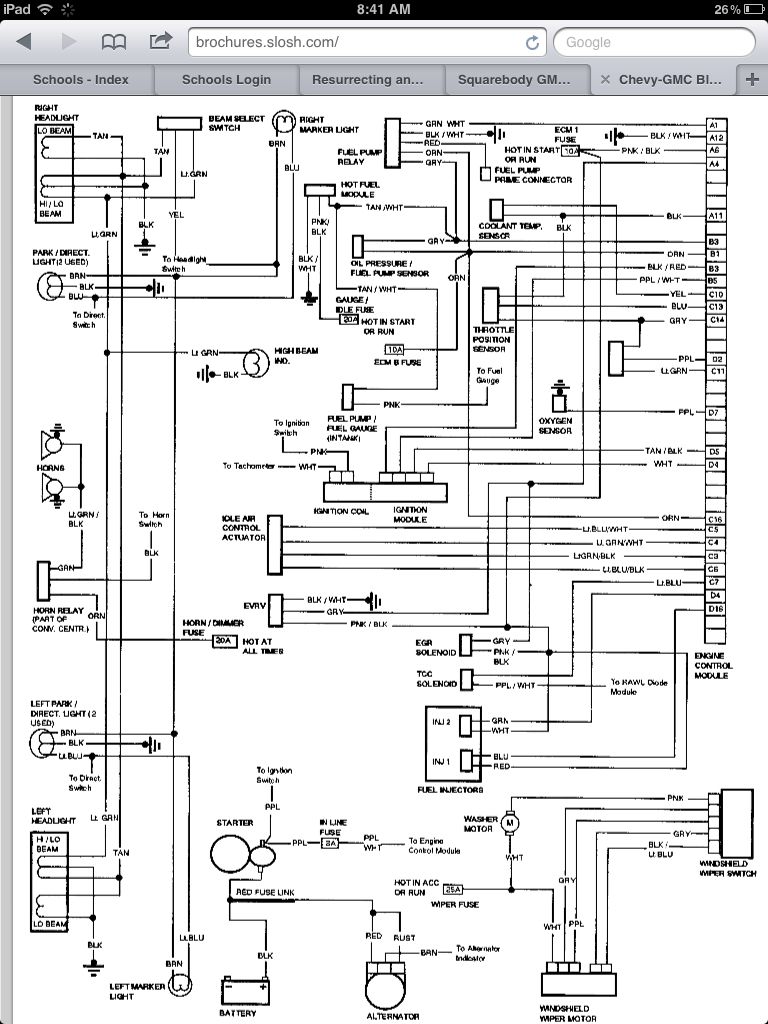

This is a link to one of my other build threads over at 4BT Swaps. One of the guys over there was gracious enough to scan all of the wiring diagrams out his Chevy service manual and post them all on my page. If anyone wants to go get them before I get back to an Internet connection feel free to. That's some of the wiring info I have.

natoinc

+1y

You mind including me in the email also. Im dropping an '83 square body dually and diagrams would sure come in handy. Thanks-

BD

bagged dually

+1y

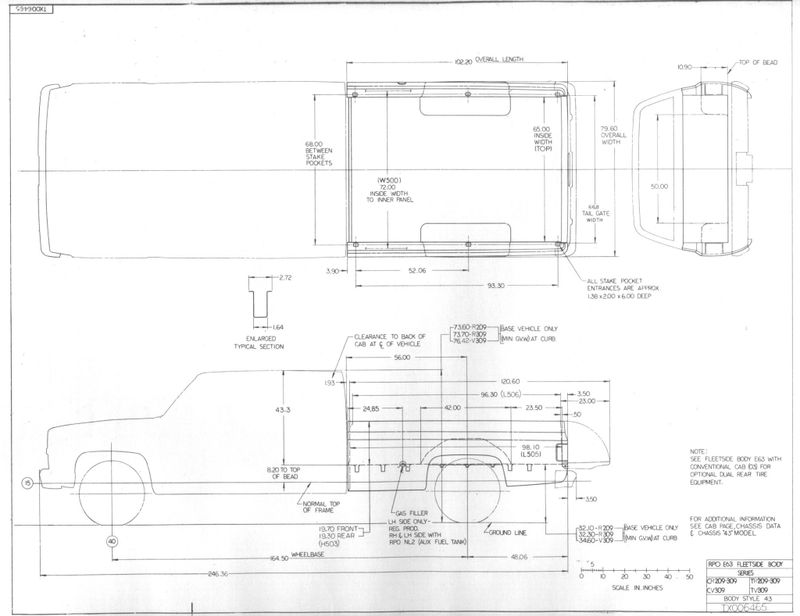

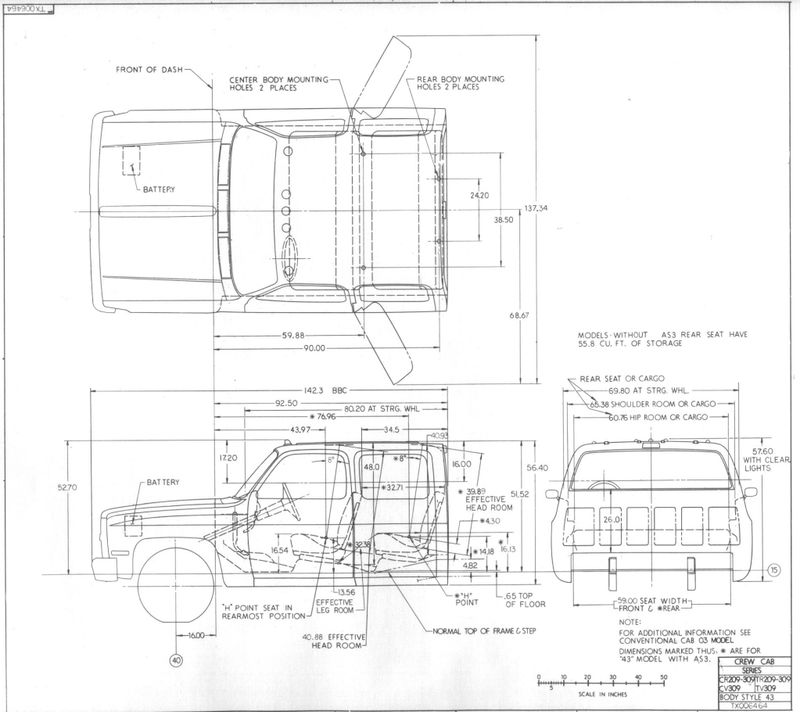

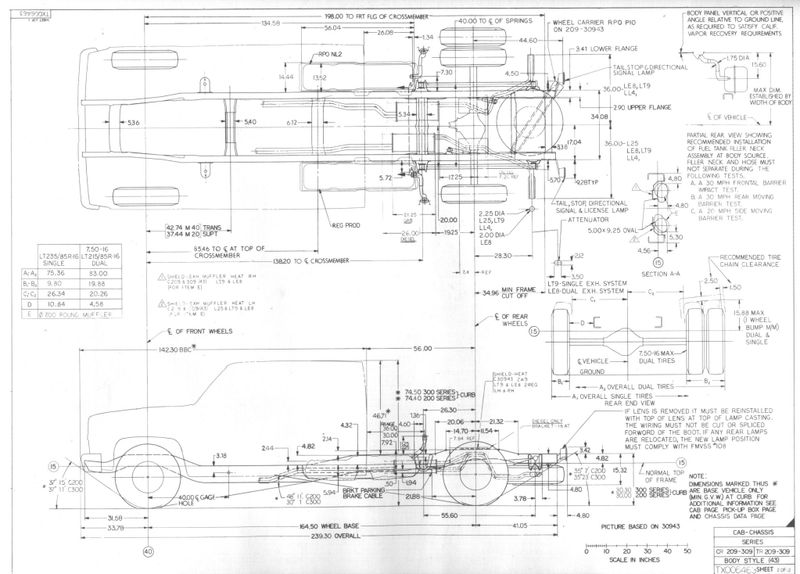

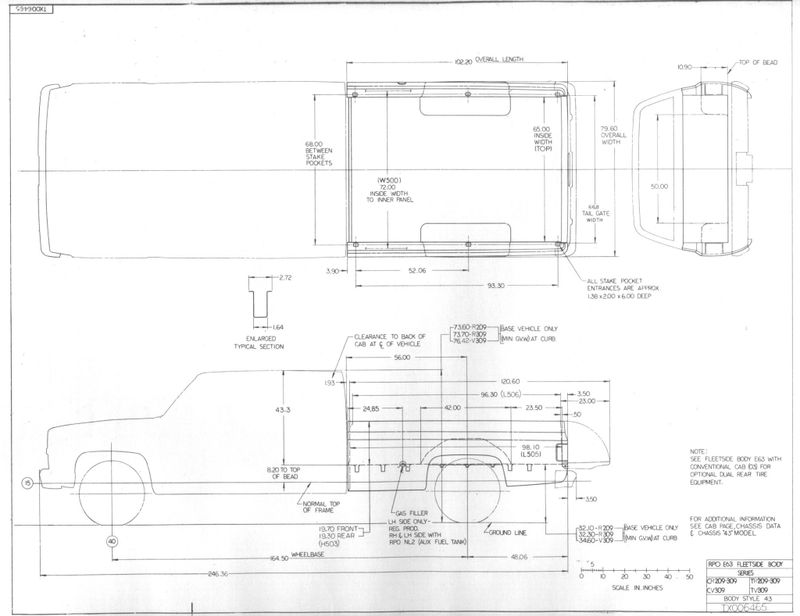

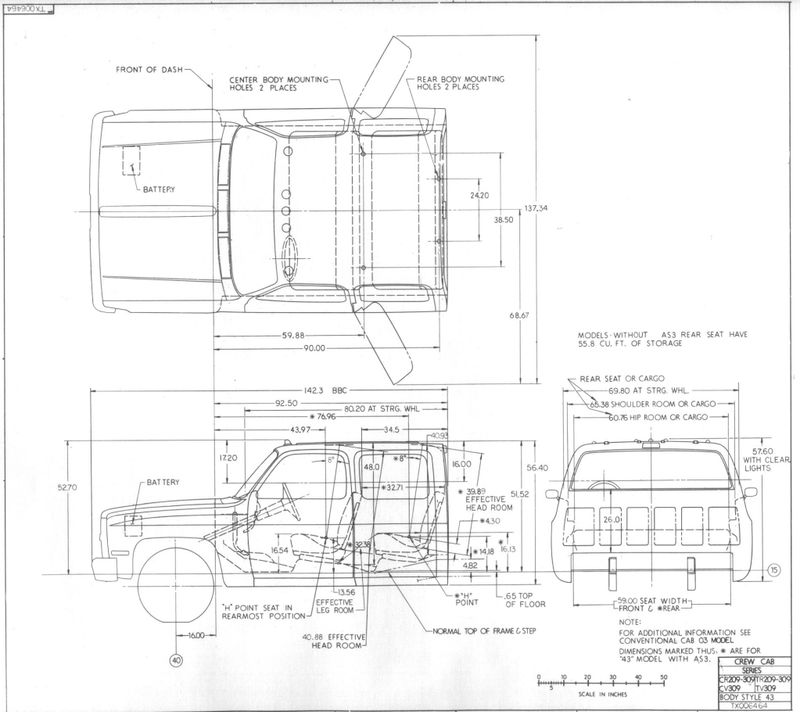

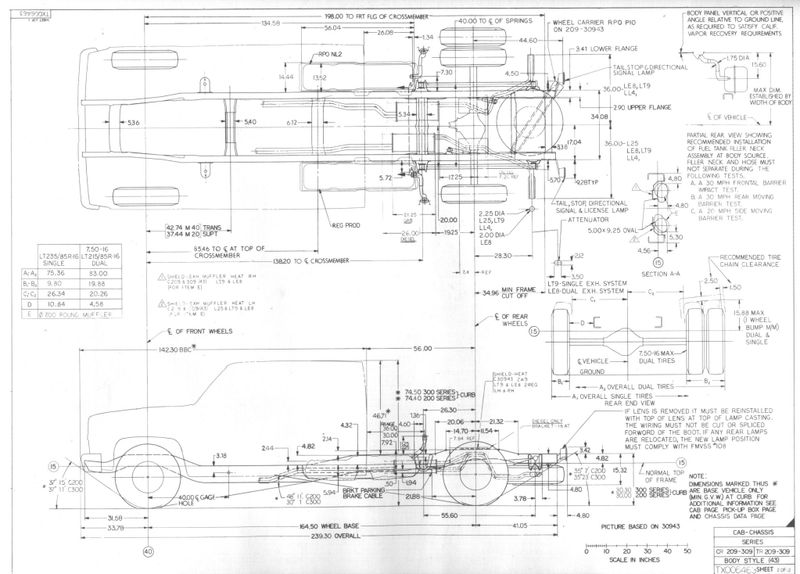

Someone staying with us had a mobile hotspot so ill put a couple of these up. I'll have to get to my computer to get the rest. These dimensions I have are really bad ass although I'm not sure how much real use they have other than being neat to check out. They may come in handy to someone at some point.

When I get back home around my computer ill get a big group email together with all of the square body and cummins wiring stuff I have and get it sent out. If anyone else wants it sent to them also just PM me your email address.

Let me know what you think about these dimensions

When I get back home around my computer ill get a big group email together with all of the square body and cummins wiring stuff I have and get it sent out. If anyone else wants it sent to them also just PM me your email address.

Let me know what you think about these dimensions

BD

bagged dually

+1y

Alright guys. Tomorrow I'd like to start finishing up my 4 link. I have a couple of questions before I do my up bars though. You guys are for sure the group of guys I turn to when I have a suspension question. My lower link bars are outside my frame, have the bags mounted on them, and most importantly facing forward. My upper link bars have yet to be fabbed and this is where I've hit a snag. I was going to just build a basic triangular 4 link with all the bars going forward. The more I think about it the more I like the idea of making my upper link bars a wishbone setup. Is there a downside to that over 2 seperate bars?? Also when I set it up in either configuration does it really matter if the spread out ends and the close ends are on the axle or the frame side??

Next is my most puzzling issue, to me anyway. Could I run my upper link bars or wishbone to the rear of the truck?? I have a very limited amount of room in front of the axle but no plans for behind the axle so the space is unlimited back there. I know that 4 links that are completely reversed can cause some issues when braking and the way the axle pivots in hard braking. But with my lower bars forward and my rear bars backwards what is the downfall if any?? Will it mess with my braking, or pinion angle, or anything else.

I'd for sure like to get you gents take on this before I start chopping steel.

Also my lower bars are 2" square stock 1/4" thick with the bags on the bars and all 3" end links. I plan on fabbing my uppers out of 1.5" square 3/16" thick with the same 3" end links. If I remember correctly my lower bars are about 36" long and my uppers will be about the same. Does anyone see any issue with any of that or my uppers being smaller?? I figured the uppers would be alright being fabbed with the smaller steel stock.

Thanks in advance guys.

Next is my most puzzling issue, to me anyway. Could I run my upper link bars or wishbone to the rear of the truck?? I have a very limited amount of room in front of the axle but no plans for behind the axle so the space is unlimited back there. I know that 4 links that are completely reversed can cause some issues when braking and the way the axle pivots in hard braking. But with my lower bars forward and my rear bars backwards what is the downfall if any?? Will it mess with my braking, or pinion angle, or anything else.

I'd for sure like to get you gents take on this before I start chopping steel.

Also my lower bars are 2" square stock 1/4" thick with the bags on the bars and all 3" end links. I plan on fabbing my uppers out of 1.5" square 3/16" thick with the same 3" end links. If I remember correctly my lower bars are about 36" long and my uppers will be about the same. Does anyone see any issue with any of that or my uppers being smaller?? I figured the uppers would be alright being fabbed with the smaller steel stock.

Thanks in advance guys.

BD

bagged dually

+1y

A person with a whole lot of suspension knowledge over on another forum told me to not ever run any of them backwards and always run them toward the center of the vehicle. With a little explanation of why it needs to be that way it made sense to me. So it looks like ill be running all of y bars forward.

Can anyone tell me if it will make much of a difference if I run a true triangular 4 link or if I make my upper links into a wishbone?? Also does it matter if the narrow or spread out ends of the upper bars to on the axle or frame??

Can anyone tell me if it will make much of a difference if I run a true triangular 4 link or if I make my upper links into a wishbone?? Also does it matter if the narrow or spread out ends of the upper bars to on the axle or frame??

guilty by design

+1y

Running your wishbone backwards like that would get your a 50/50 link setup and they are junk. The opposing bar arcs will roll your pinion angle alot harder than a foward facing link setup would and in alot of instances a 50/50 link would cause your suspension to unload under heavy braking.

Making the top bars separate or together really doesnt have an affect on the truck, its just a matter of what you can fit. Remember that if you build a wishbone it does not have to be symmetrical. It can be in the shape of an A, h, or anything you need it to be the wishbone only knows the 3 points of contact with the truck. I think your overkill on the uppers, id build it out of 1 1/2'' round bar with a .120 wall and feel comfortable. If your uppers are a little shorter you can make the front mounts a little closer together to take some pinion roll out of the setup.

Making the top bars separate or together really doesnt have an affect on the truck, its just a matter of what you can fit. Remember that if you build a wishbone it does not have to be symmetrical. It can be in the shape of an A, h, or anything you need it to be the wishbone only knows the 3 points of contact with the truck. I think your overkill on the uppers, id build it out of 1 1/2'' round bar with a .120 wall and feel comfortable. If your uppers are a little shorter you can make the front mounts a little closer together to take some pinion roll out of the setup.

BD

bagged dually

+1y

Well I made it out to Guilty by Design today and got a couple more brackets and an end link. I think that should be the rest of what I need to get my 4 link finished up. I still need some shock tabs and little stuff but ill have to get a parts list together and go get everything in one trip when I've got it tore back down to the frame.

Tomorrow a few buddies are supposed to be coming over to help me finish the floor pans up.

I got a cross member tacked together today to attach the front of my upper link bars to. Ill snap a few pix tomorrow.

Thanks for letting me check out the shop today Kyle. Really sick projects and amazing parts.

Tomorrow a few buddies are supposed to be coming over to help me finish the floor pans up.

I got a cross member tacked together today to attach the front of my upper link bars to. Ill snap a few pix tomorrow.

Thanks for letting me check out the shop today Kyle. Really sick projects and amazing parts.

BD

bagged dually

+1y

I got a lot more of my trans tunnel done yesterday. I'm hoping to finish up the drivers side of it today. I also got the first section of driveshaft tunnel welded in. I had to cut the floor pan cross member out that sits in line with the B pillar. I used some 5/16" flat stock and made it as strong as I could with hitting the shaft and not making the new floor pan terribly wierd looking.

It's taking me a lot of extra time to make all of my floor pan rounded instead of squared off but I really want my carpet to lay down and look stock. Doing it in small sections has really made it easier that trying get all of the bends right. I also got all of the seam sealer to finish the floor up a couple days ago. As soon as the floor pan is done it going back on the trailer and headed back to the shop for the winter for final welding, chassis painting, and final assembly.

I think the best news from the last few days is a good buddy has a set of 16" Alcoa's he's going to let me get for my truck until I get my big rig wheels. I can finally get rid of these hideous steel wheels and simulators.

Thanks again Larry. Going to look a lot better with the alcoas.

I took a couple of night time pix for you guys to kinda see where I'm all on the floor pans. Not very good pix but hopefully you guys will get the point.

This is what I've gotten done on the drivers side so far. Ill hopefully finish it up today.

This is the best way I found the patch up the cross member so the floor pan will be rigid. Not the prettiest thing but it'll work. I just patched some 18gauge over the top and ill try to blend it with the rest of the drive shaft tunnel. Not having a pipe bender here makes some of this stuff hard to pull off.

It's taking me a lot of extra time to make all of my floor pan rounded instead of squared off but I really want my carpet to lay down and look stock. Doing it in small sections has really made it easier that trying get all of the bends right. I also got all of the seam sealer to finish the floor up a couple days ago. As soon as the floor pan is done it going back on the trailer and headed back to the shop for the winter for final welding, chassis painting, and final assembly.

I think the best news from the last few days is a good buddy has a set of 16" Alcoa's he's going to let me get for my truck until I get my big rig wheels. I can finally get rid of these hideous steel wheels and simulators.

Thanks again Larry. Going to look a lot better with the alcoas.

I took a couple of night time pix for you guys to kinda see where I'm all on the floor pans. Not very good pix but hopefully you guys will get the point.

This is what I've gotten done on the drivers side so far. Ill hopefully finish it up today.

This is the best way I found the patch up the cross member so the floor pan will be rigid. Not the prettiest thing but it'll work. I just patched some 18gauge over the top and ill try to blend it with the rest of the drive shaft tunnel. Not having a pipe bender here makes some of this stuff hard to pull off.

Related Discussions in Dually Projects

Thread

Posts

Last Post

546

A

last post by

Airnewb91 +1y

193

last post by

Airnewb91 +1y